Máquinas de batatas fritas Máquinas de batatas fritas Linha automática de batatas fritas

Máquinas de batata frita são equipamentos de processamento de batata, desde batata crua até batatas fritas crocantes.

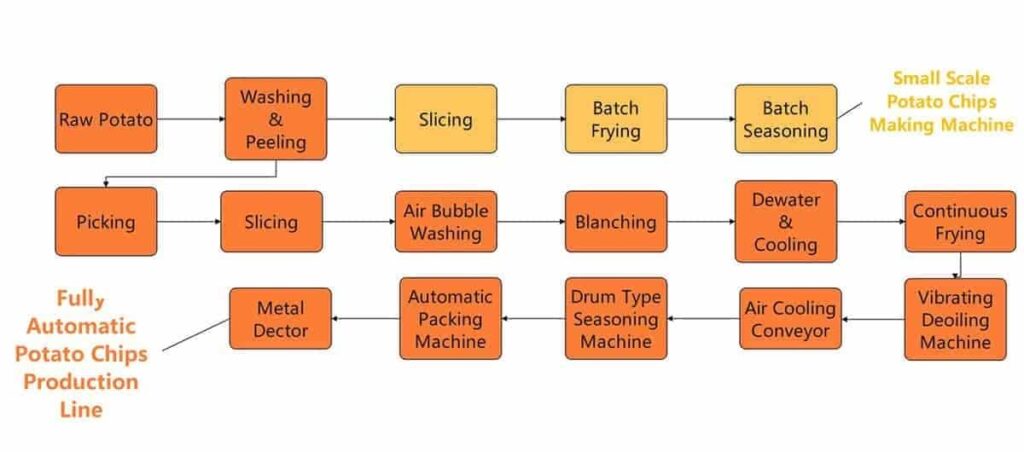

Linha automática de batatas fritas contém lavagem de batata e máquina de descascar, máquina de cortar chips, máquina de branqueamento para batatas, máquina de desidratação de batatas fritas, fritadeira de batata frita, Máquina de Deoiling, máquina de resfriamento, máquina de tempero de batatas fritas, máquina de embalagem de batatas fritas e seus equipamentos e funções auxiliares para tornar toda a linha totalmente automática e funcionando continuamente.

Aplicado a: Batatas fritas, batatas fritas, chips de banana etc..

Capacidade: 50-100kg/hora, 100-150kg/hora, 200-250kg/hora, 350-400kg/hora, 450-500kg/hora, e maior capacidade.

Aplicação de máquinas de batata frita

Máquinas de batata frita são usados em fábricas de batatas fritas com plantas de processamento de batata de tamanho grande ou médio. Devido à alta eficiência de produção e alimentos higiênicos,linha de batatas fritas totalmente automática garante aos investidores menos custo de produção e mais participação de mercado, portanto, obter melhor retorno do investimento.

E, máquina de fazer batatas fritas em pequena escala é bom para empresas de processamento de alimentos que planejam iniciar um pequeno negócio.

Além do mais, máquina para chips também pode personalizar a linha para fazer chips de dedo, chips de banana , chips de batata doce, etc..

Introdução à máquina de batatas fritas

Descrição do fabricante de batatas fritas

A máquina de fazer batatas fritas é uma solução de processamento de batata na lavagem de batata, peeling, branqueado, fritar, Tempero e embalagem. E as linhas de fichas são altas capacidade, super eficiência com alimentos qualificados e higiênicos.

Embora para atender a diferentes demandas de negócios, projetamos linha de produção semiautomática de batatas fritas com capacidade de 20-50kg/h ou 50-100kg/h. Mas também projetamos máquinas totalmente automáticas de batatas fritas com capacidade de até 500KG / H e maior capacidade pode ser personalizada.

Especificação da máquina para fazer batatas fritas

Método de aquecimento: Aquecimento elétrico / Aquecimento a Gás

Materiais da Máquina: Qualidade alimentar 304 materiais de aço inoxidável, melhor qualidade feita

Temperatura de aquecimento do óleo: 0℃ a 300 ℃ (Fahrenheit 32°F a 572.0 °F)

Proporção de batata e batata frita: 4 : 1 para referências.

Capacidade: 50KG/H a 500KG/H (Maker de maior capacidade é capaz de ser personalizada)

Requisito de espaço de fábrica: Podemos personalizar a linha de produção com base no tamanho da fábrica e na planta baixa.

