Waffle Cone and Bowl Maker Waffle Cup Maker

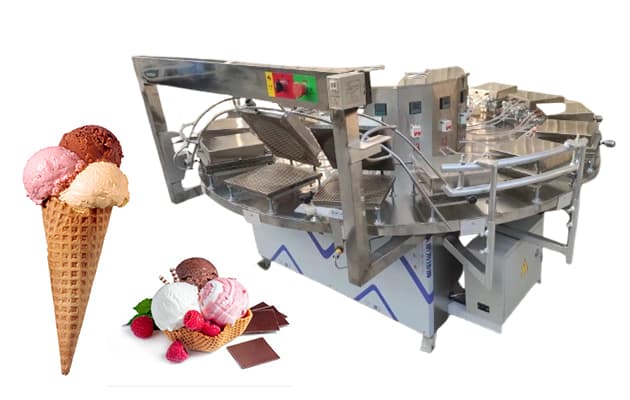

Waffle cone and bowl maker is a versatile and efficient ice cream cone making machine, designed to make crispy, golden brown sugar cones and waffle cups. And it can also make waffle rolls, pizzelle, kuih kapit etc

Depending on the model, the ice cream cup maker can be powered by electricity heating or gas heating, catering to commercial use with output ranging from 100 pieces an hour to 1200 pieces an hour.

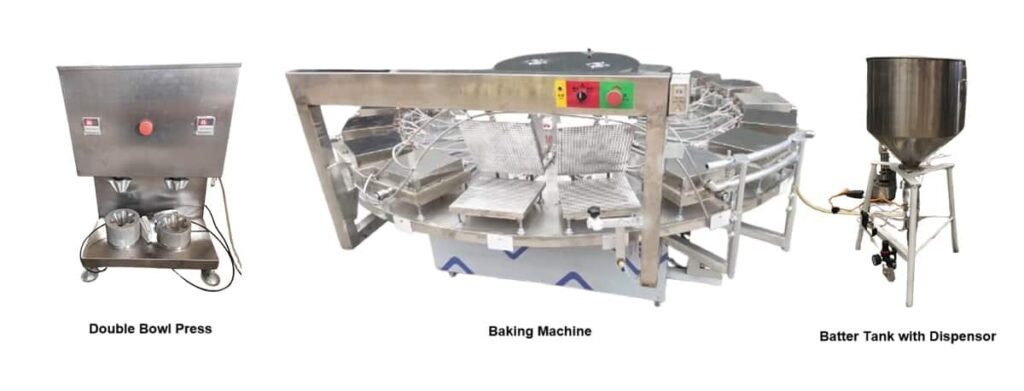

Waffle cup maker includes: Batter tank with dispensor, baking machine, waffle bowl press

Voltage: 380V 50HZ 3ph or customized

Materials: stainless steel material cover

Waffle Cone and Bowl Maker Application

Waffle cup machine is versatile and efficient in making crispy, golden brown ice cream cups and cone. Due to the economical cost, user friendly, saving energy, and higher capacity, this commercial waffle bowl maker is excellent investment for various businesses and individuals such as ice cream shops, ice cream cone vendors and ice cream factory.

And commercial waffle cup maker makes waffle bowl at uniform shape, bright color at fast speed and little labor. Besides, by adding cone rolling machine, the waffle cone maker can also make ice cream cones. Similarly, it can also make waffle rolls by adding egg roll rolling machine. What is more, the waffle biscuit baking machine can also make waffle biscuits, Italian pizzelles and Kuih Kapit etc. In a word, this waffle cone and bowl maker machine has multi-function and popular and greatly improve production efficiency than their tradtional handmade ice cream cones.

Bowl Shaped Waffle Maker Introduction

Waffle Bowl Maker Description

Waffle cone and bowl maker is one of professional ice cream cone machine. And it allows ice cream waffle cone suppliers with higher quality waffle cones and waffle bowls at amazing output. Therefore, to meet up increasing market demand and expand business. Besides, by changing the rolling and forming machine, the machine can produce waffle bowls, egg rolls, crispy cones etc. Therefore, one waffle and waffle cone making machine is favorite choice for new business starter or those who plan to update the ice cream cone production.

