Tovuq chiplari fritöz uchun uzluksiz fritöz

Uzluksiz qovurdoq Avtomatik va uzluksiz qovurish tizimi avtomatik tovuq nuggetlari ishlab chiqarish liniyasida ishlatiladigan, pellet qovurish chizig'i, Fransuz Fres ishlab chiqarish liniyasi, Avtomatik kartoshka chiplari ishlab chiqarish liniyasi, banan chiplari liniyasi va boshqalar.

Sig'im: 100kg / h 1500 kg / soat, va talab bo'yicha moslashtirilgan.

Isitish manbai: Elektr, Gaz / lpg gazi, Tanlash uchun dizel

Materiallar: Oziq-ovqat darajasi zanglamaydigan po'lat 304

Uzluksiz qovurilgan dastur

Uzluksiz qovurish - doimiy qovurilgan jarayonni amalga oshirish uchun to'liq avtomatik bo'shashtirish dastgohi, Neft haroratini boshqarish, Frening vaqt, Fridli oziq-ovqat va atıştırmalık avtomatik ravishda zaryadlash. Qovurilgan mashinada mehnat xarajatlarini sezilarli darajada tejaydi va butun ishlab chiqarish liniyasining samaradorligini oshiradi. Va ko'p afzalliklari tufayli, Avtomatik qovurish mashinasi oziq-ovqat mahsulotlari ishlab chiqarish liniyasi uchun eng afzal ko'rgan tanlovdir.

Avtomatik qovurishlar doimiy qovurilgan chiplar uchun ishlatiladi, yong'oq, fri kartoshkasi, sho'r, yerfıstığı, Qabul qilingan yong'oq, baliq terisi, cho'chqa terisi, O'lain chiplari, fri kartoshkasi, Kartoshka chiplari, tovuq nuggetlari, bahor rulosi, Pani Puri va boshqalar.

Bundan tashqari, Uzluksiz chuqur chuqur qovurilgan uskunalar oziq-ovqat mahsulotlarini ishlab chiqarish liniyasida muhim rol o'ynaydi, kabi Avtomatik muzlatilgan frantsuz qovurilgan ishlab chiqarish liniyasi, Tovuq nuggetlarni qayta ishlash liniyasi, burger qovurish chizig'i, banan chiplari ishlab chiqarish liniyasi, qovurilgan chiziq va hk.

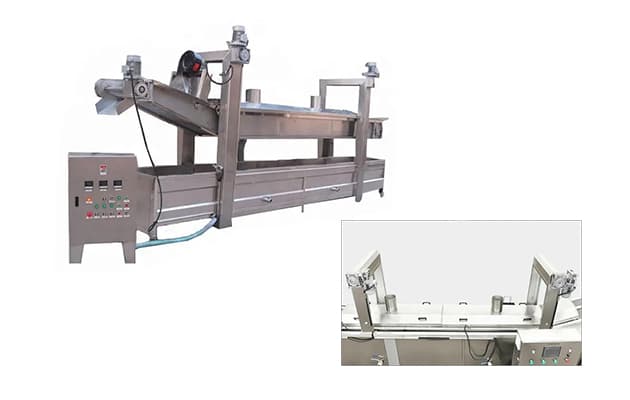

Doimiy qovurilgan mashinani kiritish

Avtomatik FRAER mashinasi tavsifi

Uzluksiz chuqur qovurilgan uskuna - bu doimiy qovurish tizimi, Kamarlarni bo'shatish vaqtini boshqarish uchun, Kamarni tozalash uchun bekor qilingan, Neft haroratini boshqarish va sozlash.

Va muzqaymoq mashinasi suzuvchi materiallarni yog 'bilan to'ldirish uchun ikki qatlamli kamar bilan qurilgan. Va kamarlar odatda qovurilgan materiallar asosida moslashtirilgan.

Bundan tashqari, Katta salohiyatli tashqi isitish, shuningdek, qoldiq va chiqindilarni axlatlash tizimi bilan dizayn, Neftni to'ldirish tizimi, yog 'filtrlash va zaxira tizimi va boshqalar.

Ko'proq narsa, Mezlantirish mashinasi nafaqat ustaxonalarda yoki markaziy oshxonada ham yolg'iz ishlatiladi, Ammo avtomatik oziq-ovqat mahsulotlarini ishlab chiqarish liniyasida doimiy ravishda ishlashda.

Uzluksiz sanoat fryer spetsifikatsiyasi

Isitish usuli: Elektr isitish / Gaz isitish / Dizel isitish

Mashinalar materiallari: Oziq-ovqat darajasi 304 Zanglamaydigan po'latli materiallar, eng yaxshi sifat

Haroratni boshqarish: Neft haroratini boshqarish tizimiga ega

Yog 'isitish harorati: 0℃ 300 ℃ dan (farangeyt 32 ° F ga qadar) 572.0 ° FIL

Sig'im: 100Kg / h 1500 kg / soat va moslashtirilgan sig'imga ega (Freyer mashinasozlik modellari va xom ashyolariga ko'ra)

Avtomatik qovurish mashinasi va ustunligi

Mini Freyer uzluksiz qovurish mashinasi

Mini donut mashinasi donutlarni qovurish uchun ishlatiladi, inqiroz, murosali, Chinchin pechene, bahor rulosi, samosa.

