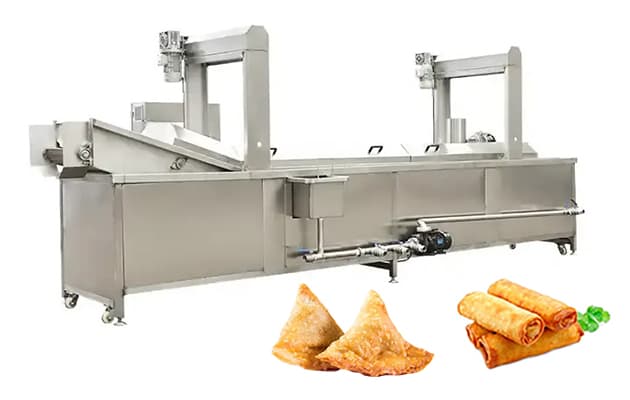

Spring Roll Making Machine Spring Roll Machine Lumpia Making Machine

Spring roll making machine consists of batter beating machine, spring roll wrapper machine, stuffings filling, wrapper folding machine, rolling machine and spring rolls conveyor belt.

Ariza: Machine making spring rolls, mini spring rolls, finger spring rolls, egg rolls, lumpia, suitable for various stuffings

Sig'im: 1500pieces to 8000 bir soat

Material: Oziq-ovqat darajasi zanglamaydigan po'lat 304

Control Method: PLC control system

Isitish usuli: Electromagnetic Heating

Kuchlanishi: 380V 50HZ 3Ph, different voltage needs transformer

Spring Roll Making Machine Making Spring Rolls

Spring Roll Making Machine produces spring rolls with delicate wrapper and myriad of flavors. To suit various tastes and dietary preferences in different regions, we have adapted our spring roll making machines to some of the most popular fillings and spring roll types, including but not limited to the following:

Shrimp Spring Rolls: Stuffings are mixture of chopped shrimp and vegetables like celery, carrots, and onions.

Chinese Spring Rolls: Classic spring rolls stuffings are vegetables like cabbages, carrots, bean sprouts etc, or red bean paste spring rolls etc.

Fried Spring Rolls/Egg Rolls: As Basic food for many Asian restaurants and takeaways. Its stuffings are mixture of vegetables and meat, or seafood. And fried spring rolls are deed fried until crispy and golden color.

Fresh Veggie Spring Rolls: As healthier food, stuffings are with fresh vegetables fillings such as cucumber, avocado and mango, wrapped in rice paper.

Cocktail spring rolls: They are served as finger food, with mixture of seafood, sabzavot, herbs and other flavors.

Large or giant spring rolls: Fillings are with various ingredients, for example meat, mixture of meat and vegetables, even noodles.

Mini vegetable spring rolls: As heathy and delicious food, they are ideal choice for snack or meal. The stuffing is typical mixture of fresh vegetables and other flavors.

The automatic spring roll machine is ideal choice to use in food making factories, central kitchens and restaurant who need to produce fresh spring rolls, frozen spring rolls and fried spring rolls in large quantities.

What is a Spring Roll Making Machine ?

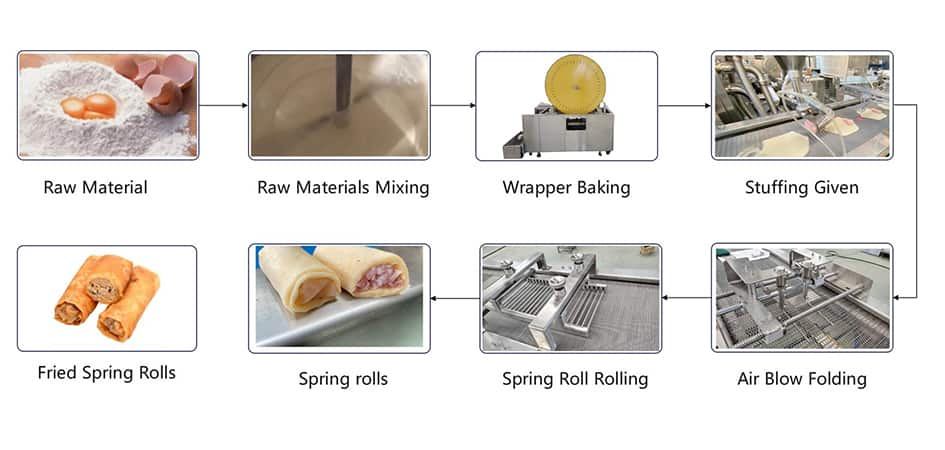

Spring roll making machines include Automatic spring wrapper production system, stuffing depositing system, spring rolls folding and wrapping system.

