Máquina automática de batatas fritas de batatas fritas de batatas fritas

Linha de produção automática de batatas fritas é adaptado para atender à crescente demanda por alta qualidade, consistente, e deliciosas batatas fritas.

Máquina de batatas fritas de batata é aplicável em fábricas de processamento de alimentos, que requer grandes quantidades de uniforme, batatas fritas de alta qualidade de forma rápida e eficiente.

Aplicativo: batata frita, batatas fritas, e outros lanches semelhantes.

Material: Aço inoxidável de qualidade alimentar 304

Capacidade: 100kg por hora, 200kg por hora, até 300 kg/h e capacidade personalizada disponível

Aplicação automática da linha de produção de batatas fritas

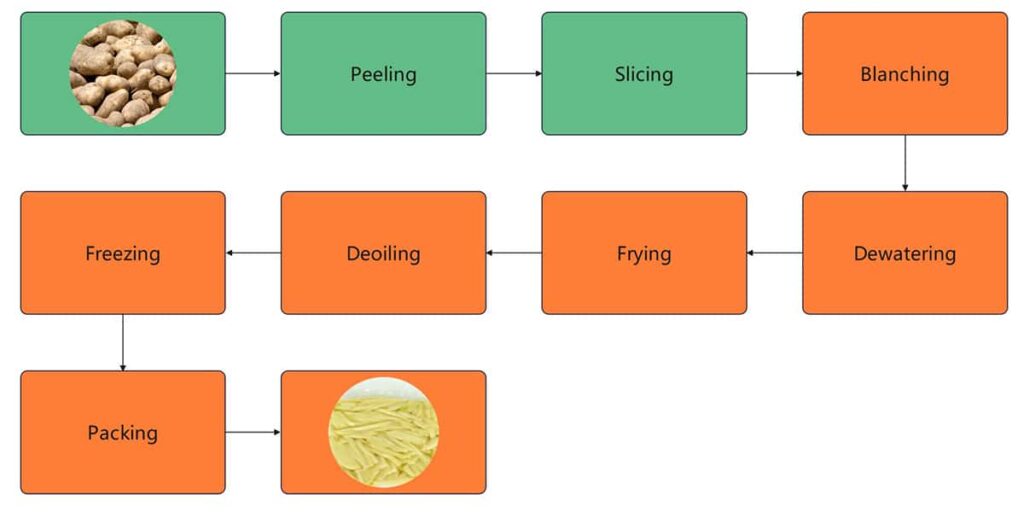

A linha de produção de batatas fritas usa as batatas com baixa taxa de água e alto teor de amido como matérias -primas, E através da lavagem, peeling, fatiar, processo de fritura, Processo de empacotamento rápido de freezer e aspirador, A linha de batatas fritas transforma a batata crua em deliciosas batatas fritas de batata.

A linha de produção de batatas fritas de batata oferece uma solução versátil para gigante de fast food, dono de um restaurante, ou um fabricante de alimentos. E a linha de produção de batatas fritas congeladas é flexível para fazer várias batatas fritas, como chips de banana, chips de batata doce, batatas fritas, Fritas francesas congeladas etc.

Introdução automática de produção de batatas fritas congeladas

Descrição automática da linha de produção de batatas fritas

Nossa linha de produção automática de batatas fritas congeladas é uma solução completa para produzir grandes volumes de produtos congelados e fritos, como batatas fritas, batatas fritas, e outros lanches semelhantes. E esta planta de processamento de batatas fritas está equipada com uma variedade de máquinas que garantem alta automação, Simplicidade em operação, e economia de energia significativa.

E esta linha automática de processamento de batatas fritas começa com a máquina de lavar e descascar, seguido de máquina de fatiar, máquina de branqueamento para batatas, pote redondo Máquina de fritura profunda, Máquina de Dealing Tipo de descarga inferior, Freezer rápido e finalmente máquina de embalagem. Cada máquina é cuidadosamente projetada para maximizar a saída, mantendo os padrões da mais alta qualidade. Além do mais, Os materiais de qualidade alimentar e a tecnologia avançada garantem que a linha de batatas fritas atenda a todos os regulamentos de saúde e segurança.

