Macaroni Line Pasta Maker Spaghetti Machine Maker

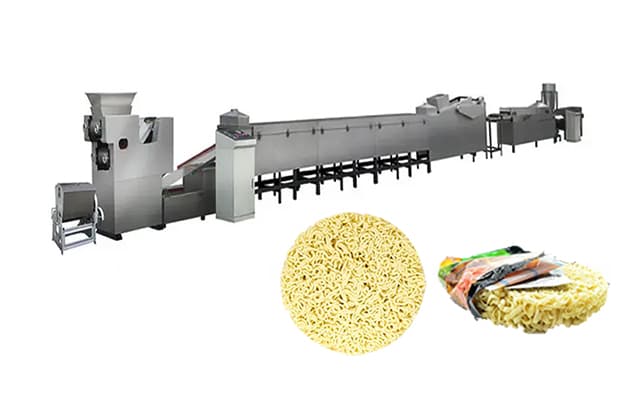

Macaroni line is ideal for manufacturing various types of short-cut pasta, including macaroni, penne, fusilli, and more.The whole set includes dough mixer, extruding machine, cutter, shifter, drying machine, cooling conveyor and packing machine.

Raw Material: potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials.

Capacity: 100 to 120 kg/h & 250-300 kg/h

Macaroni Pasta Production Line Application

Macaroni Line is ideal for manufacturing various types of short-cut pasta, including macaroni, penne, fusilli, and more. And it is suitable for both fresh and dried pasta production. By changing different molds, it can also make shell scrip, Orecchiette, the tremella crisp, five-star crisp, rice crust, lanterns , conch, peanut type, big and small empty tubes of different shapes.

Besides, this line can be customized to meet specific production requirements and capacity needs. And with its advanced technology and manufacturing process, it ensures consistent pasta quality, shape, and texture.

Macaroni Maker Introduction

Macaroni Line Description

Pasta macaroni noodle is a beloved traditional Italian cuisine which has been a staple food enjoyed worldwide. DT food machine, a leading provider of pasta production solutions, offers comprehensive pasta noodle production lines, customized for a wide range pasta macaroni noodles shapes and sizes. And our pasta macaroni production line is designed to meet the demands of both small-scale and large-scale pasta manufacturers, ensuring high-quality output with minimal effort and low production cost.

Macaroni Pasta Making Machine Specification

Heating Method: Electric heating

Machine Materials: Stainless streel materials

Capacity: 100 to 120 kg/h & 250-300 kg/h

Voltage: 380V 50HZ 3PH, customized voltage available.

Macaroni Production Line Flow Chart

The complete production flow on macaroni production line is from mixing to extrusion, cutting, drying, cooling, and packing. The automatic macaroni line ensures a seamless production process, minimizing waste and maximizing output.

Macaroni Pasta Machine Features

Rational Design and High Automation

The pasta macaroni production line boasts a rational design that maximizes efficiency and minimizes downtime. Its high degree of automation allows for seamless operation, reducing the need for manual intervention and enhancing productivity.

Stainless Steel Construction

The main body of the production line is constructed from stainless steel, ensuring durability and ease of cleaning. This material is resistant to corrosion and maintains hygiene standards, crucial for food production environments.

Wear-Resistant Screws

The screws used in the extrusion stage are made from 38CrMnAl, a wear-resistant material that ensures long-lasting performance and minimal maintenance.

Adjustable Temperature and Rotating Speed

Adjustable Temperature and Rotating Speed: The production line features adjustable temperature and rotating speed settings, allowing you to fine-tune the production process to achieve optimal pasta quality.

Automatic macaroni making machine Parameter

| Model | Power | Capacity | Line Size |

| DT100 | 130kw | 100-120kg/h | 25*3*3m |

| DT250 | 230kw | 250-300kg/h | 35*4*4m |

1. Dough Mixer

It is used to mix ingredients.

Power:4kw

Dimension(m):1.1*0.8*1.2

2. Screw Elevator

After mixing the wheat flour, the scew elevator feed the dough to hopper on extuder .

Power:1.1kw

Dimension(m):1.7*0.6*2.2

3. Extruder

It extudes the pasta macaroni noodle.

Model DT100

Total Power:95kw

Dimension:3.2*0.9*1.9m

3. Cutter

When dough is extruded in circular tube, then pull the circular tube into the shaping machine for cooling ,rolling and cutting it into shorter tubes.

Total Power:1.5kw

Dimension(m):1.7*1*1.5

4. Vibrating Shifter

The vibrating machine separate the pasta noodles before drying.

Capacity: 3kva

Dimension:1.5×1×0.5m

5. Dryer Oven

Drying Oven for Dewatering

Dimension: 3.5*1.1*2.1 & 5.4*1.3*1.8M

Power: 43.5KW

Dryer Oven for Drying

Dimension: 4.0*1.1*2.1m & 8.4*1.3*2.2m

Power: 83.5 kW

6. Cooling Conveyor

Cooling conveyor cools down the macaroni noodle before packing.

Dimension: 5.2*0.8*1.4m

Power: 1kw

7. Packing Machine

To pack macaroni into plastic bag automatically, the automatic macaroni packing machine is ideal choice. It include elevator, multi-head weigher, flatform, bag making devices with date printing function, and an end product conveyor.

The model of packing machine is advised based on package dimension and weight.

Macaroni Maker Manufacturer

Advantage

DT food machine offers a turn-key solution, including equipment installation, debugging, and operator training. Our engineers will visit your factory to ensure that the production line is running smoothly before handing it over to your team.

Guarantee

12 Months Quality Guarantee

Whole life technical support and spare part service

Service

After-sale support in operation, maintenance.

Free Training on line or off line at factory

Onsite installation in Customer’s factory

Overall business advises for new business planner.

Delivery services to buyer’s country

Pasta Making Machine Price

DT food machine’s pasta macaroni production line offers a comprehensive solution for pasta manufacturers looking to enhance their production capabilities. With its advanced technology, high automation, and customizable features, our pasta noodle lines become the cornerstone of your pasta production operations.

Welcome to contact our team for a professional business proposal and production solution now.

Related Machines

Instant noodle line, pasta maker, stick noodle machine, dough mixer, automatic noodle packing machine.