Electric Waffle Cone Maker DT-18 Automatic Waffle Cone Maker

Electric waffle cone maker DT-18 is a versatile and efficient ice cream cone making machine, designed to make crispy, golden brown sugar cones. And it can also make waffle bowls, waffle rolls, waffle cones with same baking machine, but different forming machine.

Depending on the model, cel automatic waffle cones can be powered by electricity heating or gas heating, catering to commercial use with output ranging from 100 bucăți pe oră până la 1200 bucăți pe oră.

Materiale: stainless steel material cover

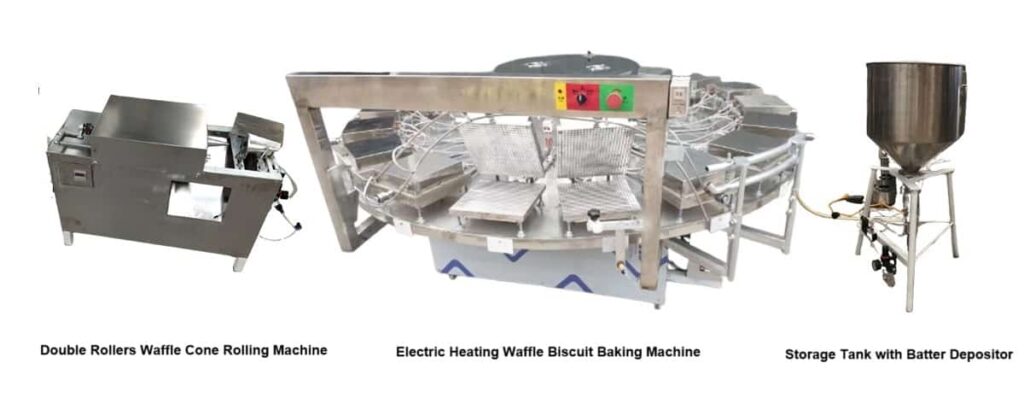

Full set of machine includes: Batter tank with dispensor, mașină de copt, cone rolling machine

Electric Ice Cream Cone Maker DT-18 Application

Electric waffle cone maker DT-18 is versatile and efficient in making crispy, golden brown ice cream cones. Due to the economical cost, user friendly, saving energy, and higher capacity, this waffle and waffle cone maker is excellent investment for various businesses and individuals such as ice cream shops, ice cream cone vendors and ice cream factory.

And commercial waffle cone maker DT-18 realize more than one size of sugar cones on one machine by adjusting biscuit size and rolling spare parts. Pe lângă asta, it can also make waffle rolls by adding egg roll rolling machine, and make waffle bowls by adding waffle bowl forming machine. Ce este mai mult, the cone maker baking machine can also make waffle biscuits, Italian pizzelles and Kuih Kapit etc. Într -un cuvânt, this waffle cone making machine has multi-function and popular and greatly improve production efficiency than their tradtional handmade ice cream cones.

Commercial Waffle Cone Maker for Sale DT-18 Introduction

Ice Cream Waffle Maker Machine Description

Electric waffle cone maker DT-18 is one of professional aparat de cornet de inghetata. And it allows ice cream waffle cone suppliers with higher quality waffle cones at amazing output to meet up increasing market demand and expand business. Pe lângă asta, by changing rolling spare parts, the ice cream cone producer can get more than one size of waffle cones. Ce este mai mult, to get a waffle bowl forming machine, customer can also produce waffle bowls. Prin urmare, one waffle and waffle making machine is favorite choice for new business starter or those who plan to update the ice cream cone production.

în timp ce, electric waffle cone maker DT-18 is a model enabling cutomer to produce about1000 pieces to 1200 bucăți pe oră. The complete set of automatic waffle cone maker DT-18 includes an electric heating waffle biscuit baking machine which has adjustable temperature controls on each baking plates, a batter storage tank with automated batter paste ejector, and a cone rolling machine. If customer expect to make waffle bowls too, then add a waffle bowl forming machine. Further to make ice cream cone production easier, we also have the batter paste mixer 60L to replace traditionally manual mixing process.

The condition for a customer to install the electric ice cream cone machine, is that their workshop shall be equiped with industrial three phases electricity and air source (4KW air compressor is recommended). And there will be one to two workers for whole ice cream cone production from raw material preparation to machine operation and package.

