Lumpia Shanghai Maker DT-SR8000 Automatic Egg Roll Machine 7000 pieces to 8000 bir soat

Lumpia Shanghai maker is a technological marvel that automates the production from pastry sheet formation to stuffing filling, folding and rolling.

Egg Roll Machine DT-SR8000 is able to make vegetable spring rolls, lumpia, cocktail spring rolls, chicken spring rolls, beef spring roll, shrimp spring rolls, fresh spring rolls, spring roll frozen,fried rolls etc

Sig'im: 7000 uchun 8000 bir soat

Material: Oziq-ovqat darajasi zanglamaydigan po'lat 304.

Isitish usuli: Electric heating 380V 50HZ 3ph, transformer is needed for different voltage.

Lumpia Shanghai Maker Automatic Egg Roll Machine Application

What is a lumpia, shanghai spring roll and egg roll?

A spring roll is a thin pastry wrapper filled with various ingredients such as vegetables, meat, or seafood, bean paste etc, then folded and rolled. Spring rolls are either fried or baked until crispy.

Originating in China, spring rolls have evolved and are now popular worldwide, with variations like egg rolls and lumpia. Lumpia is Filipino version of spring rolls, but the flour based pastry is thin and delicate. Vaqt, egg roll is American version of Chinese spring rolls, with thicker wrappers made from wheat flour and egg.They are often served as appetizers or snacks, pairing perfectly with dips and sauces.

These delicate, fried or baked lumpia / bahor rulosi / egg rolls are a staple in many restaurants and homes. And traditional method by hand is labor-intensive and time-consuming. Biroq, our automatic spring roll / lumpia / egg roll production line simulates tradtional handmade method and automate the process with perfect products. Bundan tashqari, the adjustable wrapper thickness and stuffings filling system suitable for variety of stuffings materials enable our automatic spring roll line to be customized for spring rolls, or lumpia, or egg rolls.

Who will be needing the automatic Lumpia production line?

Lumpia Shanghai Maker is versatile and find applications in various settings:

- Food Manufacturing Plants: Perfect for large-scale production, spring roll making machine can churn out 2000 uchun 9000 pieces of spring rolls per hour, meeting the demands of food manufacturers.

- Restaurants and Food Service Providers: For eateries looking to offer fresh, homemade spring rolls without the labor cost, spring roll machines are an ideal solution. They ensure consistent quality and reduce preparation time.

- Central Kitchen: Our Model DT-SR2000, output 1500 uchun 2000 pcs /h and DT-SR4000, 3500 to 4000pcs/h is suitable for central kitchen where there will be large amount of food produced and safty needs guaranteed.

Lumpia Shanghai Making Machine Introduction

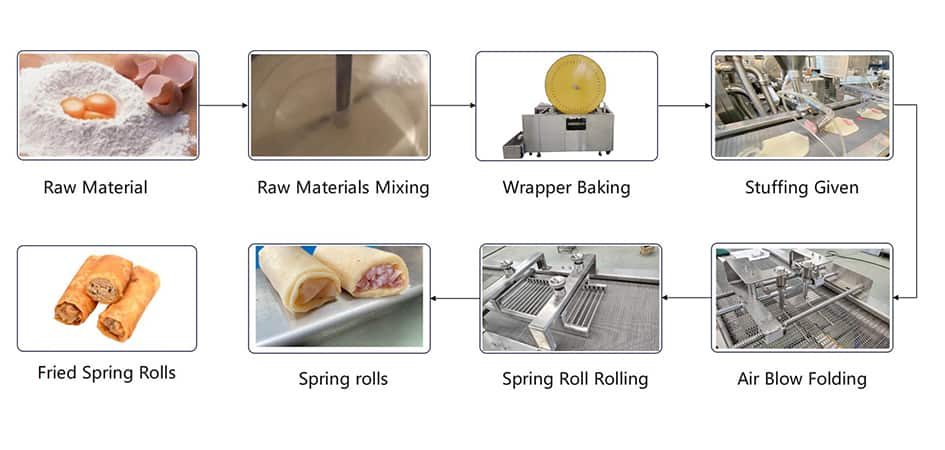

Lumpia Machine( Lumpia Rolling Machine) automates the process from lumpia wrapper baking, stuffings giving, wrapper folding and rolling. Shu sababli, the automatic lumpia making machine leverages advanced engineering to replicate the manual process with precision and speed, transforming a labor-intensive task into a streamlined, industrial-scale operation.

The fully automatic lumpia plant includes batter mixer, batter storage tank, lumpia wrapper machine, wrapper cooling fans, stuffing feeding system, air-blowing type folding system, and lumpia rolling machine. And we can also provide solution for raw material preparation (meat and vegetable processing), cooking solution and packing solution.