Spring roll machine automates the process of baking the spring roll wrapper pastry, depositing stuffing with adjustable amount, wrapping and folding the spring roll skin around a filling. At a result, it significantly reduces the time and effort required to produce large quantities of spring rolls. With its precision and efficiency, spring roll making machines have become an favorable tool for restaurants and food manufacturers.

The Spring Roll Machine Consists of the Following

Batter Mixer: 100L, Speed 2900rounds per minute.

Pumping system: 055Kvant

Batter dough dispenser and Nozzles: Adjustable wrapper thickness

Spring Roll Skin Baking drum/Forming Machine: Electric heating 380V 50HZ 3ph

Spring roll Sheet cooling conveyor: Cooling the wrapper before stuffings feeding

Stuffing filling mechanism: Adjustable stuffings amount to achieve best tasture.

Pneumatic folding System: Decides the length of spring rolls, adjustable folding devices to achieve best size.

Wrapper Rolling Unit: Adjustable wheels to adjust diameter of spring rolls. Make sure spring roll wrapper tighly rolled.

End Product conveyor: To send finish product to next stage

Spring Roll Making Machine Features

High-Efficiency:

Compared to traditional manual wrapping, automatic spring roll machines can produce a large number of spring roll wrappers in a short period of time, greatly improving production efficiency. This is undoubtedly a huge advantage for the catering industry and food processing industry.

Precise Control:

Modern automatic spring roll machines are equipped with advanced control systems(PLC control system) that can precisely control key parameters such as baking temperature and humidity, ensuring the stability of spring roll wrapper quality, stuffing amount to keep sure the end spring roll weight accurate and uniform shape. The precise control guarantees the taste and appearance of spring rolls but also reduces waste.

Diverse Design

DT automatic spring roll machines are customizable special specifications, to make mini spring rolls to giant spring rolls, and different stuffings like vegetables, meat, banana paste, and mixture of vegetable and meat etc. Bundan tashqari, we have developed models to cover different production ranging from 1000pcs to 2000pcs per hour, 3000 to 4000pcs per hour, 6000 to 7000pcs per hour, 8000 to 9000pcs per hour and higher.

Adjustable Settings

Adjustable settings is customized to meet different customer requirement on size of the spring rolls, the amount of filling, and even the tightness of the wrap, ensuring versatility and precision.

Gigiena va xavfsizlik

Spring roll machines are designed with hygiene in mind. The machine is designed and made with food grade 304 Zanglamaydigan po'latdan yasalgan materiallar, and waterproof grade IP5 allow water spray to clean the machine from all direction (except baking machine). Easy-to-clean surfaces and materials is to resist the growth of bacteria. Qo'shimcha, there are two worker needed to regularly feed batter and stuffings, adjust parameter and monitor the working process in this line. Oxir-oqibat, bu oziq-ovqat bilan inson aloqasini minimallashtiradi, ifloslanish xavfini kamaytirish.

Cost-Effectiveness

Investing in spring roll making machines will be paid back soon by its increased production efficiency, reduced labor costs, and minimized food waste

Automatic Spring Roll Making Machine Specification

Aralashtirish 100L

Kuchlanishi | Kuch | Mixing Speed | Sig'im |

380V 50HZ 3ph | 3kvant | Up to 2900r/min | 100L /Batch (15min) |

Spring Roll Making Machines on Model DT-SR2000

Kuchlanishi | Isitish quvvati | Pneumatic | Stable Capacity | O'lchov | Net Weight |

380V 50HZ 3ph | 40kvant | 0.6 to 0.8mpa | 1500-2000PCS / H | 7500*1200*2000mm | 1550kg |

