Waffle Roll Maker Egg Roll Biscuit Making Machine Barquillos Maker Machine for Sale

Waffle roll maker is a specialized piece of equipment designed for the commercial production of crispy, golden-brown waffle rolls, waffle chips, egg roll biscuits, Kuih Kapit, barquillos and similar treats.

Automatic egg roll biscuit making machine is applicable in busy restaurants, bakeries, and food trucks, food distributors and snack shops, offering unparalleled efficiency, versatility, and quality.

Heating Method: Gas heating or Electric Heating

Voltage: 380V /220V 50HZ or depending on your region

Capacity: 300 pieces an hour to 1200 pieces an hour

Waffle Roll Maker Description

Waffle roll maker is a specialized piece of equipment designed for the commercial production of waffle rolls, egg roll biscuits, Kuih Kapit, Pizzelle, and similar treats. Unlike home-use models, these best waffle roll makers are built to withstand the rigors of continuous, heavy-duty use. And they are constructed from high-quality materials such as stainless steel and feature advanced technology to ensure consistent, high-quality output.

Waffle Roll Maker / Egg Roll Biscuit Making Machine is available in various sizes and configurations to suit different production needs. Regardless of the specific design, waffle roll maker commercial is engineered to produce crispy, golden-brown waffle rolls that are sure to delight your customers.

Waffle Roll Maker Application

The versatility of waffle roll maker commercial makes them an essential addition to any commercial kitchen. Here are some of the many applications for these machines:

- Ice cream shops and Bakeries: Use waffle roll makers to create unique menu items, such as stuffed waffle rolls, waffle chips, and dessert waffle cones.

- Food Trucks and Catering:

Create custom waffle rolls with various fillings and toppings to cater to diverse tastes and preferences.

- Retail and Wholesale:

Produce large batches of waffle rolls for sale in retail stores or to wholesale customers.

Offer bulk discounts and customize packaging to meet the needs of your clients.

- Snack Bars and Convenience Stores:

Offer a variety of flavors and toppings to keep customers coming back for more.

Egg Roll Biscuit Making Machine Specification

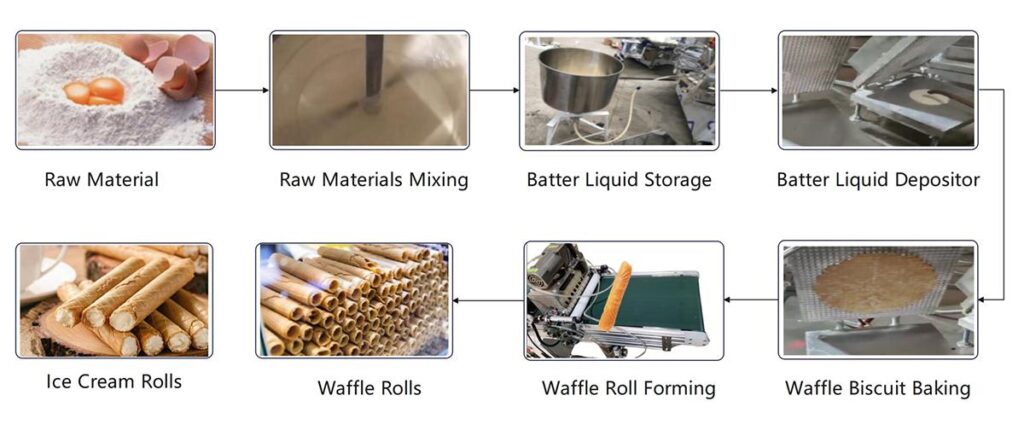

Crispy egg roll maker machine includes grouting machine, baking machine, and forming machine.

Model: Egg Roll Biscuit Machine DT Series

Capacity: 300 to1200pieces an hour

Price: Best Price, direct supply from factory with highest quality

Heating Source: Electric heating /Gas ( LNG or LPG )

Voltage: 380V /220V 50HZ or depending on your region

Material: Machine cover stainless steel, supporting frame carbon steel, baking plate cast iron or steel

More on waffle roll maker commercial

Capacity: 300 pieces per hou, 600 pieces per hour, 800 pieces per hour, 1200pieces per hour.

(Kindly note that the above capacity range is for reference, and even on same model of machine, the final capacity could be slightly different due to the skill level of the worker’s operation, the size of the cone, etc)

Certifications and Compliance:

ISO, CE to ensure compliance with industry standards and regulations

Automatic Egg Roll Making Machine Working Flow

Barquillos Making Machine and Automatic Egg Roll Machine Specification

DT Food machine company design and produce various models of barguillos making machine and egg roll maker to meet customer demand. For each model, there is gas heating or electric heating baking machine for customer to choose. Here is technical data on commercial electric egg roll machine

Model | DT-6 | DT-9 | DT-12 | DT-15 | DT-18 |

Capacity | 300 to 400 pcs/h | 400 to 600 pcs/h | 600 to 800 pcs/h | 800-1000 pcs/h | 1000-1200pcs/h |

Heating Power | 10kW | 15kW | 19.5kW | 23kW | 28kW |

Dimension | 150*150*125cm | 160*160*125cm | 170*170*125cm | 180*180*125cm | 190*190*125cm |

Waffle Roll Maker Features

- Adjustable Temperature Control:

Look for a machine with adjustable temperature settings to customize the crispiness and color of your waffle rolls.This feature allows you to experiment with different recipes and find the perfect cooking temperature for your specific needs.