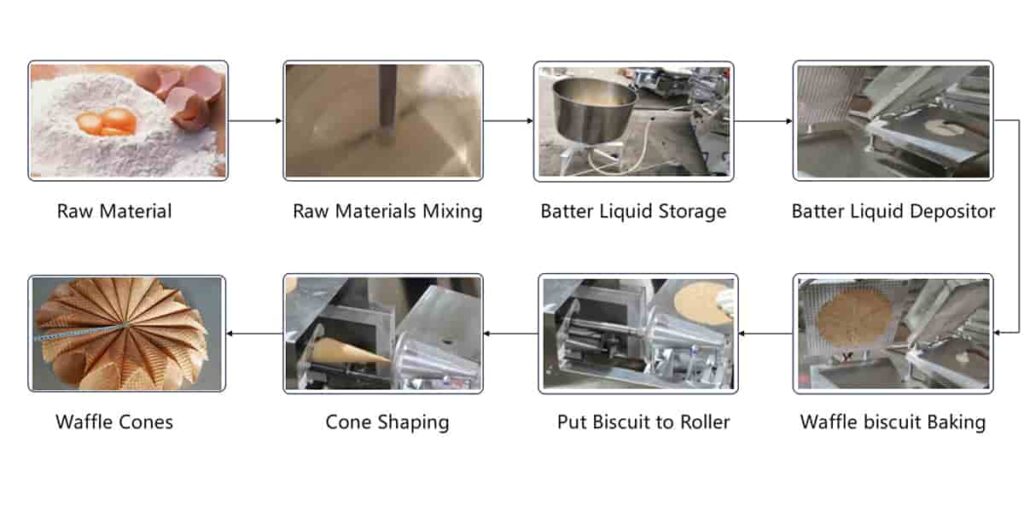

Extra Large Waffle Cone Maker DT-18 Sugar Cone Waffle Cone Production Process

To make crispy cones, the waffle cone maker is designed based on the waffle cone production process.

- Materii prime: Wheat flour, zahăr, water etc preparation

- Well mix all raw materials at good ratio which is essential to quality waffle biscuit

- Keep the well mixed batter liquid in storage tank and deposit the set amount of batter to baking.

- Baking process requires accurate temperature control and setting for making uniform cones with bright color.

- After waffle biscuit is baked well, quickly to roll into waffle cones when waffle biscuit is still soft.

- Measuring the waffle cones to make sure the size is what you need, and then pack them into cartons.

Giant Waffle Cone Maker DT-18 Specification

Model: Automatic Waffle cone machine with electric heating

Capacitate:1000 to 1200pcs/h

Preţ: Cel mai bun preț, aprovizionare directă din fabrică cu cea mai înaltă calitate

Sursa de incalzire:Incalzire electrica

Materialul mașinii: Pentru aparatul comercial de conuri de vafe, cadrul de susținere și scutul de acoperire a mașinii sunt realizate din oțel inoxidabil 201 prin standard. Este pentru siguranța alimentelor și pentru scopuri ușor de curățat.

Electric Ice Cream Cone Maker Parameter

Model | DT-6 | DT-9 | DT-12 | DT-15 | DT-18 |

Capacitate | 300 la 400 buc/h | 400 la 600 buc/h | 600 la 800 buc/h | 800-1000 buc/h | 1000-1300buc/h |

Putere de încălzire | 10kW | 15kW | 19.5kW | 23kW | 28kW |

Dimensiune | 150*150*125cm | 160*160*125cm | 170*170*125cm | 180*180*125cm | 190*190*125cm |

Automatic Waffle Cone Machine DT-18 Features

Waffle Cone Baker Electric Heating

Batter Tank with Dispensor

Electric heating baking machine is waffle biscuit baking machine. It is powered by electricity 380V 50HZ three phase, or at customized voltage.

Separate heating control on each baking plates.

Batter paste amount is adjustable to achieve required biscuit size. The machine has the automatic dipensor to deposit the fixed amount to baking machine

waffle cone maker roller

Ice Cream Waffle Bowl Maker

The rolling machine has two roller to compete the capacity of baking machine.Making more than one size of cones, the two roller spare part needs to be replaced to match the cone size.

Worker remove waffle biscuit from baking machine and put it on waffle cup making machine to make waffle bowl, star waffle etc.

It has two bowl forming machine to meet capacity of baking machine

Mixer de aluat

Industrial Piston Air Compressor 4kW

Batter mixer is to mix all ingredients together into batter paste. It is optional tool to prepare the batter paste. The tank volume is 60L.

