Kirish

If you’re running a food production business or planning to start one, automating your operations with a Spring Roll mashinasi could significantly boost efficiency, cut labor costs, and maintain consistent product quality. From small restaurants to large-scale factories, the demand for spring roll machines is growing as global consumption of frozen and ready-to-eat snacks continues to rise.

Ushbu maqolada, we’ll walk you through how to choose the best spring roll machine for your specific business needs. We’ll also break down popular long-tail keywords like automatic spring roll machine, commercial spring roll machine, spring roll wrapper making machine, and more to help you understand their differences and applications.

1. What Is a Spring Roll Machine?

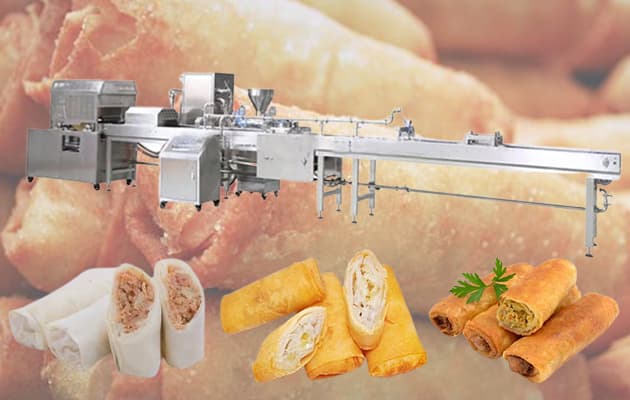

A spring roll machine is a food processing machine designed to automate the steps of making spring rolls—typically including wrapper preparation, filling, folding, yalang'och, and sometimes sealing. These machines can be semi-automatic or fully automatic, depending on the size and type of your operation.

A standard spring roll machine can handle thousands of units per hour and is essential in large commercial kitchens, frozen food factories, and snack processing facilities.

2. Types of Spring Roll Machines

🔹 Automatic Spring Roll Machine

An automatic spring roll machine performs every step—from preparing the wrapper to rolling and sealing the product. It’s perfect for medium to large factories aiming for high-volume, consistent output. These machines can produce between 2,000 uchun 6,000 spring rolls per hour.

Key Benefits:

- Fully automated process

- High production capacity

- Reduced labor dependency

- Uniform shape and weight

Ideal For:

- Frozen food manufacturers

- Export-oriented factories

- Catering businesses with bulk orders

🔹 Semi Automatic Spring Roll Machine

A semi automatic spring roll machine requires partial human intervention—usually for placing or adjusting the filling. It’s cost-effective and suitable for small businesses or those starting out.

Key Benefits:

- Lower cost

- Easier to maintain

- More flexibility for customization

Ideal For:

- Small-scale food businesses

- Street food vendors

- Restaurants wanting higher output without full automation

3. Bahor rulosi o'rash mashinasi

A spring roll wrapper making machine focuses only on producing the thin wrappers (also known as skins or sheets) used in spring rolls. These can then be used with manual or separate machines for filling and rolling.

Asosiy xususiyatlar:

- Adjustable thickness

- Various sizes available

- Often includes a batter feeding system

Why You Might Need One:

If your business prefers to handle the filling and rolling manually, or if you’re producing wrappers for resale, this machine is a must-have.

4. Commercial Spring Roll Machine

A commercial spring roll machine is a broad term referring to machines used in business settings. They range from small models for restaurants to high-capacity industrial lines.

When searching for the best commercial spring roll machine, focus on:

- Output capacity (E.G., 1,000 uchun 10,000 pcs/hour)

- Durability and hygiene standards (stainless steel, food-grade parts)

- Ease of cleaning and maintenance

- Warranty and after-sales support

5. Industrial Spring Roll Machine

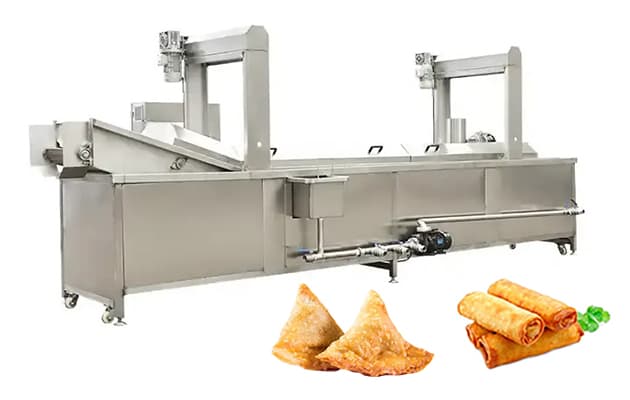

An industrial spring roll machine is built for continuous 24/7 operation. These are large-scale machines integrated into full spring roll production lines, often including:

- Batter mixer and wrapper machine

- Cooling conveyor

- Filling feeder

- Folding and rolling system

- Packaging unit

Best For:

- Mass production factories

- Exporting frozen spring rolls

- OEM spring roll manufacturers

6. Spring Roll Machine for Small Business

If you’re starting small, don’t worry—there are compact and affordable spring roll machines for small businesses. They often produce 300–1,000 rolls per hour and can be placed on a countertop.