Even though, Lumpia automatic machine can customized for lumpia weight 15g to 100g. Bundan tashqari, it also customize for varioius sizes, for example the mini spring rolls dia. 2cm and length 5cm, and large spring rolls dia. 5cm and length 20cm. Other weight and size can be customized. Biroq, one production line is normally customized for one size and one weight of spring rolls / lumpia to keep end product uniform and consistancy.

Mini Lumpia Production Line DT-SR8000 Processing Flow Chart

Filipino Lumpia Machine including batter mixer 100L, lumpia wrapper baking machine, stuffing given devices, air blowing type folding devices, Lumpia rolling machine devices.

- Batter Mixer / Batter beater: 100L volume

- Wrapper Baking System: Includes batter storage tank, batter feeding and wrapper molding, and rotating baking Reel. The wrapper is customized and adnormal shape. Bundan tashqari, thickness of wrapper is adjustable to meet desired weight of wrapper.

- Stuffing Given part: Our advantage is to realize vegetable stuffings, meat stuffings and mixture of meat and vegetable stuffings together in one production line, by changing the stuffing mold. Ko'proq narsa, the stuffing amount is adjustable to get perfect ratio of pastry and stuffings.

- Air blowing folding devices: It decides the length of lumpia, so it is adjustable too so as meet length of spring rolls.

- Spring Roll Rolling Devices: There are wheels on this part to adjust diameter of Philipino lumpia

There is control box and PLC control pannel to set baking time, speed, stuffing amount automatically. Shunday qilib, normally, we customize the production line at factory to based on customer recipe, lumpia weight and size. All these data set and programmed in computer so that customer can open the production and run the line easily.

Shanghai Spring Roll Machine DT-SR8000 Specification

Machine Name and Model: DT Lumpia Machine / Fully Automatic Lumpia Production Line DT-SR8000

Sig'im: 7000pcs to 8000pcs an hour (taken 35to 40g spring roll size dia. 2.6sm, length 9cm)

Materiallar: Food grade stainless steel materials 304.

Water Proof grade: IPX5 (except baking part)

Isitish usuli: Elektr isitish

Kuchlanishi: 380V 50HZ 3ph. different voltage needs transformer.

Wrapper Shape: Abnormal shape customized.

Spring Roll Weight: 15g to 100g, customizable.

Stuffing Materials: Needs paste type stuffings, such as bean paste stuffing, meat and vegetable stuffings, vegetable stuffings, cheese stuffings, chicken stuffings etc.

Remark: For vegetable stuffings, they needs to be dewatered vegetables to avoid water dripping during stuffing giving process which might leads to inaccuracy in lumpia weight.

Filipino Spring Roll Machine Parameter

Aralashtirish 100L

Kuchlanishi | Kuch | Mixing Speed | Sig'im |

380V 50HZ 3ph | 3kvant | Up to 2900r/min | 100L /Batch (15min) |

Lumpia Making Machines Lumpia Molder Model DT-SR8000

Kuchlanishi | Isitish quvvati | Pneumatic | Stable Capacity | O'lchov | Net Weight |

380V 50HZ 3ph | 100kvant | 0.6 to 0.8mpa | 7000 to 8000pcs/h | 9000*2000*2100mm | 3850kg |

Lumpia Shanghai Machine Maker Features

High-Efficiency Of Lumpia Shanghai Machine

Compared to traditional manual wrapping, automatic spring roll machines can produce a large number of spring roll wrappers in a short period of time, greatly improving production efficiency. This is undoubtedly a huge advantage for the catering industry and food processing industry.

Precise Control:

Modern automatic spring roll machines are equipped with advanced control systems(PLC control system) that can precisely control key parameters such as baking temperature and humidity, ensuring the stability of spring roll wrapper quality, stuffing amount to keep sure the end spring roll weight accurate and uniform shape. The precise control guarantees the taste and appearance of spring rolls but also reduces waste.

Diverse Design

DT automatic spring roll machines are customizable special specifications, to make mini spring rolls to giant spring rolls, and different stuffings like vegetables, meat, banana paste, and mixture of vegetable and meat etc. Bundan tashqari, we have developed models to cover different production ranging from 1000pcs to 2000pcs per hour, 3000 to 4000pcs per hour, 6000 to 7000pcs per hour, 8000 to 9000pcs per hour and higher.

Adjustable Settings

Adjustable settings is customized to meet different customer requirement on size of the spring rolls, the amount of filling, and even the tightness of the wrap, ensuring versatility and precision.