Air compressor is needed to support the waffle cone maker. And customer shall have it ready and suggested Model V-0.6/8, Air volume 0.6cbm/min, Volume 115L, Putere: 4KW, Voltage 380V

Automatic Waffle Cone Maker DT-18 Advantage

Consistency and Quality

The sugar cone maker give consisitant heating to waffle biscuit baking, which ensures the golden-brown color, consistent texture and flavor. This is especially beneficial for businesses that rely on repeat customers and need to maintain a high level of quality.

Efficiency

Waffle cone making machine requires one worker to receive waffle biscuit and put it on rolling machine within 2seconds. It reduces a lot labor and ensure higher output.

Versatility

In addition to sugar cones, waffle cone and bowl maker also be used to make waffle cones, sugar cones, boluri de vafe, waffle biscuit etc which offers versatility and expanding your product offerings.

Customizability

Commercial cone maker can realize logo on waffle cones by customize the baking molds. This is to help customer to influence market with their own brand.

Pe lângă asta, to make more than one sugar cones in one machine, customer may get addtional rolling machines or they can only get addtional rolling spare parts to replace when they need switch between cone sizes.

How to use a sugar cone waffle maker DT-18?

The wafer cone making machine is simple to use. in orice caz, fiecare operator trebuie să citească și să respecte Registrul de operare al mașinii pe care îl oferim pentru fiecare comandă. Iată pașii scurti de urmat:

- Poziționați mașina de conuri de vafe de înghețată pe un teren plat. Reglați șuruburile de ancorare pentru a ridica roțile de pe sol.

- Conectați sursa de aer de la compresorul de aer la mașina de formare sau numită mașină de rulare și rezervorul de aluat de chituire.

- Mașină de formare a conurilor de priză, cimentarea aluat rezervorul de aluat la mașina de coacere biscuiți.

- Conectați mașina de copt la cablul de alimentare din fabrică;Poziționați duza pentru aluat de la mașina de chituit în mijlocul plăcii de copt.

- Porniți mașina de copt. (Timpul de coacere și temperatura de coacere sunt prestabilite înainte de livrare, dar este reglabil pe site-ul utilizatorului în funcție de nevoia produsului.

- După producție, deconectați fiecare mașină, și întrerupe curentul electric. Curățați mașina de copt, mașină de formare și cimentare rezervor de aluat conform cărții utilizatorului.

stainless steel ice cream wafer maker DT-18 Manufacturer

Durabil și stabil

Mașina este proiectată să lucreze continuu 8 ore pe schimb. Dar clientul ar putea prelungi perioada de producție în funcție de comanda lor pe piață. Și produce cornet de înghețată cu culoare uniformă și dimensiuni consistente. Calitatea conului este bună și ajută clienții noștri să câștige mai multă reputație pe piață și efect de marcă.

Calitate și servicii garantate

Mașinile cu conuri de vafe de calitate măresc capacitatea de producție și clientul plătește mai puțin costul de întreținere.

Pe lângă asta, oferim 12 luni garantie de calitate, ghid de instalare și service și suport tehnic pentru întreaga viață, și furnizarea de piese de schimb pentru întreaga viață.

Mai multă valoare pentru client

Aparatul alimentar DT oferă o soluție completă de la comanda dvs. de mașină, livrare , instalare, rețete de conuri de vafe pentru a vă ajuta să porniți și să reușiți afacerea dvs. alimentară.

Pe lângă asta, facem afaceri personalizate pentru clientul nostru,pentru a satisface cerințele lor personalizate cu privire la forma produsului final, dimensiunea și modelul sau designul logo-ului. De asemenea, acceptăm producția OEM și ODM pentru distribuitorii noștri de mașini.

Waffle Cone Machine Price waffle Cone Maker for Sale

When considering the price of a sugar cone maker, it’s essential to weigh the cost against your production needs and budget.

Our commercial waffle cone making machine is suitable medium scale business . And for large scale factory production, we have full automatic waffle cone machine.

While for customer to choose model, it is essential to think about the output that they need, their factory power, the market demand at present and future etc. We love to share experience with you and welcome to contact our team now.

What are sugar cones made of ?

The sugar cones is crispy and sweet. Ingredientele sunt faina de grau, zahăr, ulei comestibil, sare, si apa etc. Vă vom oferi un raport de bază pentru rețete după comandă și puteți adăuga ingredientele secrete pentru a avea o aromă și un gust deosebit.

Mașini înrudite

Linie automată de producție a cornetului de înghețată, aparat de fabricare a conurilor de napolitană, mixer pentru aluat, compresor de aer 4KW