Commercial Chin Chin Production Chin Chin Cutter 100KG per Hour

Commercial chin chin production line makes high-quality and delicious chinchin in a streamlined way.

Chinchin making machines includes chinchin mixer, dough sheet machine, industrial chin chin cutter, chin chin frying machine, chin chin packaging machin etc.

Material: Food Grade Stainless Steel 304

Kuchlanishi: 220V /380V 50HZ and customized voltage

Sig'im: 100kg per hour, 150kg per hour, upto 200kg/h

Commercial Chin Chin Production Line Application

Chin chin is a crunchy, golden brown Nigerian snack and enjoyed by people around the world. It is fried dough biscuit which served with original taste or with various spices and flavors. And with the growing demand for culturally diverse food options, chinchin presents a lucrative opportunity for food manufacturers.And our chin chin production line allows food manufacturers with efficient and reliable equipment to ensure high-quality output.

Chin Chin Production Introduction

Chin Chin Making Machine Description

For making chinchin, we have automatic production line for making chinchin with output 200KG an hour, suitable for food factory who persuit on larger capacity to expand market. Biroq, we also have semi-automatic chinchin making machines to help home made business into workshop with higher capacity.

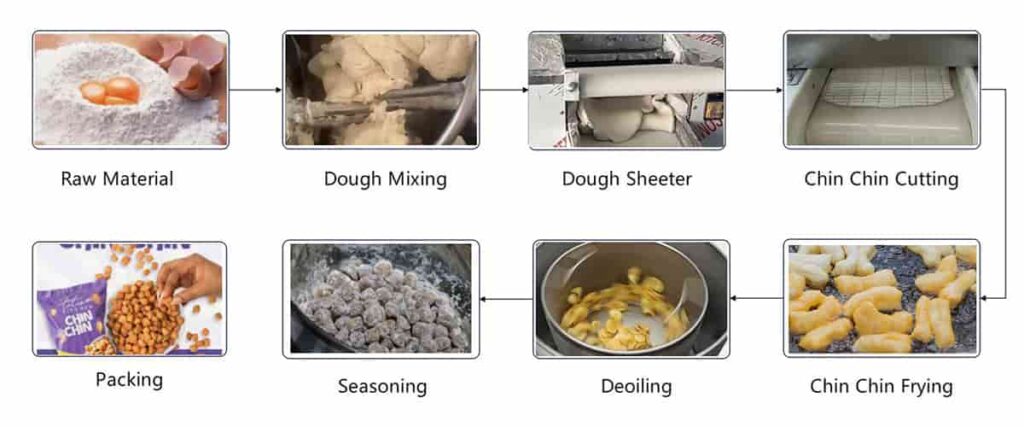

Chinchin production line is designed according to chin chin processing flow. The equipment for chinchin making are chin chin mixer machine, sheeting machine for dough, chinchin cutter machine, chin chin frying machine, snack seasoning machine, chin chin packaging machine.

Chin Chin Making Machines Specification

Isitish usuli: Elektr isitish / Gaz isitish

Mashinalar materiallari: Oziq-ovqat darajasi 304 Zanglamaydigan po'latli materiallar, eng yaxshi sifat

Sig'im: 50kg per hour to 200kg per hour, customizable

Chinchin Shape: Cube, strip, triangle, diamond, square etc customized.

Chin Chin size: customized to meet customer product

Package: plastic pack, bottle, box etc.

Factory space requirement: We can customized the production line based on the factory size and floor plan

Chin Chin Production Line Chart

Equipment for Chin Chin Making Advantage

- Efficiency: Chinchin dough mixer can handle large batch of dough mixing in minutes, and chin chin cutting machine could cut various shapes by changing the cutter. These automated chin chin making machine cut down production time and save a huge labor cost.

- Consistency: Industrial cutting machine ensure that the chin chin is cut into uniform shapes and sizes, resulting in a more consistent appearance and texture.

- Sifat: Automated chin chin making machines reduce the risk of human error, leading to higher-quality output. The consistent oil temperature control in the chin chin fryer also ensures that the chin chin is evenly cooked and not burnt. And it greatly increase the oil usage by advanced heating system.

- Tarqalish qobiliyati: With industrial chinchin cutting machine, it is easy to make varioius chin chin shapes and size in one machine by changing cutters. Bundan tashqari, the chin chin frying line makes it possible to make banana chips by adding a banana slicer. This is important for food manufacturer to expand their products.

Chin Chin Machine Features

Chin Chin Mixer

Dough Sheet Making Machine

Chin chin dough mixer is stainless 304 steel materials.

Commercial dough mixer, past shovqin, high volume, mixing evenly

Dough sheet machine allow dough feed in from lower belt to press, and coming out from upper belt to repeat pressing process.

Double chain drive, long use life.

Electric Chin Chin Cutter

Chin chin Frying Machine Deep Fryer

Chin chin machine cutter is customized for chin chin size and shape, like cube, strip, star etc.

Capacity 150kg/h

Basket type frying machine , suitable for use in commercial chin chin production line.

Frying time and temperature is controllable and adjustable. There are electric deep fryer and gas fryer for customer to choose.

Centrifugal Deoiling Machine (Optional)

Chin Chin Packaging Machine

This deoiling machine is centrifugal spinning to remove oil on chinchin biscuit after frying. Shu sababli, the chin chin is not oily and better taste and have long shelf life.

Chin chin packing machine has filling machine, bag making and sealing machine. Suitable for most size and shape of chinchin. Biroq, worker needs to weigh chinchin first before load each batch to bukets on this packing machine.

Semi-automatic Chin Chin Production Line Parameter

As professional chin chin making machine manufacturers, we customize our chin chin production line to meet business size. Here is chin chin production line data for reference only.

| Model | DT-100 | DT-150 | DT-200 |

| Sig'im | 50kg to 100kg per hour | 100kg to 150kg per hour | 150kg to 200kg per hour |

| Kuchlanishi | 380V 50HZ 3ph, customizable | 380V 50HZ 3ph, customizable | 380V 50HZ 3ph, customizable |

| Package type | In plastic bag, in jars, in bottles etc. | ||

Chin Chin Production Line Factory

Afzallik

Oziq-ovqat texnikasi zavodi

30 yillar r&D tarixi

Barqaror mashinasozlik ishi

Vaqtni etkazib berish bo'yicha

Kafolat

12 Oyliklarning sifat kafolati

Butun hayotni texnik qo'llab-quvvatlash va ehtiyot qismlar xizmati

Xizmat

Ishlatgandan so'ng operatsiyadan keyin, parvarishlash.

Zavodda liniya yoki o'chirish bo'yicha bepul mashg'ulotlar

Mijozning zavodida onzit o'rnatish

Umumiy biznes Yangi biznesni rejalashtiruvchini rejalashtirdi.

Xaridor mamlakatiga etkazib berish xizmatlari

Chin Chin Cutter Machine Price

We offer competitive pricing for our commercial chin chin production, with options to customize the machinery to your specific needs. Contact us today for a detailed quote and to learn more about our products and services.

Tegishli mashinalar

Automatic french fries production line, mini potato chips plant, banana chips production line, penauts frying line. continuous fryer, basket type deep fryer, round pot automatic fryer, continuous frying machine.