Spring Roll Making Machines on Model DT-SR4000

Kuchlanishi | Isitish quvvati | Pneumatic | Stable Capacity | O'lchov | Net Weight |

380V 50HZ 3ph | 60kvant | 0.6 to 0.8mpa | 3500-4000PCS / H | 9000*1400*2000mm | 2900kg |

Spring Roll Making Machines on Model DT-SR8000

Kuchlanishi | Isitish quvvati | Pneumatic | Stable Capacity | O'lchov | Net Weight |

380V 50HZ 3ph | 100kvant | 0.6 to 0.8mpa | 7000-8000PCS / H | 9000*2000*2100mm | 3580kg |

DT Spring Roll Making Machine Manufacturer

1. Consistency in Quality:spring roll making machines produces uniform and accurate size and weight of spring rolls.

2. Durable and Stable in working. It ensure the production capacity and less maintenance cost.

3. Guarantee in service: The machine enjoy 12 months quality guarantee. Bundan tashqari, we offer Installation Guide, service and whole life technical support, and whole life spare part supply.

4. More value to customer: DT Ovqat mashinalari to'liq ishlab chiqarish liniyasining to'liq eritmasini taklif etadi, Sizning oziq-ovqat mahsulotlarini ishga tushirish va muvaffaqiyat qozonish uchun sizga bahorgi rulon retseptlari.

DT Spring Roll Machine Price

When it comes to automatic spring roll making machines, “DT Spring Roll Machine” is a well-known brand in the market, and the price of DT Spring Roll Machine is not fixed and is according to following factors.

Model va tikilgan komponentlar

Mijozlar biznesining imkoniyatlariga erishish uchun, we have different models with production ranged from 1000pcs an hour to 9000pcs an hour and higher. Va biz elektr va pnevmatik komponentlarga har bir oziq-ovqat mahsulotlarini qondirish uchun elektron va pnevmatik tarkibiy qismlarga bo'lgan talablarga rioya qilingan brendlarni elektr energiyasini qabul qilamiz. They affect the spring roll making machines price greatly.

Vazifalar va konfiguratsiya

Spring roll maker is required to meet each customer end product, in terms of spring roll size, weight and various stuffing materials requirement. For special size of spring roll, and stuffing materials, the spring roll machine function is required customized to meet these requirements. Additional customized cost is required. Bundan tashqari, due to customer factory site or kitchen space limit, we have to design the production line layout to meet same.

Shu sababli, when choosing DT Spring Roll Machine, you should consider the production capacity of your need, the stuffing materials and end product dimension and weight etc. and your factory voltage and space factors. Communicate with our technical specialist and get more consultancy now.

How to use spring roll making machine ?

The use of fully automatic spring roll machine enable making spring roll simple and efficient. And user shall follow the user manual and operation book. Here is production process in spring roll making factory

Machine preparation

Place the spring roll machines on stable and ground level floor, connected to stable power source. Run few trial tests on each function before officially starch production.

According to the instructions, the well mixed batter is added to batter tank, and preheat the the spring roll sheet making machine about 30 minutes, and the specific time may vary by model.

Food preparation

The freshness and hygiene of the ingredients greatly affect the quality and taste of spring rolls. Shu sababli, the ingredients must be carefully selected, vegetable washed, meat grinded. Vegetable stuffings needs to be dewatered and meat needs to be without fiber, this to ensure the consistent stuffings giving and accurate in end product weight.

Operation technique

When all is ready to go, all the operation shall follow the operation book and adopt preset parameter and settings.

With the above steps and precautions, you can easily use the automatic spring roll mechanism to make delicious spring rolls.

Which flour is best for spring roll ?

Spring roll wrapper is super thin in thickness, smooth in surface, and egg-less wrapper. And Ingredients are wheat flour or rice flour, salt, and water.

The Low-gluten flour is referred to use in automatic spring roll wrapper forming machine. Low-gluten wheat flour refers to wheat flour with a moisture content of 13.8% and a crude protein content of less than 9.5%.

Tegishli mashinalar

Vegetable washing machine, potato peeling machine, vegetable chopping machine, meat grinder. Continuous fryer, freezing tunnel, screw type air compressor.