In the ever-evolving world of food and snack production, efficiency and quality are paramount. For those who need to reduce labor from their manual production of spring rolls or who plan to start production of spring rolls in large amount, the right equipment can make all the difference. This is where an automatic spring roll machine comes in. DT food machine factory offer various models of spring roll machines, with output ranging from 2000 pieces an hour to 9000 pieces an hour. While, how do you choose the best spring roll machine for sale? Together, we’ll delve into the world of spring roll production lines, and everything you need to know to make an informed decision.

Understanding Spring Roll Machines

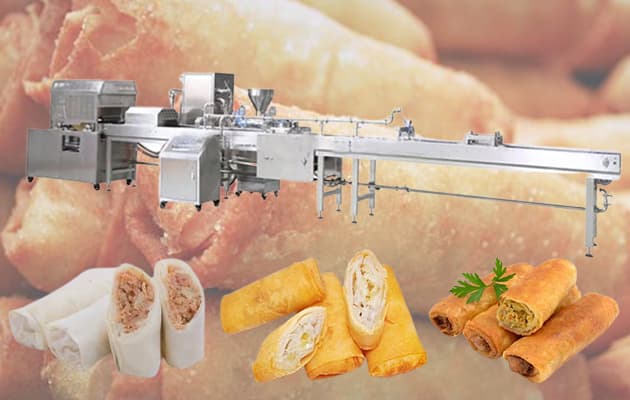

Before we look into the specifics of different machines, it’s essential to understand what a spring roll machine is and what it does. A spring roll machine is a piece of food processing equipment designed to automate the production of spring rolls. These machines can vary greatly in terms of features, capacity, and price, but they all share the common goal of streamlining the spring roll-making process.

The fully automated spring roll production line consists of spring roll wrapper making machine, stuffing hopper and filling divices, spring roll folding machine and rolling machine. The whole process is automatic control and all process action is programmed in PLC operation panel.

Besides, the spring roll machine have the stuffing hopper suitable for various stuffings. No matter it is vegan stuffings, meat stuffings, vegetable and meat stuffings, potato paste stuffing, or shrimp stuffings, stuffings with flavors etc. And it give accurate amount of fillings to make final spring roll even and in uniform appearance. However, the stuffing materials is better not to exceed 2mm in diameter to have accurate amount of stuffings.

The spring roll have the folding devices which is air blowing folding method to decide the length of spring rolls. And diameter of spring roll is adjusted and decided by rolling devices. However, these data is tested and set in factory according to client spring roll weight and size before handling to customer.

The Importance of Spring Roll Production Lines

So with this automatic spring roll making machine, customer only needs to fill the batter paste and stuffing materials regularly. And the automated spring roll machine guarantees accurate weight and dimension of spring rolls. In a word, Spring roll production lines not only increases your output but also ensures that each spring roll meets your quality standards

Types of Spring Roll Machines for Sale

When it comes to spring roll machines, there are several models to choose from, each designed for different needs and budgets. Here are some of the most popular options:

- Spring Roll Machine DT-SR2000 : The machine is suitable for making spring rolls 15g to 100g. The output ranges from 1500 pieces to 2000 pieces an hour. They’re ideal for small-scale production or startups with limited budgets. Such as restaurants and central kitchens.

- Automatic Spring Roll making Machine DT-SR4000: The automatic spring roll production can produce spring roll about 3500 pieces an hour to 4000 pieces an hour, taking 35g spring roll 2.6cm diameter 9cm for example. It is popular to use for new food factory, central kitchens who seek high output and quality products.

- Automatic spring roll making machine DT-SR8000: Fully automated spring roll line with output 7000 pieces to 8000 pieces an hour. And it is perfect for large-scale production and businesses looking to maximize efficiency.

Spring Roll Machine Specification

Capacity: 2000pcs to 9000pcs an hour (taken 30g to 40g spring roll size dia. 2.6cm, length 9cm)

Materials: Food grade stainless steel materials 304.

Water Proof grade: IPX5 (except baking part)

Heating Method: Electric heating

Voltage: 380V 50HZ 3ph. different voltage needs transformer.

Wrapper Shape: Abnormal shape customized.

Spring Roll Weight: 15g to 100g, customizable.

Stuffing Materials: Needs paste type stuffings, such as bean paste stuffing, meat and vegetable stuffings, vegetable stuffings, cheese stuffings, chicken stuffings etc.

Remark: For vegetable stuffings, they needs to be dewatered vegetables to avoid water dripping during stuffing giving process which might leads to inaccuracy in spring roll weight.