Consider:

- Portability

- Low energy consumption

- Easy operation

- Versatile use (may handle samosas or dumplings too)

Pro Tip:

Start small, then scale as your orders grow. Many brands offer modular upgrades.

7. Mini Spring Roll Machine

A mini spring roll machine is a perfect choice for restaurants, Oziq-ovqat yuk mashinalari, or test kitchens. It’s lightweight, affordable, and ideal for small-batch production.

Features to Look For:

- Easy to disassemble and clean

- Compact design

- Adjustable speed and roll size

- Affordable price (typically under $2,000)

8. Spring Roll Pastry Machine

A bahorgi rulon pirojnomasi specializes in creating uniform spring roll skins or wrappers. It typically includes:

- Batter tank

- Heating drum

- Cutting and rolling units

- Conveyor

Many bakeries or central kitchens use these machines to produce high-quality pastries consistently.

9. Frozen Spring Roll Machine

If your business produces frozen spring rolls, you’ll need a machine that can produce, cool, and prepare the rolls for packaging and freezing. Look for models with:

- Integrated cooling conveyors

- Hygienic, food-safe materials

- Precise shape and filling control

Frozen products require machines that can consistently create uniform weight and sealing to ensure product longevity.

10. Spring Roll Wrapping Machine

The spring roll wrapping machine focuses on one specific task—wrapping the filling in the pre-made wrapper. It’s great for businesses that make their own wrappers separately but want consistent rolling quality.

Benefits:

- Fast and accurate wrapping

- Reduced manual labor

- Ideal for assembly line integration

11. Spring Roll Machine Price Guide

The price of spring roll machines varies widely based on type, capacity, and brand:

| Machine Type | Price Range |

|---|---|

| Mini Model | $800 – $2,000 |

| Semi-Automatic | $3,000 – $6,000 |

| Automatic | $7,000 – $20,000+ |

| Industrial Line | $30,000 – $100,000+ |

If you need more detail, please contact us!

Always ask for:

- Shipping costs

- Warranty & ehtiyot qismlar

- Installation support

- Training and manuals

12. Spring Roll Machine Manufacturers

If you’re looking to import or wholesale machines, top countries known for spring roll machine manufacturers include:

- Xitoy (DT oziq-ovqat mashinasi, most cost-effective)

- Taiwan (higher quality, precise engineering)

- Germany (top-tier industrial machines)

- India (affordable and serviceable locally)

DT are among the trusted names in the market.

13. Key Considerations When Choosing a Spring Roll Machine

✅ Production Capacity

Estimate how many rolls you need per hour/day.

✅ Type of Product

Vegetarian, meat-based, mini rolls, dessert-style—this affects the filling system.

✅ Available Space

Measure your kitchen/factory space before buying.

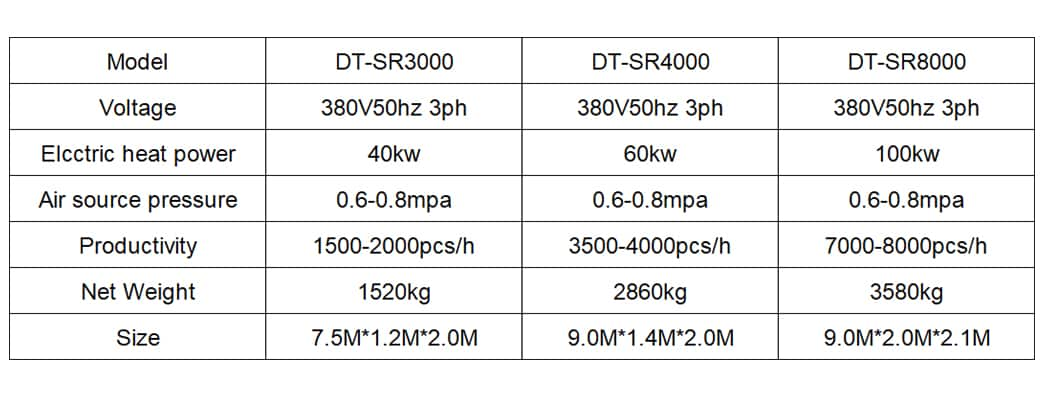

✅ Power & Energy Use

Check the voltage and kW usage—especially for industrial machines.

✅ Hygiene Standards

Food-grade stainless steel is a must. Ensure easy cleaning and maintenance.

✅ Support & Warranty

Choose a manufacturer offering strong after-sales service.

14. Bonus: Spring Roll Production Line Setup

If you’re planning to scale up, here’s what a typical spring roll production line includes:

- Batter mixing system

- Wrapper making machine

- Cooling conveyor

- Filling machine

- Rolling & folding unit

- Packaging machine

- Freezing tunnel (for frozen products)

Each machine should integrate smoothly for maximum efficiency.

Xulosa

Choosing the right spring roll machine for your business is a strategic investment. Whether you’re a small eatery or a large-scale factory, there’s a model suited for your goals. Focus on your production needs, budget, space, and product type when selecting the ideal machine.

With the right machine, you’ll increase output, ensure consistent quality, and meet market demands with ease.