Fluxograma da linha de produção de batatas fritas

Características da linha de produção de batatas fritas

Máquina de descascamento de batata

Para linha de produção de chips em escala comercial, bmáquinas de descascar batatas tipo atch tem mais vantagem de lavagem eficiente e maior taxa de descascamento do que o trabalho manual.

E para linha de produção de batatas fritas totalmente automática, é necessário levar a máquina contínua de lavar e descascar batatas. Trabalhando com um elevador, realizará a alimentação contínua de batata crua, lavar, processo de descascamento e descarga.

Além do mais, A máquina de descasque do tipo Sprial empurrou a batata e descarrega da outra extremidade para a colheita de correias de transportador antes de fatiar o processo.

Portanto, A máquina automática de descascar batatas é usada em linhas de produção de batatas fritas de média e grande capacidade.

Além disso, É adequado para lavar e descascar batata, batata doce, cassava, ruivo, cebola, cenouras etc..

Máquina fatiadora de chips

A máquina cortadora de batata pode cortar fatias de batata com espessura uniforme. E a espessura da fatia pode ser ajustada de acordo com a necessidade.

Além do mais, existem diferentes modelos de máquina cortadora de batatas fritas com base na capacidade de produção e necessidade.

Batatas branqueadas antes de fritar

Em uma linha automática de produção de batatas fritas com grande capacidade, a máquina de branqueamento desempenha um papel importante para proteger a cor do chip e manter o sabor dos produtos.

Batata Chips Time de ramificação é sobre 5 a 15 minutos à temperatura da água quente 70 ℃ (158.0 ° f)

Existem máquinas de ramificação contínua com aquecimento a gás e máquinas de ramificação contínua com aquecimento elétrico para o cliente escolher.

Além do mais, a máquina de ramificação também não é boa apenas para ramificar batatas fritas, mas também chips de banana, batatas fritas e outros materiais.

Máquina de desidratação de batata

A máquina de resfriamento a ar remove a água e esfria a temperatura das batatas fritas ramificadas antes de fritar.

E ter melhor efeito, É necessária uma necessidade de uma Macine vibratória antes de ser usada antes da secagem e desidratação do ar, correia transportadora.

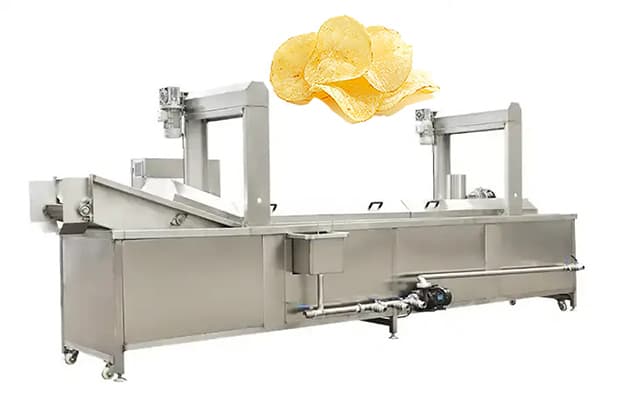

Máquina de fritar batata

Para planta de batata de pequena escala, a linha de fritura semiautomática é a escolha ideal que contém frituras redondas.

No entanto, para unidade automática de produção de chips, o máquina de fritar contínua é necessário para manter o tempo de fritura contínuo trabalhando com maior capacidade e menos trabalho. E os chips fritos precisam ser de maior qualidade, com cor frita uniforme e bom gosto. Além do mais, o sistema de reabastecimento de óleo, sistema de reciclagem de óleo, o sistema de filtragem de óleo e o sistema de autolimpeza da máquina melhorarão muito a eficiência da produção, prolongar o uso de óleo e chips de melhor qualidade.

Máquina de Deoiling

A máquina vibratória de desengorduramento é necessária para remover o óleo dos chips fritos após a fritura.

Porque, os chips fritos da linha de fritura normalmente contêm alguns óleos que tornam o produto oleoso e podem poluir a área de produção. Portanto, A máquina vibratória com placas de recebimento de óleo é bom para destacar o óleo da superfície dos chips e manter o local de produção limpo.

O que é mais, durante o processo de vibração, Os chips estão se movendo e se espalham até para o próximo processo.

Máquina de resfriamento

O transportador de resfriamento é instalado com ventiladores que sopram o vento nos cavacos. Portanto, a temperatura dos chips cai drasticamente devido ao vento forte natural. Este é um processo importante antes do processo de tempero e embalagem. Os chips totalmente resfriados ficarão mais crocantes e terão vida útil mais longa.