Especificação automática da linha de produção de batatas fritas

Aquecimento Método: Aquecimento elétrico / Aquecimento a Gás

Materiais da Máquina: Qualidade alimentar 304 materiais de aço inoxidável, melhor qualidade feita

Capacidade: 100kg por hora a 300 kg por hora, personalizável

Recomendação: Tempo de branqueamento: 60 para 90 segundos à temperatura da água: 90 a 95℃. Enquanto, hora de fritar: 60s na temperatura de fritura de óleo: 185℃. Congelando 30 para 50 minutos por lote -30 ~ -35c;

Tamanho de Fries Frech: 7*7mm a 12912mm ajustável.

Pacote: Pacote Vaccum, pacote de plástico etc..

Requisito de espaço de fábrica: Podemos personalizar a linha de produção com base no tamanho da fábrica e na planta baixa

Gráfico de produção de batatas fritas

Vantagem da linha de batatas fritas

Maior eficiência:

Uma linha de produção automática de batatas fritas pode aumentar significativamente sua capacidade de produção. Com tarefas automatizadas de manuseio de máquinas, como fatiar, branqueado, congelando, e embalagem, Você pode produzir um maior volume de batatas fritas congeladas em um período mais curto. Isso pode levar ao aumento das vendas e lucratividade para o seu negócio.Qualidade consistente do produto:

Máquinas de batatas fritas automatizadas garantem qualidade consistente do produto. A máquina de batata cortou as batatas para a espessura uniforme, Máquina de branqueamento para cozinhar o bastão de batata com a temperatura perfeita, e máquina de fritura de batata com fritura estável, e freezer rápido para congelar batatas fritas a uma taxa consistente. Como resultado, As batatas fritas congeladas da Ffinal que são uniformes de tamanho, forma, e textura, Aprimorando a satisfação do cliente e as compras repetidas.Custos de mão -de -obra reduzidos:

A linha de produção automática de batatas fritas congeladas pode reduzir o número de funcionários necessários para operar as máquinas. Como um retentl, Pode diminuir seus custos de mão -de -obra. Adicionalmente, Máquinas de batata automatizadas podem funcionar continuamente sem precisar de intervalos, Aumentando ainda mais sua produtividade.Segurança aprimorada:

As máquinas de batatas fritas automatizadas reduzem o risco de lesões no local de trabalho. Com menos funcionários necessários para lidar com máquinas e materiais, A probabilidade de acidentes diminuiu significativamente. Isso pode levar a custos de seguro mais baixos e menos lesões no local de trabalho, Criando um ambiente de trabalho mais seguro e produtivo.

Recursos de linha de batatas fritas

Preço da máquina de lavagem e descamação de batata

A máquina de lavar e descascar é feita de aço inoxidável de grau alimentar 304. Que garantem uso durável e segurança alimentar.

Os rolos de nylon de alta qualidade descascaram a pele da batata. Além do mais, Os materiais do rolo podem ser personalizados para serem adequados em diferentes raízes, como cenouras, mandioca etc..

A lavadora de batatas e a máquina descascadora remove a batata suja durante o processo de descascamento. E é simples de executar e limpar a máquina.

E a máquina de descasque de lavagem de batatas tem seu próprio sistema de controle de partida e desativação, que permite ao trabalhador ajustar o tempo de descascamento para diferentes materiais.

Máquina de cortador de batatas fritas

O cortador automático de batatas fritas é adequado para cortar batata em fatias de 7 mm a 12mm. E o cortador de batatas fritas de batata pode usar para cortar chips de banana, chips de batata doce, anéis de cebola e outras raízes.

Por este cortador elétrico de frita francesa, O tamanho do bastão de batata é uniforme e menos desperdício.

Máquina de fritura de batatas fritas

Este é um pote redondo fritadeira em lote com a tremonha de alimentação, e função de mistura, e função de materiais de descarga. Portanto, Melhora muito a eficiência e reduz a mão -de -obra na máquina de produção de batatas fritas.

E o tempo e a temperatura de fritura são controláveis e ajustáveis com base nas necessidades.

Método de aquecimento: Máquina de fritura elétrica de fritadeira e aquecimento a gás disponível para o cliente escolher.