Tovuq nuggets mini qovurish mashinasi tovuq oyoqlarini qovurish uchun ishlatilishi mumkin, tovuq qanotlari, Sweet kartoshka chiplari minish vaqtining bir necha daqiqasi bilan.

Mini chiplar frantsuz qovurish uchun ishlatiladigan qovurilgan, Kartoshka chiplari, banan chiplari, yerfıstığılar.

Afzallik

Mini Freyersning afzalliklaridan biri bu qisqichbaqalar krakerini tayyorlash uchun sozlanishi mumkin, Makaroni kraker, Cho'chqa progi qavrilgan vaqt bilan kraker bir necha soniya ichida.

Bundan tashqari, Bu yangi boshlang'ich biznes yoki kichik va o'rta o'lchovli oziq-ovqat mahsulotlari uchun iqtisodiy va doimiy tanlovdir.

Uzluksiz qovurilgan mashina elektr isitish qovurilgan

Avtomatik elektr moyi qovuruvchi tovuq nuggetlari uchun mos keladi, burger qovurish, köfte, pishloq itlar, yerfıstığı, CHEMNI QABUL QILING, bahor rulosi, samosa.

Afzallik

Ishlab chiqarilgandan keyin tozalash osonroq.

Va isitgichlar yoqadi, Energiyani tejash va yog 'tezda isitiladi.

Yuqori rang va yuqori sifatli mahsulotlarni yaxshiroq va yuqori sifatli bo'lishiga ishonch hosil qiling.

Uzluksiz qovurilgan mashina issiqlik isitish freyeri

Gaz chiplari qovurilgan banan chiplari uchun mos keladi, O'lain chiplari, fri kartoshkasi, bahor rulosi, Kartoshka chiplari va boshqalar.

Afzallik

Gaz isitish doimiy qovurish mashinasi ba'zi mamlakatlarda energiya tejash va imtiyozli tanlov - bu elektr energiyasidan ancha arzonroq. Shu sababli, Ishlab chiqarish qiymati juda ko'p kamayadi.

Uzluksiz chiplar muzlatgich xususiyatlari va ustunligi

Ikki qavatli konveyer kamarini sozlash vaqti

Yuqori va pastki konveyer kamarlari qovurilgan taomni qovurilgan mashinadan qutultirish mashinasi chiqishiga olib keladi. Shu sababli, Qo'riqlash vaqti konvertatsiya tezligini o'rnatish orqali sozlanishi.

Skrapper bilan yuqori kamarni suzuvchi materiallarni yog 'bilan butunlay bosishi va uni oldinga siljitishi mumkin edi. Natijada, qovurilgan oziq-ovqat ranglari hatto va sifat yaxshi.

Avtomatik freyer mashinasida konveyer kamarlari moslashtirilgan va ishlab chiqarish ehtiyojiga qarab almashtirish mumkin. Masalan, Bizda Mesh kamarlari bilan qurilgan, zanjirli kamarlar, zanglamaydigan po'latdan yasalgan plastmasıl sim simeveyors va boshqalar. Xom ashyo xususiyatlariga ko'ra.

Avtomatik ko'tarish tizimini oson tozalash

Uzluksiz chuqur muzlatgich avtomatik ko'tarish tizimi bilan qurilgan. Yuqori qopqoqni ko'tarish va ishlab chiqarishdan keyin konveyer kamarlarini ko'tarish. Bu tozalash va yurishni davom ettirish ishlarini osonroq va qulay qiladi.

Neft filtrlash tizimi (Ixtiyoriy) Yog 'sifatini yaxshilang

Ba'zi bir vaziyatda xom ashyo tovuq nuggetlari, Baliq nuggets, Yonlangan bahor rulosi va boshqalar, yirtqichlar yoki chiqindilarni qovurish jarayonida yog 'ichida ketishi mumkin. Keyin yog 'filtrlash tizimi, ishlab chiqarilgandan keyin moyni onlayn filtrlash yoki yog' filtrini boshlashga majburdir..

Plannal chiplarini qovurish uchun kattaroq ishlab chiqarish liniyasida, yerfıstığı, Kartoshka chiplari, fri kartoshkasi, va hokazo, Neft filtri tizimi moy sifatini juda yaxshilaydi.

O'z-o'zini tozalaydigan tizim (Ixtiyoriy) Mahsulot sifatini yaxshilash

Mahsulot sifatini yaxshilash uchun, O'z-o'zini tozalaydigan tizim - bu variant. Ishlab chiqarish paytida u chiqindilarni pastdan pastga tushiradi. Bu neftdan foydalanish hayotini uzaytirishi va qovurilgan mahsulot sifatiga ishonch hosil qilishi mumkin.