While, waffle cup machine models with output ranging from 100 pieces an hour to 1200 pieces an hour. Besides, there is gas heating waffle cup machine and electric heating waffle cup making machine to choose. And, normally, the complete set of automatic waffle bowl making machine includes a batter storage tank with auto dispensor, a gas heating baking machine or electric heating baking machine for waffle biscuit, and a double waffle press machine for waffle cups.

There are related machines for customer to choose. A batter mixer 60L will help customer to prepare batter paste in more efficient way. A egg roll rolling machine is necessory to make egg rolls. And a cone rolling machine will be needed to make waffle cones.

The condition for a customer to install the ice cream cup machine, is that their workshop shall be equiped with industrial three phases electricity and air source (4KW air compressor is recommended) and gas source (gas is needed if customer prefer gas heating baking machine) And there will be one to two workers for whole ice cream cone and ice cream cup production from raw material preparation to machine operation and package.

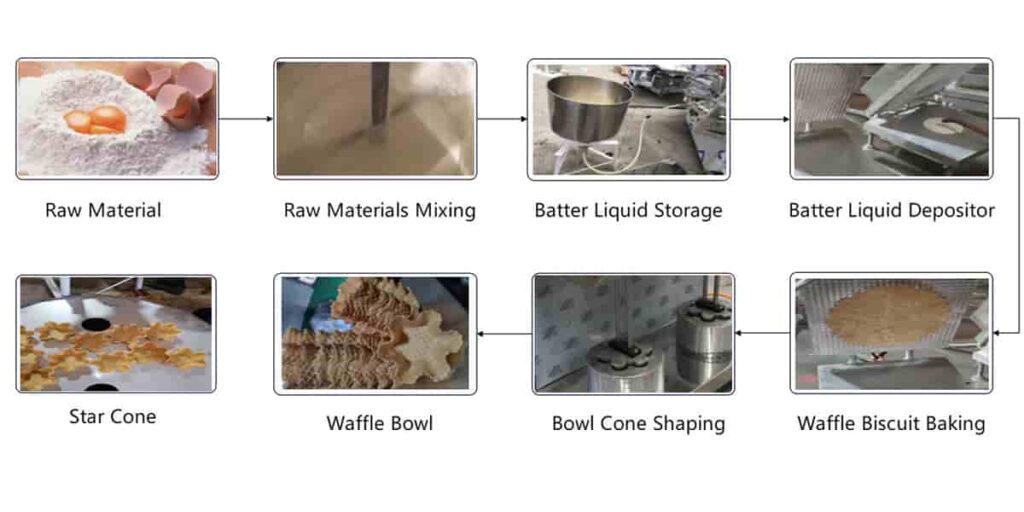

Waffle Bowl Maker Production Process

To make crispy waffle cups, the waffle cup making machine is designed based on the waffle cup production process.

- Raw materials: Wheat flour, sugar, water etc preparation

- Well mix all raw materials at good ratio which is essential to quality waffle biscuit

- Keep the well mixed batter liquid in storage tank and deposit the set amount of batter to baking.

- Baking process requires accurate temperature control and setting for making uniform cones with bright color.

- After waffle biscuit is baked well, quickly put it on bowl press machine when waffle biscuit is still soft.

- Measuring the waffle bowl to make sure the size is what you need, and then pack them into cartons.

Waffle Cup Maker Specification

Model: Waffle cone maker

Capacity:1000 to 1200pcs/h

Price: Best Price, direct supply from factory with highest quality

Heating Source: Electric heating or gas heating (energy for baking machine)

Voltage: 380V 50HZ three phase or customized Voltage

Machine Material: For commercial waffle cone maker, the supporting frame and machine cover shield is made of Stainless Steel 201 by standard. It is for food safety and easy clean purposes.

Waffle Bowl Maker Parameter

Model | DT-6 | DT-9 | DT-12 | DT-15 | DT-18 |

Capacity | 300 to 400 pcs/h | 400 to 600 pcs/h | 600 to 800 pcs/h | 800-1000 pcs/h | 1000-1300pcs/h |

Heating Power | 10kW | 15kW | 19.5kW | 23kW | 28kW |

Dimension | 150*150*125cm | 160*160*125cm | 170*170*125cm | 180*180*125cm | 190*190*125cm |

Best Waffle Bowl Maker Features

Waffle biscuit baking machine

Batter Tank with Dispensor

There are gas waffle biscuit baking machine and electric heating baking machine to choose.

