Máquina de batatas fritas congeladas French Machine Automática Fries Processing Plant

Francês Linha de produção de batatas fritas é uma solução de produção automática e avançada no processamento de batatas em batatas fritas.

Planta automática de processamento de batatas fritas contém lavagem de batata e máquina de descascar, Máquina de cortador de batatas fritas, máquina de branqueamento, Máquina de desidratação, Máquina de fritadeira de batatas fritas, Máquina de Deoiling, máquina de resfriamento, Freezer rápido, máquina de embalagem automática e seus equipamentos auxiliares.

Aplicado a: Batatas fritas, chips de batata doce, lascas longas de banana, batatas fritas, Fritas francesas frescas, batatas fritas congeladas, chips de banana etc..

Capacidade: 50-100kg/hora, 200-250kg/hora, 350-400kg/hora, 500kg/hora, 1000kg/hora, 1500kg/hora, 2000kg/h e capacidade personalizada.

Aplicação de linha de produção de batatas fritas congeladas

Máquina de fabricação de batatas fritas congeladas é uma solução avançada para fabricantes de batatas fritas congeladas. Não é watter é uma linha automática de produção de máquinas de batatas fritas de batata para fábricas maiores de batatas fritas, ou linha de produção de batatas fritas congeladas em pequena escala para fábrica de tamanho médio ou nova fábrica de batatas fritas. Nossas plantas de processamento de batata permitem investidores com bons retornos, reduzindo bastante o trabalho, melhorando a qualidade do produto, fornecendo produtividade e participação de mercado.

Máquina de fabricação de fichas congeladas também é popular entre os fabricantes de alimentos para lanches que desejam que a linha faça várias fichas, como batatas fritas, chips de banana, batatas fritas de batata -doce etc. E devido à sazonalidade das matérias -primas, Eles precisam de uma linha de produção para a produção fora da temporada produzir outros produtos.

Introdução à linha de produção de batata congelada

Descrição da linha de produção de batatas fritas congeladas

Máquina de batatas fritas francesas comerciais é uma linha de produção completa que cobre a máquina de lavar e descascar de matérias -primas, máquina de branqueamento, cortador de batata, Fria francesa fritura, Freezer rápido, Máquina de pesagem e ensacamento automático.

E personalizamos a fábrica de processamento de batata para atender a diferentes tamanhos de negócios. Portanto, Temos uma linha de produção semi -automática de batatas fritas por capacidade de 50 kg por hora, mas também em pequena escala Fries Fries Line com saída de 100 kg por hora, e produção de batatas fritas congeladas totalmente automática linha até 2000 kg por hora. Além do mais, Personalizamos a máquina de fabricação de batatas fritas com a capacidade necessária pelo cliente.

Linha de produção de batatas fritas para especificação de venda

Método de aquecimento: Aquecimento elétrico / Aquecimento a Gás

Materiais da Máquina: Qualidade alimentar 304 materiais de aço inoxidável, melhor qualidade feita

Temperatura de aquecimento do óleo: 0℃ a 300 ℃ (Fahrenheit 32°F a 572.0 °F)

Capacidade: 50Kg/h a 2000kg/h (maior capacidade pode ser personalizada)

Requisito de espaço de fábrica: Podemos personalizar a linha de produção com base no tamanho da fábrica e na planta baixa.

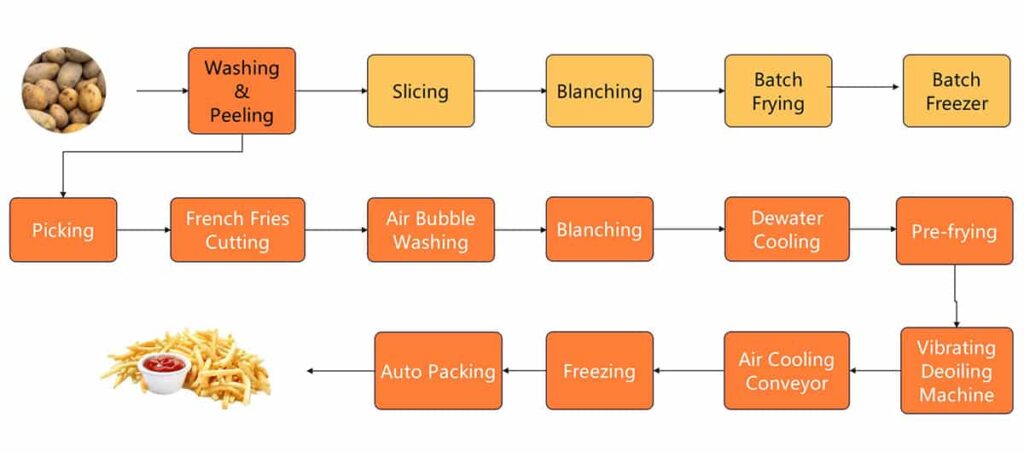

Fluxograma de máquina de batatas fritas totalmente automática

Inclui Linha de produção de batatas fritas em pequena escala.

