Frozen French Fries Machine Automatic French Fries Processing Plant

French fries production line is an automatic and advanced production solution on processing potato into french fries.

Automatic french fries processing plant contains potato washing and peeling machine, french fries cutter machine, машина для бланширования, обезвоживающая машина, french fries deep fryer machine, машина для обезжиривания, охлаждающая машина, quick freezer, automatic packing machine and its auxiliary equipments.

Applied to: Potato chips, Чипсы из сладкого картофеля, long plantain chips, картофель фри, fresh french fries, frozen french fries, plantain chips etc.

Емкость: 50-100кг/ч, 200-250кг/ч, 350-400кг/ч, 500кг/ч, 1000кг/ч, 1500кг/ч, 2000kg/h and customized capacity.

Frozen French Fries Production Line Application

Frozen french fries making machine is advanced solution for frozen french fries manufacturers. No watter it is automatic potato french fries machine production line for larger french fries factories, or small scale frozen french fries production line for medium size factory or new french fries factory. Our potato processing plants enable investors with good returns by greatly reducing labor, improving product quality, providing productivity and market share.

Frozen chips making machine is also popular among snack food manufacturers who want the line to make various chips, such as potato chips, чипсы из подорожника, sweet potato chips etc. And Because of the seasonality of raw materials, they need a production line for off-season production to produce other products.

Frozen Potato Production Line Introduction

Frozen French Fries Production Line Description

Commercial french fries machine is a complete production line covering raw material washing and peeling machine, машина для бланширования, potato cutter, french fries fryer, quick freezer, automatic weighing and bagging machine.

And we customize potato processing plant to meet different business sizes. Поэтому, we have semi automatic french fries production line for capacity 50kg per hour but also small scale french fries production line with output 100kg per hour, and fully automatic frozen french fries production line upto 2000kg per hour. Кроме, we customize the french fries making machine with the capacity needed by customer.

French Fries Production Line For Sale Specification

Метод нагрева: Электрическое отопление / Газовое отопление

Машинные материалы: Пищевой класс 304 материалы из нержавеющей стали, лучшее качество сделано

Температура нагрева масла: 0от ℃ до 300 ℃ (от 32°F по Фаренгейту до 572.0 °Ф )

Емкость: 50KG/H to 2000KG/H (более высокая емкость может быть настроена)

Требуемая производственная площадь: Мы можем настроить производственную линию в зависимости от размера завода и плана помещения..

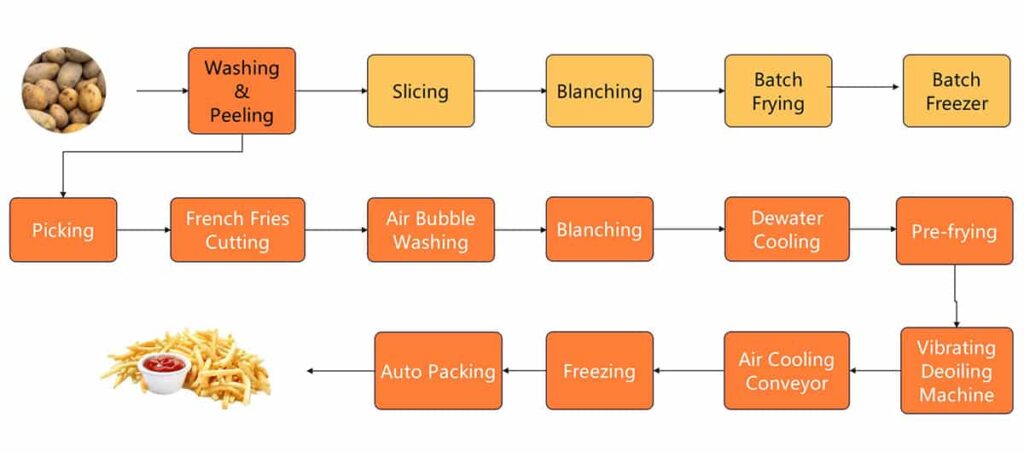

Fully Automatic French Fries Machine Flow Chart

It includes small scale french fries production line semi-automatic and fully automatic french fries production line processing flow.

French Fries Machine Features

Potato Peeling Machine

This is washing and peeling machine continuous стирка, peeling and discharging.

Because the uneven and corrugated brushes is composed of stiff bristle brush and emery brush which enable to peel the potatoes completely.

Кроме, the sprial type peeling machine push the potato foward and discharge from the other end to picking conveyor belts before slicing process.

Более того, it is suitable for washing and peeling potato, sweet potato, cassava, ginger, лук, carrots etc.

French Fry Potato Cutter Machine Electric

potato french fries cutting machine is commercal french fries cutter with high output. And french sticks size 7*7mm, 8*8мм, 10*10мм, and custom-made can be changed by adjusting the blade.

French fries cutter machine is also suitable for other root vegetables, like carrots, cassava, и т. д..

The end product is smooth, uniform and free of breaks.

Blanching Potatoes Before Frying

This is blanching machine to protect the french sticks color and remain goods taste.

Potato chips branching time is about 5 to15 minutes at hot water temperature 70℃ (158.0 °Ф). And the stainless steel mesh belt is with frequency conversion speed regulation, so the blanching time and speed is adjustable.

There are continuous branching machine with gas heating and continuous branching machine with electric heating for customer to choose.

Potato dewatering machine

Air cooling machine removes the water and cool down the temperature of branched potato sticks before frying. It shortens the frying time and ensure the quality taste of french fries.

