Electric Ice Cream Cone Maker Commercial DT-24C Wafer Cone Machine for Sale

Electric ice cream cone maker commercial DT-24C is manual ice cream cone machine, with 24 выпечка, output 600 pieces to 800 штук в час. Advantage of this model is acceptable for customized different ice cream cone shapes and sizes, such as horn shape cone, torch cone, bowl cup cone, twin head wafer cone,пластинка, corn wafer cone etc.

Емкость:600 to 800pcs/h

Источник отопления: Electric heating 380V 50HZ 3ph and customized voltage

Материалы: Outer cover stainless steel / carbon steel

Electric Ice Cream Cone Maker Commercial DT-24C Application

Electric ice cream cone maker commercial DT-24C is an efficient baking tool for producing wafer cones. It ensures the high-quality final product that caters to the diverse tastes of consumers. Before, we get to know more about this wafer cone making machine DT-24C, let us know what is wafer cone.

Что такое конус пластины?

Конус мороженого-конус в стиле пластин, золотисто-коричневый, нейтральный со вкусом с свежей текстурой. Конусы пластин получают самое низкое содержание сахара. И они запекаются внутри формы в форме конуса, И нет шансов на протекание мороженого через дно.

Ice Cream Wafer Cone Making Machine

The commercial wafer cone machine is designed for use in a variety of settings, including restaurants, кафе, Пекарни, and ice cream parlors. Its electric heating system allows for the quick and even baking of ice cream cones, ensuring a consistent texture and flavor. Кроме, ice cream wafer cone machine can produce an array of cone shapes and sizes, catering to different customer preferences. Such as wafer cup, torch cone, horn shape wafer cone, double head torch cone, snail shape biscuit, peanut shape, fish-shaped cone etc.

Among all ice cream cone machine, commercial wafer cone machine DT-24C has 24 выпечка, (able to make 24 pieces of wafer cones per batch). And it produces wafer cones with output about 600 pieces to 800 штук в час. Кроме, it is one of most popular ice cream cone machine among ice cream cone distributors and even new business. Becauses the model DT-24C wafer cone machine is economical in cost, big output, and able to customized for various shape and size wafer cones.

Wafer Cone Machine Sale Specification

Имя: Electric Ice Cream Cone Maker Commercial

Модель: DT-WC24C

Емкость: 600 to 800pcs/h

Цена: Лучшая цена, прямые поставки с завода высочайшего качества

Источник отопления: Электрическое отопление

Скорость напряжения: Standard 380V 50HZ 3Phase. Дружеская записка: Изменение напряжения Индивидуальная стоимость рассчитывается отдельно как спрос клиента.

Материалы: Outer cover of machine is stainless steel material or carbon steel material with paints.

Настройка: The wafer cone machineWC-DT-24C is customized as per cone shapes and sizes. Однако, Каждый набор машины для выпечки конуса настроен только для одного размера и одной формы конусов

Ice Cream Cone Machine Maker Parameter

Data on ice cream cone machine

| Имя | soft serve ice cream cone machine / Electric Heating Wafer Cone Making Machine | |||||

| Модель | DT-WC4 | DT-WC10 | DT-WC24C/DT-24C) | DT-WC32C | DT-WC40 | DT-WC60 |

| Количество формы для выпечки | 4 | 10 | 24 | 24 | 40 | 60 |

| Емкость | 100 to 120pcs/h | 250 to 300pcs/h | 600 к 800 шт/ч | 600 к 800 шт/ч | 1200 к 1400 шт/ч | 2400 к 3000 шт/ч |

| Власть | 3.6кВт | 5кВт | 12кВт | 15кВт | 18кВт | 12кВт |

| Напряжение | 380V 50 Гц Трифа | |||||

| Dimension in mm | 530×430×700 | 760×600×1050 | 730×800×1370 | 880×880×1380 | 1080×890×1465 | 1120×11080×1550 |