Spring Roll Production Line Supplier Parameter

| Model | DT-SR3000 | DT-SR4000 | DT-SR8000 |

| Voltage | 380V50hz 3ph | 380V50hz 3ph | 380V50hz 3ph |

| Elcctric heat power | 40kw | 60kw | 100kw |

| Air source pressure | 0.6-0.8mpa | 0.6-0.8mpa | 0.6-0.8mpa |

| Productivity | 1500-2000pcs/h | 3500-4000pcs/h | 7000-8000pcs/h |

| Net Weight | 1520kg | 2860kg | 3580kg |

| Size | 7.5M*1.2M*2.0M | 9.0M*1.4M*2.0M | 9.0M*2.0M*2.1M |

Spring Roll Production Solutions: From Start to Finish

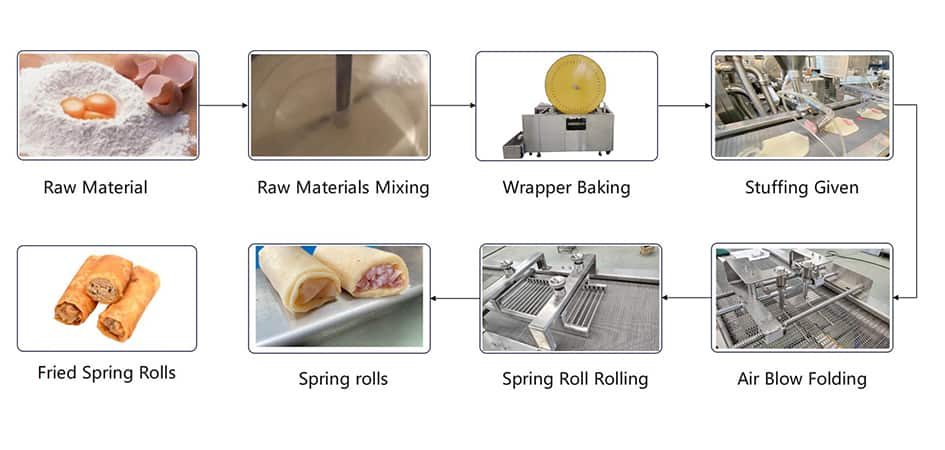

Now that you have a better understanding of the different types of spring roll machines available, let’s take a closer look at the entire production process and how machines can streamline it.

- Preparation of Ingredients: The first step in spring roll production is preparing the ingredients. This includes chopping vegetables, cooking meat or seafood, and preparing any sauces or fillings. While this step typically requires manual labor, having the right tools, such as vegetable chopping machine, meat grinder and mixers, can make it more efficient.

- Forming the Wrappers: Spring roll wrappers are thin sheets of dough made from flour and water. Machines can automatically bake and mold the adnormal spring roll wrappers. Thickness of pastry can be customized, minimum thickness 0.2mm.

- Filling and Sealing: Once the wrappers and fillings are ready, the next step is to fill and seal the spring rolls. Machines can do this quickly and accurately, ensuring that each spring roll has the perfect amount of filling and is properly sealed to prevent leakage.

- Cooking: Depending on your preference, spring rolls can be fried. Our deep fryers, can automate the cooking process.

- Packaging and Labeling: Once the spring rolls are cooked, they need to be packaged and labeled for sale. Automated packaging machines can handle this step, ensuring that each package is properly sealed and labeled with all necessary information.

Production Flow of Spring Roll Production Line

Spring Roll Machine Manufacturer

Investing in a spring roll machine is a smart move for any business looking to streamline its production process and increase efficiency. With the right machine, you can produce high-quality spring rolls quickly and consistently, giving you a competitive edge in the market.

Spring Roll Production Line Factory Advantage

- One-stop food machinery factory

- 30 years R&D history

- Stable machinery performance

- On time Delivery

Guanratee

- 12 Months Quality Guarantee

- Whole life technical support and spare part service

Service

- After-sale support in operation, maintenance.

- Free Training on line or off line at factory

- Onsite installation in Customer’s factory

- Overall business advises for new business planner.

- Delivery services to buyer’s country

Remember, the key to successful spring roll production is not just having the right equipment but also using it effectively. With the right machine and the right spring roll machine supplier, you can create delicious, high-quality spring rolls that will keep your customers coming back for more. So, what are you waiting for? Start exploring your options today and take the first step towards a more efficient and profitable spring roll production process.