Recursos de batatas fritas

Máquina de descascamento de batata

Isso é uma máquina de lavar e descascar lavar, descascar e descarregar.

Porque as escovas irregulares e corrugadas são compostas de pincel de cerdas duras e escova de esmeril que permitem descascar completamente as batatas.

Além do mais, A máquina de descasque do tipo Sprial empurrou a batata e descarrega da outra extremidade para a colheita de correias de transportador antes de fatiar o processo.

Além disso, É adequado para lavar e descascar batata, batata doce, cassava, ruivo, cebola, cenouras etc..

Máquina de cortador de batata frita francesa elétrica

Máquina de corte de batatas fritas de batata é um cortador comercial de batatas fritas com alta saída. E bastões franceses tamanho 7*7mm, 8*8milímetros, 10*10milímetros, e feito sob medida pode ser alterado ajustando a lâmina.

A máquina de cortador de batatas fritas também é adequada para outros vegetais de raiz, como cenouras, cassava, etc..

O produto final é suave, uniforme e livre de pausas.

Batatas branqueadas antes de fritar

Esta é uma máquina de branqueamento para proteger a cor francesa e permanecer com o gosto dos bens.

Batata Chips Time de ramificação é sobre 5 a 15 minutos à temperatura da água quente 70 ℃ (158.0 ° f). E a correia de malha de aço inoxidável é com regulação da velocidade de conversão de frequência, Então o tempo e a velocidade de branqueamento são ajustáveis.

Existem máquina de ramificação contínua com aquecimento a gás e máquina de ramificação contínua com aquecimento elétrico para o cliente escolher.

Máquina de desidratação de batata

Máquina de resfriamento de ar remove a água e esfria a temperatura das varas de batata ramificadas antes de fritar. Isso diminui o tempo de fritura e garante o sabor da qualidade das batatas fritas.

E ter melhor efeito, É necessária uma necessidade de uma Macine vibratória antes de ser usada antes da secagem e desidratação do ar, correia transportadora.

Máquina de fritadeira de batatas fritas

Para planta de batata de pequena escala, A fritadeira do tipo de cesta ou a máquina de fritura redonda é a escolha ideal para capacidade abaixo de 200 kg por hora.

No entanto, Para fábrica de batatas fritas totalmente automática, a máquina de fritar contínua é a melhor opção para manter o tempo de fritura contínuo trabalhando com maior capacidade e menos trabalhos. Melhor máquina de batatas fritas é materiais de aço inoxidável e seu tempo de fritura é ajustável e a temperatura do óleo ajustável.

Além do mais, Também podemos personalizar a fritadeira para automatizar o processo de recarga de óleo, reciclagem de óleo, Sistema de filtragem de óleo e auto -limpeza. Isso melhorará bastante a eficiência da produção, prolongar o uso de petróleo e as batatas fritas de qualidade de apostas.

Máquina de Deoiling

Máquina de Deoiling vibratória é necessária para remover o óleo na superfície das batatas fritas após fritar.

Porque, Os paus franceses fritos da linha de fritura normalmente carregam alguns óleos que causam o produto oleoso e podem poluir o piso de produção. Portanto, A máquina vibratória com placas de recebimento de óleo é bom para destacar o óleo da superfície dos chips e manter o local de produção limpo.

O que é mais, durante o processo de vibração, Os chips estão se movendo e se espalham até para o próximo processo.

Máquina de resfriamento

O transportador de resfriamento é instalado com ventiladores soprando vento para batatas fritas. Portanto, a temperatura da superfície cai compartilhada por um vento forte natural. Este é um processo importante antes do processo de congelamento rápido.

E a placa de recebimento de óleo sob o transportador de resfriamento é opcional para receber óleo caído de batatas fritas.

Fries Freezer Tunnel Freezers IQF Freezers

Frias francesas Freezer Quick é aplicável a congelar grandes quantidades de batatas fritas em curtos períodos de tempo sem causar nenhum grupo de desenvolver ou ter o produto grudando juntos.

Temperatura central do material para alimentar:<20 C

Temperatura de descarga: -18℃

Tempo de congelamento: 15 min a 45 minutos.