| Вес нетто | 80КГ | 200КГ | 350КГ | 450КГ | 660КГ | 1050КГ |

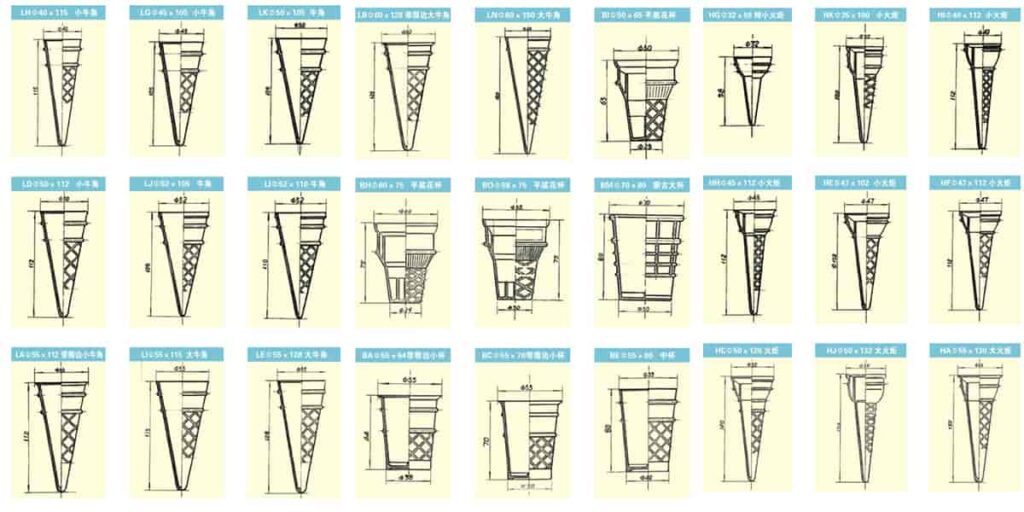

Ice Cream Cone Drawing for New Business Customer to Choose

Функция машины изготовления конуса пластин

Легкая установка и простой работа с меньшими затратами

В большинстве случаев, Мы упаковываем целую машину в одну упаковку. Поэтому, Чтобы установить электрическую машину мороженого мороженого, Вам понадобится человек с электрическим фоном или профессиональным инженером -электриком, чтобы подключить машину к основной мощности вашей мастерской или кухни и начните использовать машину.

Рабочий должен питать пасту с тестом для выпечки плесени вручную, Потяните ручку на машине, чтобы закрыть форму для выпечки. После окончания выпечки времени, Рабочий должен поднять формы для выпечки, чтобы позволить выбросу конусов снизу и начать производство следующей партии. Операция проста.

Пользователь должен следовать руководству по обслуживанию, чтобы позаботиться о машине после ежедневного производства. Однако, Легко носила запасная часть - это обогреватели, которые могут измениться после использования в течение почти года. Обычно мы поставляем добавочный запасной нагреватель с доставкой пластинного конуса и рекомендуем клиенту заказать больше с помощью машины в качестве запчастей.

Отдельное управление выпечкой на нижних форм для выпечки и верхних плесени

Существует отдельный контроль отопления для целого набора верхних форм для выпечки, а другой набор пекарских форм.. Пользователь должен установить температуру выпечки на основе нашего заводского пробного теста, однако, Они могут приспособиться в соответствии с их потребностями. Легко установить данные вручную.

Служба настройки

Конусы пластин имеют различные формы , Размер и дизайн логотипа с завода мороженого. Поэтому, DT Pafer Cone Machine необходимо настраивать формы для выпечки и ее способность удовлетворить спрос со стороны разных клиентов.

Дружеская записка, нашему пользователю важно общаться с нашей командой, поделиться дизайном конечного продукта, размер и форма для получения окончательного решения.

Кроме, Уровень промышленного напряжения не все в каждой стране. Так, Мы можем настроить машину для выпечки конуса на заводе перед доставкой клиенту.

