In the bustling world of food processing, tomato ketchup reigns as a versatile condiment, gracing everything from burgers to pasta. Its ubiquitous presence in households and restaurants worldwide has transformed it into a multibillion-dollar industry. For entrepreneurs and food manufacturers looking to tap into this market, aturnkey tomato ketchup production line offers a streamlined solution to enter the fray. This comprehensive guide will walk you through the entire process, from tomato selection to packaging, while addressing critical factors like cost, equipment, and setup.

1. The Tomato Ketchup Production Process: From Farm to Bottle

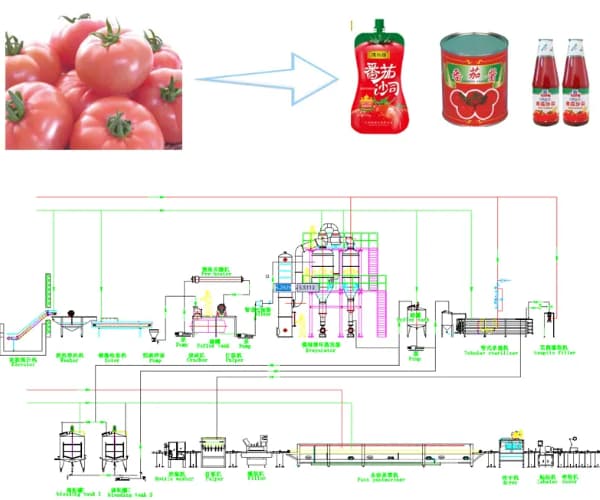

At the heart of every successful tomato ketchup manufacturing plant lies a well-defined production process. Let’s break down the key stages:

a. Tomato Selection and Preparation

The journey begins with high-quality tomatoes, typically ripe and firm varieties like Roma or California tomatoes. These are sorted to remove damaged or underripe fruit, ensuring consistency in the final product.

b. Washing and Sorting

Tomatoes enter the production line via a washing conveyor, where they’re thoroughly cleaned to remove dirt and debris. Advanced sorting systems use optical sensors to detect blemishes or foreign objects, enhancing product safety.

c. Crushing and Pulping

Washed tomatoes are crushed into a pulp using industrial-grade pulpers. This step breaks down the fruit’s cellular structure, releasing juice and separating skin and seeds.

d. Heating and Pasteurization

The pulp is heated to 85–90°C (185–194°F) to inactivate enzymes and microorganisms. Pasteurization ensures shelf stability while preserving the fresh tomato flavor.

e. Sieving and Refining

The heated pulp is passed through a sieve to remove skins and seeds, resulting in a smooth tomato concentrate. Refining may involve additional milling for a finer texture.

f. Seasoning and Blending

Here, the concentrate is blended with vinegar, zahăr, sare, and spices (de exemplu., ceapă, usturoi, cloves) to achieve the signature ketchup flavor. Precise dosing systems ensure consistency.

g. De-aeration and Homogenization

Air bubbles are removed to prevent oxidation, and the mixture is homogenized for a uniform texture.

h. Filling and Packaging

The finished ketchup is bottled or canned using automated filling machines, followed by labeling and sealing. Aseptic packaging options are popular for extended shelf life.

2. Key Components of a Turnkey Tomato Ketchup Production Line

A turnkey solution integrates all equipment needed to transform raw tomatoes into retail-ready ketchup. Essential components include:

- Washing and Sorting Systems: Automated conveyors with water sprays and optical sorters.

- Crushing and Pulping Machines: High-capacity pulpers designed for continuous operation.

- Pasteurization Units: Heat exchangers or steam-injected systems for efficient pasteurization.

- Sieving and Refining Equipment: Vibratory screens and colloid mills for texture control.

- Blending and Dosing Systems: Precision scales and mixers for accurate seasoning.

- Filling and Packaging Machines: Aseptic fillers, labelers, and carton sealers.

- Quality Control Tools: pH meters, viscometers, and metal detectors to ensure compliance.

Why Choose a Turnkey Solution?

- Efficiency: Pre-engineered systems minimize downtime and maximize output.

- Cost-eficiență: Bundled equipment often comes at a lower price than purchasing individually.

- Customization: Suppliers can tailor lines to specific capacities (de exemplu., 500 kg/hour to 20,000 kg/hour).

3. Cost Analysis: Budgeting for Your Tomato Ketchup Plant

The cost of setting up atomato ketchup manufacturing plant varies widely based on capacity, automation, and location. Here’s a breakdown:

a. Capital Expenditure (CapEx)

- Equipment: A small-scale line (500–1,000 kg/hr) starts at 250,000–500,000. Mid-scale (2,000–5,000 kg/hr) systems range from 800,000to2 milion.