And to have better effect, a vibrating deoiling macine is necessory to be used before air drying and dewatering conveyor belt.

french fries deep fryer machine

For small scale potato chips plant, the basket type deep fryer or round pot frying machine is ideal choice for capacity below 200kg an hour.

Однако, for fully automatic french fries production plant, the continuous frying machine is best option to keep the frying time continuous working with larger capacity and less labors. Best french fries machine is stainless steel materials and its frying time is adjustable and oil temperature adjustable.

Кроме, we can also customize the fryer to automate the process of oil refill, oil recycle, oil filtering and self cleaning system. This will greatly improve the production efficiency, prolong oil usage and bettter quality french fries.

Deoiling Machine

Vibrating Deoiling machine is neccessory to remove oil on surface of french fries after frying.

Because, the fried french sticks from frying line normally carry some oils which cause the product oily and may polute the production floor. Поэтому, the vibrating machine with oil receiving plates is good to deoiling the oil from chips surface and keep the production site clean.

Что еще, during vibrating process, the chips are moving foward and spread even to next process.

Охлаждающая машина

Cooling conveyor is installed with ventilators blowing wind to french fries. Therefore the surface temperature drop sharly by natural strong wind. This is important process before quick freezing process.

And oil receiving plate under the cooling conveyor is optional to receive oil dropped from french fries.

Fries Freezer Tunnel Freezers IQF Freezers

French fries quick freezer is applicable to freeze large quantities of french fries in short periods of time without causing any clumps from developing or having the product stick together.

Center temperature of material to feed:<20 С

Discharge temperature: -18℃

Freezing time: 15 min to 45minutes.

Packing Automatic Machine with Weighing, Filling and Bag Making

To pack frozen french fries into plastic bag automatically, the automatic pouch filling and sealing machine is ideal choice. It includes elevator, Многопользовательский весер, фиксированная форма, Устройства для изготовления мешков с функцией печати даты, и конвейер конечного продукта.

Что еще, the chips packing machine has advantage of high efficiency, accurate weighing, and working continuous with the french fries processing line.

French Fries Processing Line Parameter

Frozen French Fries Machine List as below for reference only. And we are able to customize the fries processing line based on customer factory layout, Напряжение, end product varieties, packing type etc.

| Нет. | Machine Name | Quantity | Unit | Скорость напряжения |

| 1 | Elevator | 1 | Set | 380V 50HZ 3ph Can be customized |

| 2 | Potato washing and peeling machine | 1 | Set | 380V 50HZ 3ph Can be customized |

| 3 | Select conveyor belt | 1 | Set | 380V 50HZ 3ph Can be customized |

| 4 | Potato cutter | 1 | Set | 380V 50HZ 3ph Can be customized |

| 5 | Bucket spray lift | 1 | Set | 380V 50HZ 3ph Can be customized |

| 6 | Unqualified French fry picking machine | 1 | Set | 380V 50HZ 3ph Can be customized |

| 7 | Rinse machine | 1 | Set | 380V 50HZ 3ph Can be customized |

| 8 | Blanching machine | 1 | Set | 380V 50HZ 3ph Can be customized |

| 9 | Vibration dehydrator | 1 | Set | 380V 50HZ 3ph Can be customized |

| 10 | Air-cooled dryer | 1 | Set | 380V 50HZ 3ph Can be customized |

| 11 | Elevator | 1 | Set | 380V 50HZ 3ph Can be customized |

| 12 | Continuous frying machine | 1 | Set | 380V 50HZ 3ph Can be customized |

| 13 | Vibrating deoilingg machine | 1 | Set | 380V 50HZ 3ph Can be customized |

| 14 | Air-cooled dryer | 1 | Set | 380V 50HZ 3ph Can be customized |

| 15 | French Fries Spreading Machine | Set | 380V 50HZ 3ph Can be customized | |

| 16 | Freezer | 1 | Set | 380V 50HZ 3ph Can be customized |

| 17 | Упаковочная машина | 1 | Set | 380V 50HZ 3ph Can be customized |

French Fries Making Machine Factory

Преимущество

Универсальная фабрика пищевого оборудования

30 лет Р&История Д

Стабильная производительность оборудования

Доставка вовремя

Гарантия

12 Гарантия качества на месяц

Вся пожизненная техническая поддержка и обслуживание запасных частей

Услуга

Послепродажная поддержка в работе, обслуживание.

Бесплатное обучение онлайн или офлайн на заводе

Установка на месте на заводе Заказчика

Общие бизнес-советы для нового бизнес-планировщика.

Услуги доставки в страну покупателя

French Fries Machine Price

У нас есть профессиональная команда технических инженеров и команда разработчиков продукции для обновления нашей производственной линии для повышения эффективности., меньше производительности и больше удовлетворенности пользователей. Кроме, мы понимаем и быстро реагируем на потребности клиентов, предлагая правильное решение для их бизнеса.

You are most welcomed to contact our team now for a french fries manufacturing plant cost..

What is the best potato used for frozen french fries line?

Shepody is a white-skinned potato cultivar that originated in New Brunswick, Canada and is used for boiling, выпечка, and French frying. Its dry matter 19-21%, low reducing sugar content≤ 0.4% , especially suitable for frying processing.

Что еще, french fries in fast food restaurants and potato chips in supermarkets are mass-produced in factories. The well-shaped, light-eyed Shepody is easy to peel during production, and the resulting potato chips and french fries rarely showing holes and scars.

Поэтому, Shepody is ideal potato types for frozen french fries production.

Сопутствующие машины

Potato chips machines, линия по производству банановых чипсов, Пенаутс фритюрная линия. фритюрница непрерывного действия, small scale potato chips production line