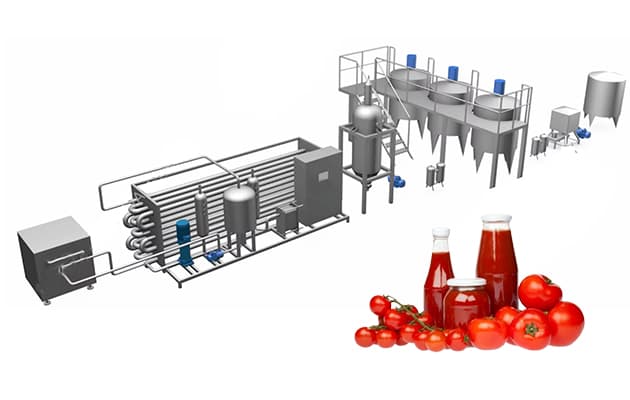

Tomato sauce making machine play a crucial role in the food manufacturing industry. They transform fresh tomatoes into products like tomato paste, ketchup, puree, and sauces through a series of automated and semi-automated stages.

We’ll explore how a modern tomato processing line works—from the raw fruit to the final packaging—highlighting each machine used in the tomato paste manufacturing process.

What is a Tomato Sauce Making Machine?

A tomato sauce making machine is any equipment used to clean, crush, refine, concentrate, sterilize, and package tomatoes. These machines are widely used in tomato paste processing plants to increase efficiency, maintain hygiene, and ensure product consistency.

Depending on the scale of production, tomato processing equipment may include standalone units or fully automated tomato paste production lines.

Step 1: Fresh Tomato Receiving, Sorting, and Washing

The tomato paste manufacturing process begins with sorting and washing.

- Tomato sorting machine: Optical sorters or manual conveyor belts remove leaves, stones, unripe or rotten tomatoes.

- Tomato washing machine: High-pressure water jets and air bubble washers ensure that tomatoes are thoroughly cleaned.

Efficient washing prevents contamination and improves the quality of the final tomato paste.

💡 Tip: Industrial tomato processing equipment with a capacity of 1–100 tons/hour is commonly used for bulk tomato paste production.

Step 2: Crushing and Pulping Machine

Clean tomatoes are then transferred to the tomato crushing machine, also known as the pulper or pulping machine.

- Funcţie: It breaks down tomatoes into a slurry made of juice, pulp, and skins.

- Preheating unit: The mixture is heated briefly (usually 65–75°C) to deactivate enzymes and preserve the bright red color.

Some tomato processing plants use a pulper and finisher combination to streamline this stage.

Step 3: Refining and Filtering

Next comes refining to remove skins, seeds, and large particles.

- Tomato refining machine: Uses a mesh screen (0.4–0.8 mm) to filter the tomato slurry.

- Double-stage refiners: Improve yield and produce a finer, smoother puree.

- Homogenizer: Ensures uniform texture and better mouthfeel in the final paste.

This stage is vital in tomato puree processing as it defines the quality of the intermediate product.

Step 4: Evaporation – Concentrating Tomato Puree into Paste

The puree is concentrated into paste using a tomato paste evaporator, a key machine in the tomato paste processing plant.

- Vacuum evaporator: Removes water at lower temperatures (55–65°C) to prevent degradation.

- Types: Falling film evaporators and forced circulation evaporators are commonly used.

- Output: Tomato paste with a Brix level of 28–30% or more.

🔧 Machines used: FMC evaporator, Bertuzzi vacuum evaporator, or Alfa Laval evaporation system.

Step 5: Sterilization and Cooling

Sterilization is essential to ensure the tomato paste is shelf-stable and safe to consume.

- Sterilization equipment: Tubular sterilizers heat paste to 110–130°C for 30–40 seconds.

- Cooling unit: Rapidly cools the paste to below 40°C to lock in flavor and color.

Many tomato processing lines integrate CIP (Clean-In-Place) systems to maintain hygiene between batches.

Step 6: Filling and Sealing

Sterilized paste is now ready to be filled into containers.

- Tomato paste filling machine: Aseptic fillers handle bulk packaging (220L drums) or retail packaging (pouches, cans, jars).

- Sealing machine: Ensures airtight closure to avoid contamination.

🏭 Used in: Both small-scale tomato paste plants and large industrial factories.

Step 7: Labeling, Packaging, and Palletizing

Once sealed, the product moves to tomato paste packaging equipment.

- Labeling machines: Automatically apply printed labels with nutritional info, brand, and expiration date.

- Cartoning machine: Packs individual products into boxes.

- Palletizer: Automates the stacking of cartons for easy logistics and transportation.

This is the final step before tomato paste is sent to stores or exported globally.

Types of Tomato Processing Equipment

There are various types of tomato processing machines based on production scale and product requirements:

| Machine Type | Funcţie |

|---|---|

| Washing Line | Removes dirt and impurities |

| Crushing Machine | Pulping tomatoes into slurry |

| Refiner | Filters skins/seeds |

| Evaporator | Concentrates puree into paste |

| Sterilizer | Kills microorganisms |

| Filler | Packages paste into containers |

| Labeler/Packer | Final packaging and labeling |

Some fully automatic tomato paste machines integrate all of these processes in a single line, ideal for high-capacity operations.

Tomato Paste Manufacturing Process Flow Chart

Here’s a quick overview of the tomato paste processing flow:

- Tomato Receiving

- Sorting & Washing

- Crushing & Încălzire

- Refining

- Evaporation

- Sterilization

- Filling & Sealing

- Packaging & Labeling

Each of these stages is supported by specific tomato processing equipment designed for hygiene, safety, and high throughput.

Applications of Tomato Sauce Production Line

Modern tomato paste production lines are used by:

- Tomato paste manufacturers

- Ketchup and sauce producers

- Ready-to-eat meal factories

- Export companies

In recent years, many developing countries have started investing in tomato paste processing plants to reduce reliance on imports and add value to their agricultural output.

Popular Tomato Paste Machine Models

Some of the most trusted tomato processing machines in the industry include:

- DT Rotary Evaporators

- DT Tomato Processing Line

- DT Sorting Machines

- DT Sterilizers & Homogenizers

- DT Aseptic Filling Machines

These models are known for efficiency, durabilitate, and ease of maintenance.

Cost of Tomato Paste Production Line

The tomato paste machine price varies based on capacity, automation level, and brand.

- Small-scale line (0.5–1 ton/hour): $30,000–$80,000

- Mid-range plant (3–5 tons/hour): $120,000–$250,000

- Industrial line (10–20 tons/hour): $500,000–$1.5 million

When budgeting for a tomato paste factory, remember to include installation, training, and spare parts.

Concluzie

The tomato sauce making machine is the heart of any tomato product manufacturing operation. From cleaning fresh tomatoes to filling aseptic bags or retail cans, each step is optimized for hygiene, flavor retention, and efficiency. Whether you are planning to set up a small tomato paste factory or expand an existing plant, investing in the right Tomato Sauce Production Line is key to success.

Understanding the tomato sauce manufacturing process helps producers deliver high-quality products while reducing waste and improving productivity. With the right equipment and setup, you can turn fresh tomatoes into a globally loved condiment—efficiently and profitably.