Удобный

Создатель мороженого Cone очень дружелюбен к оператору, Особенно пользователь без технического и магонного опыта работы. Оператор обычно может работать более чем на одну машину за раз, так как им нужно только заполнить пасту для выпечки, Закройте формы для выпечки и открыть формы для выпеченных запеченных шишек.

Adantage of DT Cone Maker Machine Company

Над 30 Год пластины Производство и разработка

Десятилетия производства и модернизации конуса оборудования, так что у наших пользователей лучший опыт. От начальной полуавтоматической конусовой машины пластин, Он был обновлен до управляемой ПЛК автоматической ваферной конусной машины, и, наконец, на автоматическую туннельную конусную машину, используемую крупными заводами мороженого. Мы всегда стремились адаптировать наше оборудование для удовлетворения потребностей разных пользователей разных размеров бизнеса.

Качество и обслуживание guranteed

Качественное оборудование достижения доверия клиента, и качественный сервис позволяет клиентам стать партнерами. Каждый клиент очень ценен и импортирует для нас, и все ваши потребности в компании DT Food Machine будут слушать и оплачивать 100% усилия, чтобы встретиться.

Цель производства конусовых машин состоит не только в том, чтобы сделать удовлетворительные конусы, Но чтобы помочь потребностям каждого клиента, и его желания реализованы.

Поэтому, будь то новые клиенты или постоянные клиенты, Мы будем слушать клиентов’ бизнес -планы и трудности с производством, и дайте профессиональные советы и решения. В то же время, У нас есть профессиональная команда после продажи для отслеживания производства, доставка, установка, Использование клиентов и условия бизнеса и предоставление необходимой поддержки.

Больше пользы для клиента

Мы будем поддерживать вас из обмена информацией о тенденциях рынка мороженого, Выбор подходящего решения для вашего бизнеса мороженого, поставьте удовлетворительные конусы и помогите вам с установкой и разработкой рецептов. Мы прилагаем все усилия для вас, чтобы помочь вашему стартапу в пищевом бизнесе и добиться успеха.

Ice Cream Cone Machine Price in Uganda

Цена конуса варьируется из -за типа машины и диапазона модели модели. Пожалуйста, свяжитесь с нашей профессиональной поддержкой продаж, чтобы получить стандартную цену.

Однако, Для индивидуальной формы конуса мороженого, Дизайн логотипа и размеры не в нашем предыдущем производственном диапазоне, Нам нужно будет только добавить индивидуальную стоимость на машину.

Поговорите с нашей командой сейчас, чтобы поделиться большим количеством своего бизнес -плана и сделайте шаг вперед в пути сладкого и успеха.

Что такое ингредиент для изготовления пластин?

Базовый ингредиент конусного конуса, подходящий для машины для изготовления пластин, крахмал, пищевое масло, соль, и вода и т. д.. После заказа мы предоставим вам базовое соотношение рецептов, и вы можете добавить свои секретные ингредиенты, чтобы придать особый аромат и вкус..

How to make wafer cones ?

Electric ice cream cone maker commercial is ideal baking machine for making wafer cones. And here is basic process of using a commercial wafer cone making machine. Place the ice cream wafer cone machine on flat ground. Connec the machine to your factory main power.

- Следуйте ручной книге, чтобы дважды проверить каждую часть машины, чтобы убедиться, что они хорошо сборки.

- Очистите и предварительно разогреть машину. Пожалуйста, чистите жирное масло всем. И, пожалуйста, удалите отходы на выпечке. Дружелюбное напоминание,не разрешается использовать жесткий или острый нож для очистки формы для выпечки, Чтобы избежать повреждений при выпечке.

- Включите машину для выпечки. (Время выпечки и температура выпечки задаются перед доставкой., но его можно настроить на сайте пользователя в зависимости от потребностей его продукта..

- После производства, Окупить машину, и отключить электричество. Чистая выпекающая машина в соответствии с книгой пользователя.

Сопутствующие машины

Автоматическая линия по производству рожков мороженого, Автоматическая пластина, миксер для теста, ice cream machine DT-4