Projeto opcional: rede à prova de vento é necessária para evitar que lascas saiam das correias transportadoras.

E a placa de recepção de óleo sob o transportador de resfriamento é opcional para receber qualquer óleo adicional que caia dos cavacos.

Máquina de tempero de batata frita

Máquina de tempero tipo tambor funciona com tempero em pó, tempero picante, sal, e também pode ser personalizado com pulverização de óleo, etc.. de acordo com a necessidade de produção.

Para linha de chips, depois de esfriar os chips, é necessário um transportador para enviar os chips para o tambor de tempero continuamente para misturar os temperos com os chips uniformemente.

E na saída, há um design de malha para permitir tempero adicional e os resíduos caem em um prato receptor. Devido a esse design, os chips são apenas com a quantidade certa de temperos e ótimo sabor.

Embalando máquina automática com pesagem, Recheio e fabricação de bolsas

Para embalar chips em sacos plásticos automaticamente, a máquina de embalagem automática de chips é a escolha ideal. Normalmente, máquina de embalagem automática de chips deve incluir elevador, Pesar de várias cabeças, flatform, Dispositivos de fabricação de bolsas com função de impressão de data, e um transportador de produto final.

E, para embalar chips, a função do nitrogênio é necessária para manter os chips com longa vida útil e fornecer proteção durante o transporte.

O que é mais, A máquina de embalagem de chips tem vantagem de alta eficiência, pesagem precisa, e trabalhando continuamente com linha de produção de chips.

Parâmetro da máquina fabricante de batatas fritas

Linha de produção de batatas fritas totalmente automática DT-PC-500, capacidade 450-500kg/h para referência.

| Nome | Consumo de energia | Taxa de tensão |

| Elevador com bunker | 0.75 kW | 380V 50Hz 3ph, capaz de personalizar |

| Máquina de lavagem e descascamento de batata | 4.75 kW | 380V 50Hz 3ph, capaz de personalizar |

| Transportador de coleta | 0.75 kW | 380V 50Hz 3ph, capaz de personalizar |

| Máquina cortadora de batatas fritas | 1.1 kW | 380V 50Hz 3ph, capaz de personalizar |

| Máquina de branqueamento | 70 kW | 380V 50Hz 3ph, capaz de personalizar |

| Máquina de desidratação vibratória | 1.5KW | 380V 50Hz 3ph, capaz de personalizar |

| Linha de desidratação de resfriamento de ar | 15 kW | 380V 50Hz 3ph, capaz de personalizar |

| Transportador de elevador antes de fritar | 0.75 kW | 380V 50Hz 3ph, capaz de personalizar |

| Máquina de fritar batatas fritas | 204.5 kW | 380V 50Hz 3ph, capaz de personalizar |

| Máquina de Deoiling Vibratando | 1.5 kW | 380V 50Hz 3ph, capaz de personalizar |

| Linha de secagem de resfriamento de ar | 8 kW | 380V 50Hz 3ph, capaz de personalizar |

| Eelvator para temperar | 0.75 kW | 380V 50Hz 3ph, capaz de personalizar |

| Máquina de tempero | 1.5 kW | 380V 50Hz 3ph, capaz de personalizar |

| Máquina de embalagem totalmente automática de batata | 6.5KW | 380V 50Hz 3ph, capaz de personalizar |

Fabricante de linha de batatas fritas

Vantagem da fábrica de máquinas de fritar

Fábrica completa de máquinas para alimentos

30 anos R&História D

Desempenho estável de máquinas

Entrega no prazo

Garantia

12 Meses de Garantia de Qualidade

Suporte técnico vitalício e serviço de peças de reposição

Serviço

Suporte pós-venda em operação, manutenção.

Treinamento gratuito on-line ou off-line na fábrica

Instalação no local na fábrica do cliente

Consultoria geral de negócios para novo planejador de negócios.

Serviços de entrega para o país do comprador

Preço da linha de produção de batatas fritas

Temos uma equipe profissional de engenheiros técnicos e uma equipe de desenvolvimento de produtos para atualizar nossa linha de produção para maior eficiência, menos produção e melhor satisfação do usuário. Além do mais, entendemos e respondemos rapidamente às necessidades dos clientes com a solução certa para seus negócios.

Você é mais bem -vindo para entrar em contato com nossa equipe agora para uma solução de fritura e cotação.

Máquinas Relacionadas

Linha de produção de batatas fritas, linha de produção de chips de banana, linha de fritura de penautas. fritadeira contínua, Linha de produção de batatas fritas em pequena escala