In the global food industry, pasta remains a universally loved staple. Behind every strand of spaghetti or piece of macaroni is a well-designed pasta production line. This article explores everything you need to know about pasta production lines, from machinery types and configurations to well-known brands and market pricing.

What Is a Pasta Production Line? Components, Performance, Capacitate, și Preț

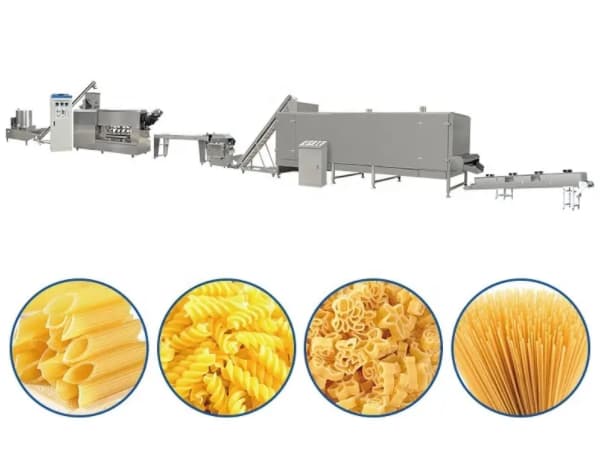

A pasta production line is an integrated system designed for large-scale manufacturing of pasta from raw materials such as durum wheat semolina or soft wheat flour. The system automates the process of mixing, kneading, extruding, shaping, drying, and packaging pasta, ensuring consistency and efficiency.

Main Components:

- Dosing and Mixing System: Precisely measures ingredients and blends them into uniform dough.

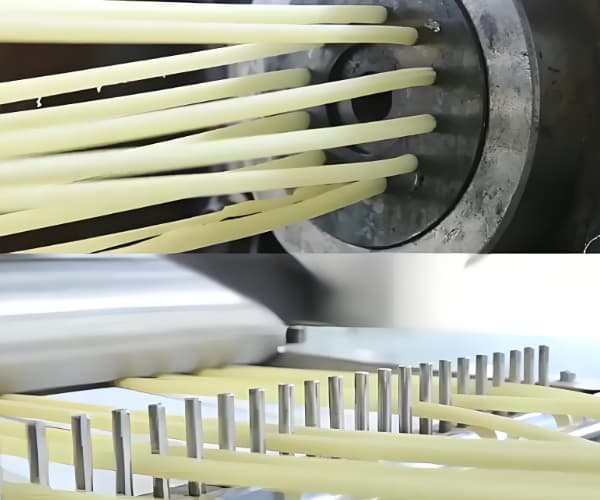

- Vacuum Extruder: Shapes the dough through various dies to produce different pasta shapes.

- Pre-Dryer and Dryer Units: Stabilize and remove moisture gradually, ensuring shelf stability.

- Cooler and Conveyor Belts: Prepare pasta for packaging and reduce temperature.

- Cutting and Packaging Machines: Finalize shape (de exemplu., short or long cut), weigh, and pack the pasta.

Performance:

- High automation reduces labor and error.

- Moisture sensors and temperature control improve product consistency.

- Energy-efficient components lower operational costs.

Production Capacity:

- Ranges from 100 kg/h for small-scale units to 6,000 kg/h or more for industrial operations.

Price Range:

Production CapacityPrice Range (USD)100–300 kg/h$60,000 – $150,000500–1,000 kg/h$180,000 – $400,0001,500–3,000 kg/h$450,000 – $1,200,000Custom High Output$1.5M – $3M+

Prices vary based on the brand, automation level, optional components, and installation services.

Pasta Line: Overview of an Integrated System

A pasta line refers to the full equipment chain required to produce pasta. Modern pasta lines integrate digital monitoring, touch-screen controls, and automated inspection systems for streamlined production. They’re available for both short and long-cut pasta and can include fresh or dry pasta configurations.

Macaroni Production Line: Specialized for Short-Cut Pasta

Macaroni production lines are tailored for producing elbow macaroni, penne, fusilli, and similar shapes. Key machinery includes:

- Dough mixers with dosing controls

- High-pressure vacuum extruders

- Short-pasta cutting heads

- Pre-drying tunnels and dryers

- Cooling and packaging lines

Short-cut lines are ideal for large-scale food suppliers and retail packagers.

Spaghetti Production Line: Long-Cut Pasta Perfection

Spaghetti and long-cut pasta require specific drying and cutting methods. These lines include:

- Mixing and vacuum extrusion systems

- Stick hanging equipment

- Vertical multi-zone dryers

- Cutting and packing machines

These systems preserve pasta integrity and avoid breakage during processing.

Buhler Pasta Line: Swiss Engineering at Its Finest

Buhler is renowned for high-precision food machinery. Their pasta lines are known for:

- Modular automation

- Stainless steel hygienic design

- Real-time digital monitoring

- High energy efficiency

- Capacities of up to 6,000 kg/h

Buhler offers pasta lines for every product type and manufacturing scale.

Dry Pasta Production Lines: Shelf-Stable and Scalable

Dry pasta lines are designed for long-lasting, packaged pasta products. Ideal for export and retail, they feature:

- Pre-drying tunnels

- Multi-zone drying ovens

- Cooling conveyors

- Quality control sensors

These lines support consistent production with minimal operator intervention.

Axor Pasta Line: Innovation from Italy

Axor is an Italian company offering modular pasta lines for dry and fresh pasta. Features include:

- Compact footprint

- Fast product changeover

- High-speed extrusion

- User-friendly PLC interface

Axor systems suit medium-to-large pasta manufacturers.

Braibanti Pasta Line: Tradition Meets Technology

One of the oldest names in pasta technology, Braibanti blends legacy with innovation. Benefits include:

- Rugged, long-life components

- Short and long pasta configurations

- Easy integration with legacy systems

- Trusted across decades by global manufacturers

Long Cut Pasta Production Line: Precision Drying and Shaping

Long cut pasta lines need careful moisture control and shaping mechanisms. These lines include:

- Vertical dryers with stick suspension

- Vacuum extruders with specialty dies

- Auto-lowering hangers and conveyors

- Programmable temperature zones

Ideal for spaghetti, fettuccine, and linguine manufacturers.

Pasta Making Line: From Raw Ingredients to Final Packaging

A pasta making line offers complete automation from flour to final package. The process includes:

- Ingredient dosing and mixing

- Extrusion into chosen shapes

- Pre-drying stabilization

- Controlled final drying

- Cooling and quality check

- Packaging and labeling

Such lines reduce contamination risk and improve operational speed.

Pasta Production Line Price: How Much Should You Invest?

Pasta production line pricing depends on several factors:

- Capacitate (kg/h)

- Type (short or long cut)

- Brand and country of origin

- Automation level

- Installation and after-sales services

Ensure to compare total cost of ownership, not just upfront price.

CapacityPrice Range (USD)Entry-Level$60,000 – $150,000Mid-Level$180,000 – $400,000High Output$450,000 – $1,200,000Industrial Scale$1.5M – $3M+

Why Choose DT Food Machine as Your Pasta Line Supplier?

If you’re looking for a reliable, high-quality pasta production line, Mașină de mâncare DT is your go-to manufacturer and supplier. With years of expertise, DT offers:

- Fully customized pasta production solutions

- High-performance, energy-efficient equipment

- Competitive pricing and flexible configurations

- Comprehensive after-sales support and training

From macaroni to spaghetti, from dry pasta to long-cut configurations, DT Food Machine delivers trusted systems that meet global food safety standards.