Макароны линия макароны производителя спагетти

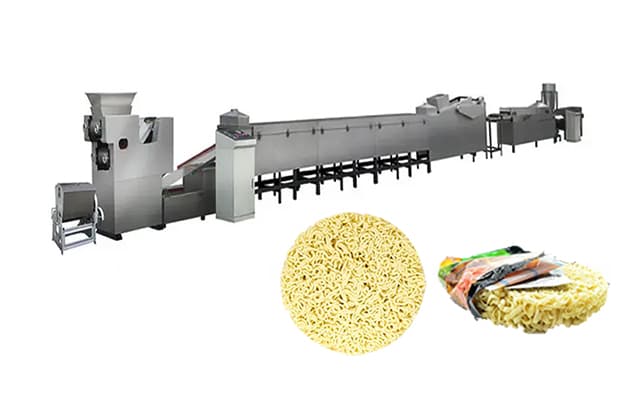

Макароны линия Идеально подходит для производства различных типов пасты с короткой обрезанием, в том числе макароны, Пенн, Фусилли, и больше. Весь набор Включает в себя смеситель теста, Эквердирующая машина, резак, переключатель, сушильная машина, охлаждающий конвейер и упаковочный аппарат.

Сырье: картофельный крахмал, кукурузный крахмал, крахмал маниоки, пшеничная мука, кукурузная мука и т. Д. В качестве сырья.

Емкость: 100 к 120 кг/ч & 250-300 кг/ч

Макароны макароны производственной линии

Линия макаронов идеально подходит для производства различных типов макароны с короткой обрезанием, в том числе макароны, Пенн, Фусилли, и более. И это подходит как для свежей, так и для сухой производства пасты. Изменяя различные формы, он также может сделать сценарий оболочки, Orecchiette, Тремелла хрустящая, Пятизвездочный хрустящий, рисовая кора, Фонари , раковина, Тип арахиса, большие и маленькие пустые трубки разных форм.

Кроме, Эта линия может быть настроена для удовлетворения конкретных производственных требований и потребностей в мощности. И с его передовыми технологиями и производственным процессом, это обеспечивает последовательное качество пасты, форма, и текстура.

Макароны производитель введения

Описание макаронов

Макароническая лапша макароны - это любимая традиционная итальянская кухня, которая была основной едой, которую наслаждается во всем мире. DT FOOD MACHINE, ведущий поставщик решений для производства пасты, предлагает всеобъемлющий Производственные линии пасты, Пользователи для широкого диапазона макаронов макароны формы и размеры. И наша производственная линия макаронов предназначена для удовлетворения требований как мелких, так и крупномасштабных производителей макаронных изделий, Обеспечение высококачественного производства с минимальными усилиями и низкой стоимостью производства.

Макароны изготовление макароны спецификации машины

Метод нагрева: Электрическое отопление

Машинные материалы: Материалы из нержавеющей стали

Емкость: 100 к 120 кг/ч & 250-300 кг/ч

Напряжение: 380V 50 Гц 3PH, Доступно индивидуальное напряжение.

Блок -схема производственной линии макаронов

Полный поток производства на производственной линии макаронов - от смешивания до экструзии, резка, сушка, охлаждение, и упаковка. Автоматическая линия макаронов обеспечивает плавный производственный процесс, Минимизация отходов и максимизация выхода.

Макароны макаронные машины

Рациональный дизайн и высокая автоматизация

Производственная линия макаронов макаронов может похвастаться рациональным дизайном, который максимизирует эффективность и сводит к минимуму время простоя. Его высокая степень автоматизации допускает бесшовную работу, Сокращение потребности в ручном вмешательстве и повышение производительности.

Строительство нержавеющей стали

Основной корпус производственной линии построен из нержавеющей стали, обеспечение долговечности и простоты очистки. Этот материал устойчив к коррозии и поддерживает гигиенические стандарты, Решающий для среды производства продуктов питания.

Износостойкие винты

Винты, используемые на стадии экструзии, изготовлены из 38CRMNAL, материал, устойчивый.

Регулируемая температура и скорость вращения

Регулируемая температура и скорость вращения: Производственная линия имеет регулируемую температуру и настройки скорости вращения, позволяя вам точно настроить производственный процесс для достижения оптимального качества пасты.

Автоматическое макароны изготовления параметра

| Модель | Власть | Емкость | Размер линии |

| DT100 | 130кВт | 100-120кг/ч | 25*3*3м |

| DT250 | 230кВт | 250-300кг/ч | 35*4*4м |

1. Тесто миксер

Используется для смешивания ингредиентов.

Власть:4кВт

Измерение(м):1.1*0.8*1.2

2. Винт лифт

После смешивания пшеничной муки, лифт SCEW подает тесто в бункер на Extuder .

Власть:1.1кВт

Измерение(м):1.7*0.6*2.2

3. Экструдер

Он разместит лапшу макароны макароны.

Модель DT100

Общая мощность:95кВт

Измерение:3.2*0.9*1.9м

3. Резак

Когда тесто экструдируется в круглой трубе, Затем потяните круглую трубку в машину для формирования для охлаждения ,катание и разрезание в более короткие трубки.

Общая мощность:1.5кВт

Измерение(м):1.7*1*1.5

4. Вибрирующий переключатель

Вибрирующая машина отделяет лапшу с пасты перед сушкой.

Емкость: 3КВА

Измерение:1.5X 1 x 0,5 м

5. Сушильная печь

Сушка духовки для обезвоживания

Измерение: 3.5*1.1*2.1 & 5.4*1.3*1.8М

Власть: 43.5КВт

Сушильная печь для сушки

Измерение: 4.0*1.1*2.1м & 8.4*1.3*2.2м

Власть: 83.5 кВт

6. Охлаждающий конвейер

Охлаждающий конвейер охлаждает лапшу с макаронами перед упаковкой.

Измерение: 5.2*0.8*1.4м

Власть: 1кВт

7. Упаковочная машина

Автоматически упаковать макароны в полиэтиленовый пакет, Автоматическая упаковочная машина макароны - идеальный выбор. Это включает лифт, Многопользовательский весер, фиксированная форма, Устройства для изготовления мешков с функцией печати даты, и конвейер конечного продукта.

Модель упаковочной машины рекомендуется на основе размера упаковки и веса.

Макароны производителя производителя

Преимущество

DT Food Machine предлагает решение с ключом, включая установку оборудования, отладка, и обучение операторов. Наши инженеры посетят вашу фабрику, чтобы гарантировать, что производственная линия будет работать гладко, прежде чем передать ее своей команде.

Гарантия

12 Гарантия качества на месяц

Вся пожизненная техническая поддержка и обслуживание запасных частей

Услуга

Послепродажная поддержка в работе, обслуживание.

Бесплатное обучение онлайн или офлайн на заводе

Установка на месте на заводе Заказчика

Общие бизнес-советы для нового бизнес-планировщика.

Услуги доставки в страну покупателя

Цена на создание макаронных изделий

Производственная линия DT Food Machine Pasta Macaroni предлагает комплексное решение для производителей макарон, стремящихся расширить свои производственные возможности. С его передовыми технологиями, Высокая автоматизация, и настраиваемые функции, Наши линии лапши пасты становятся краеугольным камнем производственных операций макаронных изделий.

Добро пожаловать, чтобы связаться с нашей командой для профессионального бизнес -предложения и производственного решения сейчас.

Сопутствующие машины

Мгновенная линия лапши, Создатель макаронных изделий, Наклейте с лапшой, тесто миксер, Автоматическая упаковочная машина для лапши.