Embalando máquina automática com pesagem, Recheio e fabricação de bolsas

Para embalar batatas fritas congeladas em sacola plástica automaticamente, A máquina automática de enchimento e vedação da bolsa é a escolha ideal. Inclui elevador, Pesar de várias cabeças, flatform, Dispositivos de fabricação de bolsas com função de impressão de data, e um transportador de produto final.

O que é mais, A máquina de embalagem de chips tem vantagem de alta eficiência, pesagem precisa, e trabalhando contínuo com a linha de processamento de batatas fritas.

Parâmetro da linha de processamento de batatas fritas

Lista de máquinas de batatas fritas francesas congeladas como abaixo apenas para referência. E somos capazes de personalizar a linha de processamento de batatas fritas com base no layout de fábrica de clientes, tensão, Variedades finais de produtos, Tipo de embalagem etc..

| Não. | Nome da máquina | Quantidade | Unidade | Taxa de tensão |

| 1 | Elevador | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 2 | Máquina de lavagem e descascamento de batata | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 3 | Selecione a correia transportadora | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 4 | Cortador de batata | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 5 | Elevador de spray de balde | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 6 | Máquina de colheita de frituras francesas não qualificadas | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 7 | Máquina de enxágue | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 8 | Máquina de branqueamento | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 9 | Desidratador de vibração | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 10 | Secador resfriado a ar | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 11 | Elevador | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 12 | Máquina de fritar contínua | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 13 | Máquina vibradora de Deoilingg | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 14 | Secador resfriado a ar | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 15 | Máquina de espalhamento de batatas fritas | Definir | 380V 50Hz 3ph pode ser personalizado | |

| 16 | Freezer | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

| 17 | Máquina de embalagem | 1 | Definir | 380V 50Hz 3ph pode ser personalizado |

Batatas fritas que fabricam fábrica de máquinas

Vantagem

Fábrica completa de máquinas para alimentos

30 anos R&História D

Desempenho estável de máquinas

Entrega no prazo

Garantia

12 Meses de Garantia de Qualidade

Suporte técnico vitalício e serviço de peças de reposição

Serviço

Suporte pós-venda em operação, manutenção.

Treinamento gratuito on-line ou off-line na fábrica

Instalação no local na fábrica do cliente

Consultoria geral de negócios para novo planejador de negócios.

Serviços de entrega para o país do comprador

Preço da máquina de batatas fritas

Temos uma equipe profissional de engenheiros técnicos e uma equipe de desenvolvimento de produtos para atualizar nossa linha de produção para maior eficiência, menos produção e melhor satisfação do usuário. Além do mais, entendemos e respondemos rapidamente às necessidades dos clientes com a solução certa para seus negócios.

Você é mais bem -vindo para entrar em contato com nossa equipe agora para obter um custo da fábrica de batatas fritas..

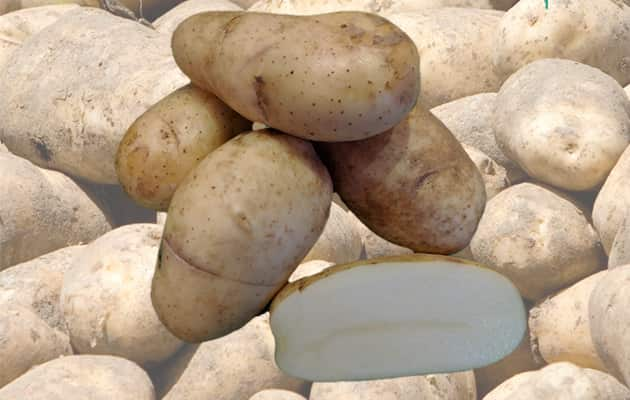

Qual é a melhor batata usada para a linha de batatas fritas congeladas?

Shepody é uma cultivar de batata de pele branca que se originou em New Brunswick, Canadá e é usado para ferver, cozimento, e fritura francesa. É dRy matéria 19-21%, baixo teor de açúcar reduzido ≤ 0.4% , especialmente adequado para o processamento de frita.

O que é mais, Batatas fritas em restaurantes de fast food e batatas fritas em supermercados são produzidos em massa em fábricas. O bem em forma, Shepody de olhos claros é fácil de descascar durante a produção, e as batatas fritas e batatas fritas resultantes raramente mostrando buracos e cicatrizes.

Portanto, Shepody são tipos de batata ideais para produção de batatas fritas congeladas.

Máquinas Relacionadas

Máquinas de batatas fritas, linha de produção de chips de banana, linha de fritura de penautas. fritadeira contínua, Linha de produção de batatas fritas em pequena escala