Gigiena va xavfsizlik

Spring roll machines are designed with hygiene in mind. The machine is designed and made with food grade 304 Zanglamaydigan po'latdan yasalgan materiallar, and waterproof grade IP5 allow water spray to clean the machine from all direction (except baking machine). Easy-to-clean surfaces and materials is to resist the growth of bacteria. Qo'shimcha, there are two worker needed to regularly feed batter and stuffings, adjust parameter and monitor the working process in this line. Oxir-oqibat, bu oziq-ovqat bilan inson aloqasini minimallashtiradi, ifloslanish xavfini kamaytirish.

Cost-Effectiveness

Investing in spring roll making machines will be paid back soon by its increased production efficiency, reduced labor costs, and minimized food waste

DT Lumpia Roller Maker Manufacturer

1. Consistency in Quality:spring roll making machines produces uniform and accurate size and weight of spring rolls.

2. Durable and Stable in working. It ensure the production capacity and less maintenance cost.

3. Guarantee in service: The machine enjoy 12 months quality guarantee. Bundan tashqari, we offer Installation Guide, service and whole life technical support, and whole life spare part supply.

4. More value to customer: DT Ovqat mashinalari to'liq ishlab chiqarish liniyasining to'liq eritmasini taklif etadi, Sizning oziq-ovqat mahsulotlarini ishga tushirish va muvaffaqiyat qozonish uchun sizga bahorgi rulon retseptlari.

Our spring roll production line is popular to use in Germany, Poland, United Kingdom, France, United States, Austrilia, Indonesia, Saudi Arabia, Mexico, Argentina etc. Bundan tashqari, the spring roll wrapper production line, lumpia wrapper machine and samosa sheet making machine is also very demanding in Thailand, Philippines, Indonesia, Italy etc.

Lumpia Rolling Machine for Sale

When it comes to automatic spring roll making machines, “DT Spring Roll Machine” is a well-known brand in the market, and the price of DT Spring Roll Machine is not fixed and is according to following factors.

Model va tikilgan komponentlar

Mijozlar biznesining imkoniyatlariga erishish uchun, we have different models with production ranged from 1000pcs an hour to 9000pcs an hour and higher. Va biz elektr va pnevmatik komponentlarga har bir oziq-ovqat mahsulotlarini qondirish uchun elektron va pnevmatik tarkibiy qismlarga bo'lgan talablarga rioya qilingan brendlarni elektr energiyasini qabul qilamiz. They affect the spring roll making machines price greatly.

Vazifalar va konfiguratsiya

Spring roll maker is required to meet each customer end product, in terms of spring roll size, weight and various stuffing materials requirement. For special size of spring roll, and stuffing materials, the spring roll machine function is required customized to meet these requirements. Additional customized cost is required. Bundan tashqari, due to customer factory site or kitchen space limit, we have to design the production line layout to meet same.

Shu sababli, when choosing DT Spring Roll Machine, you should consider the production capacity of your need, the stuffing materials and end product dimension and weight etc. and your factory voltage and space factors. Communicate with our technical specialist and get more consultancy now.

How to use automatic lumpia roller ?

The use of fully automatic Lumpia spring roll machine enable making spring roll simple and efficient. And user shall follow the user manual and operation book. Here is production process in spring roll making factory

Machine preparation

Place the Shanghai Lumpia making machine on stable and ground level floor, connected to stable power source. Run few trial tests on each function before officially starch production.

According to the instructions, the well mixed batter is added to batter tank, and preheat the the spring roll sheet making machine about 30 minutes, and the specific time may vary by model.

Food preparation

The freshness and hygiene of the ingredients greatly affect the quality and taste of spring rolls. Shu sababli, the ingredients must be carefully selected, vegetable washed, meat grinded. Vegetable stuffings needs to be dewatered and meat needs to be without fiber, this to ensure the consistent stuffings giving and accurate in end product weight.

Operation technique

When all is ready to go, all the operation shall follow the operation book and adopt preset parameter and settings.

With the above steps and precautions, you can easily use the automatic spring roll mechanism to make delicious spring rolls.

Which flour is best for spring roll ?

Spring roll wrapper is super thin in thickness, smooth in surface, and egg-less wrapper. And Ingredients are wheat flour or rice flour, salt, and water.

The Low-gluten flour is referred to use in automatic spring roll wrapper forming machine. Low-gluten wheat flour refers to wheat flour with a moisture content of 13.8% and a crude protein content of less than 9.5%.

Tegishli mashinalar

Automatic spring roll machine DT-SR2000, Lumpia wrapper machine, lumpia fryer.