Tomato paste is a widely used ingredient in the food industry, and setting up a tomato paste production line can be a profitable business. Whether you are planning a small-scale factory or a large-scale industrial plant, tushunish production process, required equipment, and costs is essential. This guide will walk you through everything you need to know to start your tomato paste manufacturing business.

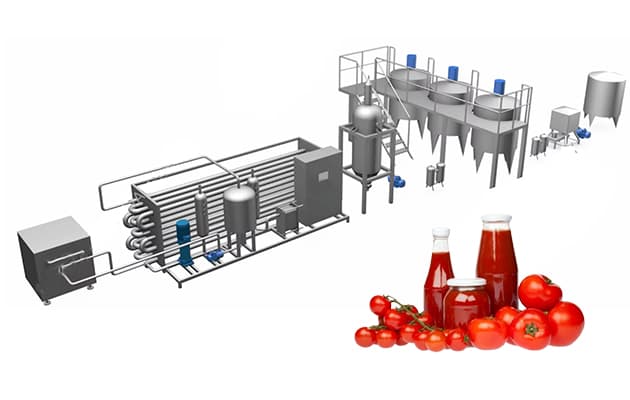

1. What is Tomato Paste Production Line?

A tomato paste production line is a system of machines designed to process fresh tomatoes into concentrated tomato paste. This paste can be packaged and sold directly or used as a raw material for ketchup, sauces, and other tomato-based products.

Key Benefits of Investing in a Tomato Paste Production Line:

- High market demand for tomato-based products

- Long shelf life for processed tomato paste

- Scalable production for small and large businesses

- Potential for exports and high-profit margins

2. The Complete Process of Tomato Paste Production

Step 1: Washing & Sorting

Fresh tomatoes must be thoroughly washed to remove dirt, pesticides, and other contaminants. Sorting machines help separate high-quality tomatoes from defective ones.

Required Equipment: Washing machine, Sorting machine

Step 2: Crushing & Preheating

Selected tomatoes are crushed into a pulp and preheated to deactivate enzymes and enhance color retention.

Required Equipment: Crusher, Preheater

Step 3: Pulping & Refining

The tomato pulp is refined to remove skins, seeds, and fibrous material, ensuring a smooth and consistent paste.

Required Equipment: Pulper, Finisher

Step 4: Concentration & Evaporation

The extracted tomato pulp is heated in an evaporator to remove excess water, resulting in concentrated tomato paste with a high solid content (typically 28%-30%).

Required Equipment: Vacuum evaporator

Step 5: Sterilization & Aseptic Filling

To extend the shelf life, the paste is sterilized at high temperatures and then packaged in aseptic bags, cans, or glass jars.

Required Equipment: Sterilizer, Aseptic filling machine

Step 6: Packaging & Labeling

Final products are packed into different sizes based on market needs, then labeled and prepared for distribution.

Required Equipment: Packaging machine, Labeling machine

3. Essential Equipment for a Tomato Paste Production Line

| Equipment | Function |

|---|---|

| Washing Machine | Cleans fresh tomatoes |

| Sorting Machine | Separates good tomatoes from defective ones |

| Crusher | Crushes tomatoes into pulp |

| Preheater | Heats pulp to improve color and consistency |

| Pulper & Finisher | Removes seeds and skin |

| Evaporator | Concentrates tomato paste |

| Sterilizer | Kills bacteria and extends shelf life |

| Aseptic Filling Machine | Packs paste into sterile containers |

| Qadoqlash mashinasi | Prepares final products for sale |

4. How to Choose the Right Tomato Paste Production Line

When selecting equipment, consider the following factors:

1. Ishlab chiqarish quvvati

- Small-scale: 100-500 kg / h

- Medium-scale: 500-2,000 kg / h

- Large-scale: 2,000+ kg / h

2. Avtomatlashtirish darajasi

- Semi-automatic: Lower cost, more manual labor required

- To'liq avtomatik: Higher efficiency, minimal labor involvement

3. Power Supply & Isitish usuli

- Elektr isitish: Requires industrial 3-phase power

- Gas heating: Suitable for regions with limited electricity supply

5. Tomato Paste Production Line Cost

The total cost depends on production capacity, equipment quality, and automation level. Here’s an estimated price range:

| Ishlab chiqarish shkalasi | Estimated Cost (USD) |

| Small-Scale (100-500 kg / h) | $10,000 – $50,000 |

| Medium-Scale (500-2,000 kg / h) | $50,000 – $500,000 |

| Large-Scale (2,000+ kg / h) | $500,000 – $2,000,000 |

Additional costs include:

Maintenance and spare parts

Raw materials (tomatoes, packaging materials)

Labor and factory setup

6. Frequently Asked Questions (FAQs)

Q1: How much space is needed for a tomato paste production line?

- A small-scale plant can operate in 200-500 square meters, while a large industrial setup may require 2,000+ square meters.

Q2: Can I start with automatic production line?

- Ha, Fully automatic production line is a good choice, saving labor costs

Q3: What is the best packaging option for tomato paste?

- Popular choices include aseptic bags (200L), tins (70g-5kg), and glass jars (300g-1kg).

Q4: How long does tomato paste last?

With proper sterilization and packaging, tomato paste can last 12-24 oylar.

7. Conclusion – Get Your Tomato Paste Production Line Today!

Setting up a tomato paste production line is a profitable investment with growing market demand. Whether you are looking for small-scale processing or large-scale industrial production, choosing the right equipment and setup is crucial.

🚀 Want to start your own tomato paste business? Contact us DT Food Machine today for a customized production solution and free quotation!

📩 Get a Free Quote Now!