Avtomatik chiplar Fryer mashinasi parametrini

Elektrni isitish doimiy qovurish mashinasi

| Model | Sig'im (Xom ashyo) | Kuch | Og'irligi | Freyer hajmi | Yog 'harorati |

| DT-CF-3500E | 500kg / h | 80kvant | 1000kg | 3500*1200*2400mm | 0-300 ℃ (32 ° F dan to gacha 572.0 ° FIL |

| DT-CF4000E | 600kg / h | 100kvant | 1200kg | 4000*1200*2400mm | 0-300 ℃ (32 ° F dan to gacha 572.0 ° FIL |

| DT-CF-5000E | 800kg / h | 120kvant | 1500kg | 5000*1200*2400mm | 0-300 ℃ (32 ° F dan to gacha 572.0 ° FIL |

| DT-CF-6000E | 1000kg / h | 180kvant | 1800kg | 6000*1200*2400mm | 0-300 ℃ (32 ° F dan to gacha 572.0 ° FIL |

| DT-CF-8000E | 1500kg / h | 200kvant | 2000kg | 8000*1200*2600mm | 0-300 ℃ (32 ° F dan to gacha 572.0 ° FIL |

| Izoh: Har bir model uchun yakuniy imkoniyatlar qovurilgan materialga ko'ra va uning kerakli qovurilgan vaqtga muvofiq o'zgaradi. | |||||

Gaz isitish doimiy qovurilgan mashina

| Model | Sig'im (Xom ashyo) | Quvvat iste'moli | Mashinaning og'irligi | Qovurish hajmi | Yog 'harorati |

| DT-CF-3500 | 500kg / h | 300,000 kkal | 1200kg | 3500*1200*2400mm | 0-300 ℃ (32 ° F dan to gacha 572.0 ° FIL |

| DT-CF-4000 | 600kg / h | 500,000 kkal | 1500kg | 4000*1200*2400mm | 0-300 ℃ (32 ° F dan to gacha 572.0 ° FIL |

| DT-CF-5000 | 800kg / h | 500,000 kkal | 1700kg | 5000*1200*2400mm | 0-300 ℃ (32 ° F dan to gacha 572.0 ° FIL |

| Har bir model uchun FINA sig'imi qovurilgan materialga va uning talab qilinishi kerak bo'lgan vaqtga qarab o'zgaradi. | |||||

Chiplar - sotiladigan doimiy kartoshka qovurilgan mashinasi

Chiplar Freyer yolg'iz ishlatishi mumkin, Ammo chip sicer bilan ham foydalanishingiz mumkin, deholing mashinasi, Uzluksiz kartoshka chiplarini ishlab chiqarish liniyasini tayyorlash uchun sovutish dastgohi va ziravorlar mashinasi, banan chiplari ishlab chiqarish liniyasi va boshqalar.

Biz ishlab chiqarish liniyasini eritmani sozlashimiz va biznes sig'imingiz va zavod bo'shlig'ingiz asosida mos mashinalarni tavsiya etishimiz mumkin. Batafsil iqtibos olish uchun hozir jamoamiz bilan bog'lanish uchun xush kelibsiz.

Uzluksiz chiplarni freyer mashinasidan foydalanish?

Sanoatning qovurilgan mashinasi o'rnatilgan va tekshirilgandan keyin, tozalamoq, zavodda sinovdan o'tkazildi. Foydalanuvchi o'z rejasi asosida ishlab chiqarishni boshlashi mumkin.

Biroq, O'rnatishdan keyin foydalanuvchi uchun qisqacha ishlash jarayoni.

- Suvni tozalang, Qovurish go'shti va konveyer kamari, va namlikni artib oling.

- Yog 'to'g'ridan-to'g'ri qovurilgan tomondan, yoki neftni saqlash idishini qovurish uchun qovurish uchun qovuring.

- Freyerni yoqing va neft haroratini o'rnating va isitishni boshlang.

- Mahsulotlar uchun eng mos vaqtni topish uchun konveyerning mos tezligini o'zgartirish uchun konveyerni yoqing.

- Ishlab chiqarish paytida neftni to'ldirish uchun, moyni qo'lda to'ldirishi mumkin / Yuvish balandligini yog 'sathidan neftni saqlash uchun idishdan to'ldiring.

- Ishlab chiqarilgandan keyin, Yog 'haroratini 60 ° dan pastga tushiring va neftni saqlash idishga soling, Yoki neftni saqlash idishga o'tishdan oldin neftni filtrlang.

Uzluksiz qovuruvchi ishlab chiqaruvchi

Kafolat

12 Oyliklarning sifat kafolati

Tarmoq narxida ehtiyot qismlar xizmatlari

Xizmat

Ishlatgandan so'ng operatsiyadan keyin, parvarishlash.

Zavodda liniya yoki o'chirish bo'yicha bepul mashg'ulotlar

Mijozning zavodida onzit o'rnatish

Umumiy biznes Yangi biznesni rejalashtiruvchini rejalashtirdi.

Xaridor mamlakatiga etkazib berish xizmatlari

Tegishli baliq va chiplar qovurilgan

Chuqur qovurilgan savati, kartoshka chiplari ishlab chiqarish liniyasi, yerfıstığı, Chinchin ishlab chiqarish liniyasi