Máquina centrífuga de desengorduramento

Frias francesas que usam o Princípio Centrigugal para remover o óleo em batatas fritas depois de fritar. Portanto, As batatas fritas fritas não são oleosas e com melhor gosto e têm vida útil longa.

Durante o processo de fiação de alta velocidade, Ele não apenas tira muito óleo, mas também esfria a temperatura das batatas fritas também.

Depois de destacar, Os palitos de batata são descarregados do fundo, que haverá um elavador para enviá -los para o próximo estágio.

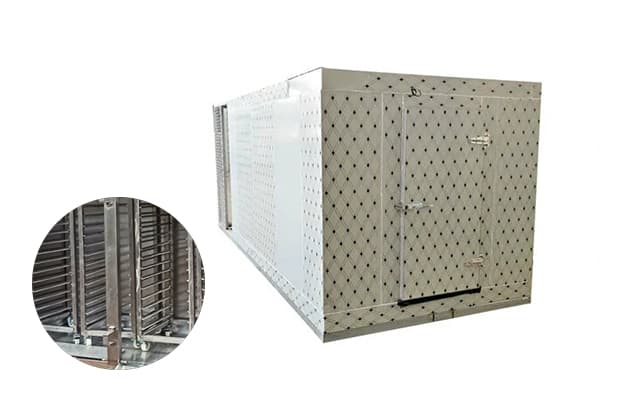

Frie Fries Freezer

O freezer de batatas fritas é congelar as batatas fritas em -30 ~ -35 ℃ temperatura em cerca de 30 para 50 minutos, Até a temperatura central-18 ℃.

Este é o freezer do tipo lote para fábricas de batatas fritas pequenas e de média capacidade.

Máquina de embalagem para chips

Temos uma máquina de embalagem de vácuo de câmara única e selador de vácuo de câmara dupla, de acordo com o tamanho da embalagem e o requisito de capacidade.

Pode ser usado para fazer pacote de vácuo para batatas fritas, alho, Fatias de batata fresca, cenouras etc..

Parâmetro de produção de batatas fritas congeladas

Como fabricantes profissionais de linhas de produção de batatas fritas, Personalizamos nossa linha de produção de batata congelada para atender ao tamanho dos negócios. Aqui está os nossos dados automáticos de linha de produção de batatas fritas congeladas e somos capazes de personalizar Linha de produção de batatas fritas totalmente automática de batatas fritas.

| Modelo | DT-FF-100 | DT-FF-200 | DT-FF-200 |

| Entrada Bruta | 200KG | 400KG | 600KG |

| Saída de chips | 100KG | 200KG | 300KG |

| Tensão | 380V / 220V | ||

Fabricantes de linhas de produção de batatas fritas

Vantagem

Fábrica completa de máquinas para alimentos

30 anos R&História D

Desempenho estável de máquinas

Entrega no prazo

Garantia

12 Meses de Garantia de Qualidade

Suporte técnico vitalício e serviço de peças de reposição

Serviço

Suporte pós-venda em operação, manutenção.

Treinamento gratuito on-line ou off-line na fábrica

Instalação no local na fábrica do cliente

Consultoria geral de negócios para novo planejador de negócios.

Serviços de entrega para o país do comprador

Linha de produção de batatas fritas para venda

O custo de uma linha de produção automática de batatas fritas congeladas pode variar dependendo do tamanho e da complexidade das máquinas. É importante definir um orçamento antes de iniciar sua busca pela linha de produção perfeita. Considere suas necessidades de produção, custos de mão -de -obra, e ganhos potenciais de lucro para determinar o melhor investimento para o seu negócio.

Oferecemos preços competitivos para nossa linha automática de produção de batatas fritas congeladas, com opções para personalizar as máquinas para suas necessidades específicas. Entre em contato conosco hoje para uma cotação detalhada e para saber mais sobre nossos produtos e serviços.

Máquinas Relacionadas

Linha de produção de batatas fritas totalmente automática, Mini Planta de batata, linha de produção de chips de banana, linha de fritura de penautas. fritadeira contínua, fritadeira tipo cesta, fritadeira automática de panela redonda, máquina de fritar contínua.