- Automatic Injection

Mwholesale egg roll machine features automatic batter injection mechanisms that streamline the production process. And it can continuously produce waffle rolls, saving time and labor costs.

- Safety Features:

Industrial waffle roll makers should include safety features such as temperature control, emergency stop buttons etc.These features help protect operators and ensure safe, efficient production.

Kuih Kapit Maker Egg Roll Waffle Maker Advantage

High-Efficiency:

The process of batter dispensing, biscuit baking, waffle roll shaping is completed on one set of egg roll maker. It is more efficient to use than homemade egg roll making machine without machine. Users could enjoy a better return on investment for the production efficiency, reduced labor costs, and minimized food waste.

Multi-function Possibility

It is common for user to make different products from one set of egg roll biscuit making machine to diversity their supply and also save investment cost. As a professional waffle roll and egg roll machine manufacturer, we make it possible for our user to make all in one machine, such as waffle cone, sugar cone, egg roll, bowl cup, pizzelle, Kuih Kapit waffle cookies etc. by changing the shaping machine.

Friendly note, it is important for our user to talk with our team, sharing the end product design, size and shape to get a final solution.

Heating Source according to Customer Requirement

The heating power is one key factor for production cost. Therefore, we design two type of heating method available for customer to choose based on their local power cost.

However, in some regions, many new users plan to set up business at home without industrial power supply. It will not be a problem for them at all, since they have the gas heating ice cream cone maker which can be customized into home waffle cone maker.

User Friendly

The ice cream waffle roll maker is very friendly to user without technical background or machine operation experience. It requires one operator to pick up ready baked waffle biscuit and put it on waffle roll shaper which we also called waffle rolling machine. Quite simple and safe to operate.

Waffle Roll Maker How to Use ?

Regardless of the specific model you choose, it’s important to familiarize yourself with the operating instructions for your commercial waffle roll maker.

Refer to the user manual for detailed information on setup, operation, and maintenance. With proper care and maintenance, your machine will provide years of reliable service.

Here is brief steps to follow:

- Position the full set of waffle roll making machine on flat ground. Adjust anchor bolts to lift the casters off the ground.

- Connect air source from air compressor to forming machine or called Rolling Machine and grouting batter tank, and baking machine.

- Plug egg roll forming machine, batter grouting batter tank to the biscuit baking machine.

- Connect the baking machine to factory power cord;Position the batter nozzle from grouting machine in middle of baking plate.

- Turn on baking machine. (Baking time and baking temperature is preset before delivery, but it is adjustable at user site based on their product need.

- After production, plug off each machine, and cut off electricity. Clean baking machine, forming machine and grouting batter tank according to User’s Book.

Best Waffle Roll Maker Manufacturer

Durable and Stable

The machine is designed for contineously working 8hrs per shift. But customer could extend production period based on their market order. And it produces the ice cream waffle roll with uniform color and consistant sizes. The cone quallity is good and help our customer gain more market reputation and brand effect.

Guranteed quality and Service

The quality made waffle roll machines increase the production capacity and customer pay less maintenance cost.

Besides, we offer 12 months quality guarantee, installation guide and service and whole life technical support, and whole life spare part supply.

More Value to Customer

DT food machine offers complete solution from your order of machine, delivery , installation, waffle cone recipes to you to help your food business startup and succeed.

Besides, we do tailor made business for our customer,to meet their customized quirement on the end product shape, size and patten or logo design. We also accept OEM and ODM production for our machine distributors.

Barquillos Maker Machine for Sale

Waffle roll machine price is fixed within a period if customer make the waffle roll, standard size without special design. Please contact our team for standard waffle roll egg roll machine price list now.

While, for customer who prefer customized waffle roll design, logo or patterns, or even voltage customized on machine, please talk to our team about your detailed requirement and we will offer you the solution to your design and present customized cost on standard machine cost.

What are waffle rolls made of ?

The waffle rolls is crispy and sweet. The ingredients are wheat flour, sugar, edible oil, salt, and water etc. We will provide you basic recipe ratio after order and you can add your secret ingredients to have special flavor and taste.

Related Machines

Automatic ice cream cone production line, wafer cone maker, batter mixer, air compressor 4KW