Separate heating control on each baking plates.

Batter paste amount is adjustable to achieve required biscuit size. The machine has the automatic dipensor to deposit the fixed amount to baking machine

waffle cone maker roller

waffle bowl press

The rolling machine has two roller to compete the capacity of baking machine.Making more than one size of cones, the two roller spare part needs to be replaced to match the cone size.

Worker remove waffle biscuit from baking machine and put it on waffle cup making machine to make waffle bowl, star waffle etc.

It has two bowl forming machine to meet capacity of baking machine

Batter Mixer

Industrial Piston Air Compressor 4kW

Batter mixer is to mix all ingredients together into batter paste. It is optional tool to prepare the batter paste. The tank volume is 60L.

Air compressor is needed to support the waffle cone maker. And customer shall have it ready and suggested Model V-0.6/8, Air volume 0.6cbm/min, Volume 115L, Power: 4KW, Voltage 380V

Commercial Waffle Bowl Maker Advantage

Consistency and Quality

The sugar cone maker give consisitant heating to waffle biscuit baking, which ensures the golden-brown color, consistent texture and flavor. This is especially beneficial for businesses that rely on repeat customers and need to maintain a high level of quality.

Efficiency

Waffle cone making machine requires one worker to receive waffle biscuit and put it on rolling machine within 2seconds. It reduces a lot labor and ensure higher output.

Versatility

In addition to sugar cones, waffle cone and bowl maker also be used to make waffle cones, sugar cones, waffle bowls, waffle biscuit etc which offers versatility and expanding your product offerings.

Customizability

Commercial cone maker can realize logo on waffle cones by customize the baking molds. This is to help customer to influence market with their own brand.

Besides, to make more than one sugar cones in one machine, customer may get addtional rolling machines or they can only get addtional rolling spare parts to replace when they need switch between cone sizes.

Waffle Cone Bowl Maker how to use?

The wafer bowl making machine is simple to use. However, each operator shall read and follow the Machine Operation Book which we provide for each order. Here is brief steps to follow:

- Position all the machines on flat ground. Adjust anchor bolts to lift the casters off the ground.

- Connect air source from air compressor to forming machine or called Rolling Machine and grouting batter tank or called batter storage tank.

- Plug cone forming machine, batter grouting batter tank to the biscuit baking machine.

- Connect the baking machine to factory power cord;Position the batter nozzle from grouting machine in middle of baking plate.

- Turn on baking machine. (Baking time and baking temperature is preset before delivery, but it is adjustable at user site based on their product need.

- Put the waffle biscuit on bowl press machine for waffle bowls, or put on cone rolling machine for ice cream cones.

- After production, plug off each machine, and cut off electricity. Clean baking machine, forming machine and grouting batter tank according to User’s Book.

Bowl Shaped Waffle Maker Manufacturer

Durable and Stable

The machine is designed for contineously working 8hrs per shift. But customer could extend production period based on their market order. And it produces the waffle bowls with uniform color and consistant sizes. The cone and bowl quallity is good and help our customer gain more market reputation and brand effect.

Guranteed quality and Service

The quality made waffle cone and bowl machines increase the production capacity and customer pay less maintenance cost.

Besides, we offer 12 months quality guarantee, installation guide and service and whole life technical support, and whole life spare part supply.

More Value to Customer

DT food machine offers complete solution from your order of machine, delivery , installation, waffle cone recipes to you to help your food business startup and succeed.

Besides, we do tailor made business for our customer,to meet their customized quirement on the end product shape, size and patten or logo design. We also accept OEM and ODM production for our machine distributors.

Best Waffle Cone Bowl Maker for Sale

When considering the price of a sugar cone maker, it’s essential to weigh the cost against your production needs and budget.

Our commercial waffle cone and bowl making machine is suitable medium scale business. And for large scale factory production, we have full automatic waffle cone machine.

While, for customer to choose model, it is essential to think about the output that they need, their factory power, the market demand at present and future etc. We love to share experience with you and welcome to contact our team now.

Waffle Cone Bowl Recipe

The waffle cones is crispy and sweet. The ingredients are wheat flour, sugar, edible oil, salt, and water etc. We will provide you basic recipe ratio after order and you can add your secret ingredients to have special flavor and taste.

Related Machines

Automatic ice cream cone production line, wafer cone maker, batter mixer, air compressor 4KW