- Land and Construction: Costs depend on location; urban areas may require 300,000–1 million for land and building.

- Utilities: HVAC, water treatment, and power infrastructure add 100,000–300,000.

b. Operational Expenditure (OpEx)

- Labor: Skilled workers, technicians, and quality control staff may cost 15,000–30,000/month.

- Raw Materials: Tomatoes account for 60–70% of production costs. Bulk pricing varies by region (e.g., 0.20–0.50/kg).

- Packaging: Bottles, labels, and caps add 0.10–0.30 per unit.

- Maintenance: Annual upkeep averages 5–10% of equipment cost.

Cost-Saving Tips:

- Source tomatoes locally to reduce transport costs.

- Invest in energy-efficient equipment to lower utility bills.

- Automate packaging to minimize labor expenses.

4. Setting Up Your Tomato Ketchup Factory

Launching atomato ketchup factory involves more than just equipment. Key considerations include:

- Location: Proximity to tomato farms reduces logistics costs. Access to ports/highways is critical for distribution.

- Compliance: Adhere to food safety standards (HACCP, ISO 22000) and local regulations.

- Workforce: Partner with vocational schools to train operators and technicians.

- Supply Chain: Establish relationships with packaging suppliers and logistics providers.

Example Setup Timeline:

- Planning: 3–6 months (feasibility study, permits).

- Constructie: 6–12 months (building, utilities).

- Installation: 2–4 months (equipment setup, testing).

- Launch: 1–2 months (staff training, trial runs).

5. Tomato Processing Plant vs. Tomato Ketchup Production Line

While both terms are related, they serve distinct purposes:

- Uzina de prelucrare a tomatelor: A broader facility that may handle multiple tomato products (paste, sauce, juice).

- Tomato Ketchup Production Line: A specialized setup focused solely on ketchup manufacturing.

A turnkey provider can design a modular line that integrates seamlessly into an existing plant or serves as a standalone facility.

6. Frequently Asked Questions (FAQs)

Q1: What’s the difference between tomato sauce and ketchup?

A: Ketchup is a smooth, seasoned condiment, while tomato sauce is thicker and often used in cooking. Ketchup requires additional steps like homogenization and precise seasoning.

Q2: How much does a tomato processing plant cost?

A: Costs range from 500,000(small−scale)la5 million+ (large-scale). Factors include automation level, capacity, and location.

Q3: Can I use any tomato variety for ketchup?

A: Roma or paste tomatoes are ideal due to their high pulp content and low moisture.

Q4: What’s the production time for ketchup?

A: From tomato to bottle, the process takes 2–3 hours, with pasteurization and cooling adding time.

Q5: How do I ensure consistent quality?

A: Implement rigorous quality checks at each stage, use standardized recipes, and calibrate equipment regularly.

7. Choosing the Right Turnkey Solution Provider–Mașină de mâncare DT

Selecting a supplier is critical. Look for:

- Experience: A proven track record in food processing.

- Customization: Ability to tailor solutions to your needs.

- A sustine: Training, întreţinere, and spare parts availability.

- Certifications: Compliance with international food safety standards.

DT Food Machine is a leading manufacturer specializing in tomato ketchup production lines, offering high-quality, efficient, and fully automated solutions for food processing industries worldwide. With years of expertise, we design and manufacture state-of-the-art tomato processing plants, ensuring precision, reliability, and cost-effectiveness.

Our turnkey solutions cover the entire tomato ketchup process, from raw tomato washing and pulping to cooking, pasteurization, and automated bottling. We provide customized ketchup making process solutions tailored to your production needs, ensuring compliance with international food safety standards.

At DT Food Machine, we prioritize innovation, durabilitate, and energy efficiency, helping our clients optimize production while minimizing costs. Whether you’re setting up a new tomato ketchup factory or upgrading an existing tomato sauce manufacturing plant, we deliver top-tier equipment and technical support to maximize your business success.

Partner with Mașină de mâncare DT today and experience superior tomato ketchup manufacturing solutions designed for efficiency, quality, and profitability. Contact us now to discuss your project requirements!

8. Concluzie: The Path to Ketchup Success

Launching a tomato ketchup brand is a journey that demands careful planning, investment in quality equipment, and adherence to food safety standards. A turnkey production line simplifies this process, offering efficiency, scalability, and cost predictability. By understanding the production process, costs, and setup requirements, you’ll be well-equipped to carve a niche in this competitive yet lucrative market.

Final Thought: The global tomato ketchup market is projected to reach $12 billion by 2028. With the right turnkey solution, your brand can be at the forefront of this growth.