Mesin Kerepek Kentang Jentera Kentang Kentang Automatik Talian Kerepek Kentang

Mesin kerepek kentang Adakah peralatan pemprosesan kentang dari kentang mentah ke dalam kerepek kentang goreng renyah.

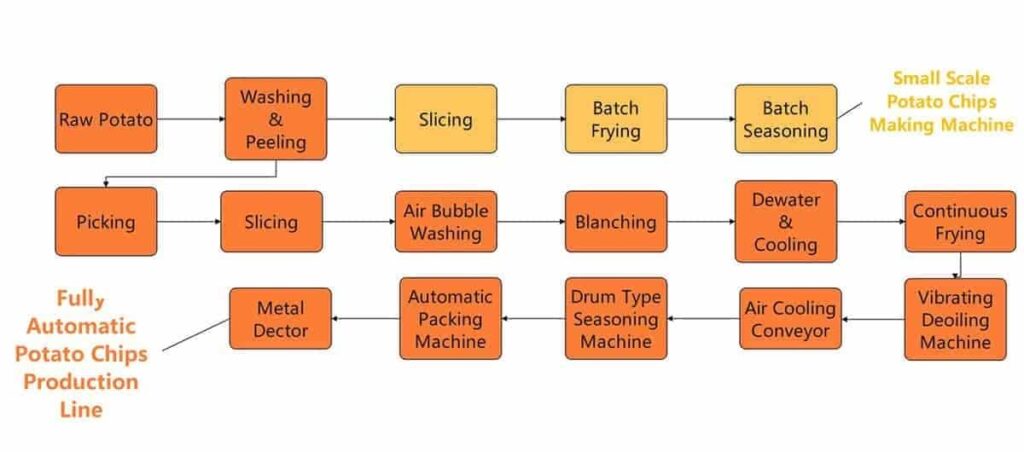

Garis kerepek kentang automatik Mengandungi mesin basuh dan mengelupas kentang, mesin pemotong cip, mesin blanching untuk kentang, mesin penyahairan kentang kentang, Cip kentang menggoreng, mesin deoiling, mesin penyejuk, mesin perasa kentang, mesin pembungkusan kerepek kentang dan peralatan dan fungsinya tambahan untuk menjadikan seluruh baris sepenuhnya automatik dan berfungsi secara berterusan.

Digunakan untuk: Kerepek kentang, kentang goreng, cip plantain dll.

Kapasiti: 50-100kg/j, 100-150kg/j, 200-250kg/j, 350-400kg/j, 450-500kg/j, dan kapasiti yang lebih tinggi.

Aplikasi Mesin Cip Kentang

Mesin kerepek kentang digunakan di kilang kentang kentang dengan loji pemprosesan kentang yang lebih besar atau sederhana. Kerana kecekapan pengeluaran yang tinggi dan makanan kebersihan,Line Chips Potato Automatik Pastikan pelabur dengan kos pengeluaran yang kurang dan lebih banyak bahagian pasaran, oleh itu mendapat pulangan pelaburan yang lebih baik.

Dan, mesin kentang skala kecil membuat mesin baik untuk syarikat pemprosesan makanan yang merancang untuk memulakan perniagaan kecil.

Selain itu, Mesin untuk cip juga boleh menyesuaikan garis untuk membuat cip jari, cip pisang , kerepek kentang manis, dan lain-lain.

Pengenalan Mesin Kentang Kentang

Penerangan pembuat kerepek kentang

Mesin Membuat Kentang Kentang adalah penyelesaian pemprosesan kentang pada mencuci kentang, mengupas, Blanching, menggoreng, perasa dan pembungkusan. Dan garisan cip adalah tinggi kapasiti, Kecekapan super dengan makanan yang berkelayakan dan kebersihan.

Semasa memenuhi permintaan perniagaan yang berbeza, Kami telah merancang garisan pengeluaran kerepek kentang separa automatik dengan kapasiti 20-50kg/h atau 50-100kg/j. Tetapi kami juga merancang cip kentang mesin automatik sepenuhnya dengan kapasiti sehingga 500kg/j dan kapasiti yang lebih tinggi dapat disesuaikan.

Spesifikasi Mesin Pembuat Kentang Kentang

Kaedah Pemanasan: Pemanasan elektrik / Pemanasan Gas

Bahan Mesin: Gred makanan 304 Bahan streel tahan karat, Kualiti terbaik dibuat

Suhu pemanasan minyak: 0℃ hingga 300 ℃ (Fahrenheit 32 ° F ke 572.0 ° f)

Nisbah kentang kentang dan kentang: 4 : 1 untuk rujukan.

Kapasiti: 50Kg/h hingga 500kg/h (Pembuat cip kapasiti yang lebih tinggi dapat disesuaikan)

Keperluan ruang kilang: Kami boleh menyesuaikan barisan pengeluaran berdasarkan saiz kilang dan pelan lantai.

Carta aliran talian pengeluaran kentang

Ciri -ciri barisan pengeluaran cip kentang

Mesin mengupas kentang

Untuk barisan pengeluaran cip skala pusat membeli -belah, bATCH Jenis Mesin Kupas Kentang mempunyai lebih banyak kelebihan mencuci yang cekap dan kadar mengelupas yang lebih tinggi daripada kerja manual.

Dan untuk barisan pengeluaran kerepek kentang automatik sepenuhnya, adalah keperluan untuk mengambil mesin basuh kentang dan mengelupas yang berterusan. Bekerja dengan lif, ia akan menyedari makan kentang mentah yang berterusan, membasuh, proses mengelupas dan pelepasan.

Selain itu, Mesin pengupas jenis sprial menolak foward kentang dan pelepasan dari hujung yang lain untuk memilih tali pinggang penghantar sebelum proses mengiris.

Oleh itu, Mesin pengupas kentang automatik digunakan dalam barisan pengeluaran kerepek kentang yang sederhana dan lebih besar.

Selain itu, ia sesuai untuk mencuci dan mengupas kentang, ubi jalar, ubi kayu, Halia, bawang, wortel dll.

Mesin Slicer Chips

Mesin pemotong kentang boleh memotong kepingan kentang dengan ketebalan. Dan ketebalan kepingan dapat diselaraskan mengikut keperluan.

Selain itu, Terdapat pelbagai model mesin pemotong cip kentang berdasarkan kapasiti dan keperluan pengeluaran.

Blanching kentang sebelum menggoreng

Dalam barisan pengeluaran kerepek kentang automatik dengan kapasiti yang besar, Mesin Blanching memainkan peranan penting untuk melindungi warna cip dan kekal rasa barang.

Cip kentang bercabang adalah kira -kira 5 hingga 15 minit pada suhu air panas 70 ℃ (158.0 ° f)

Terdapat mesin cawangan yang berterusan dengan pemanasan gas dan mesin cawangan berterusan dengan pemanasan elektrik untuk dipilih oleh pelanggan.

Selain itu, Mesin cawangan juga bukan sahaja baik untuk cip kentang bercabang, Tetapi juga kerepek pisang, kentang goreng dan bahan lain.

Mesin penyahairan kentang

Mesin penyejukan udara menghilangkan air dan menyejukkan suhu kerepek kentang bercabang sebelum menggoreng.

Dan mempunyai kesan yang lebih baik, Macine deoiling bergetar adalah keperluan untuk digunakan sebelum pengeringan udara dan penyahairan tali pinggang penghantar.

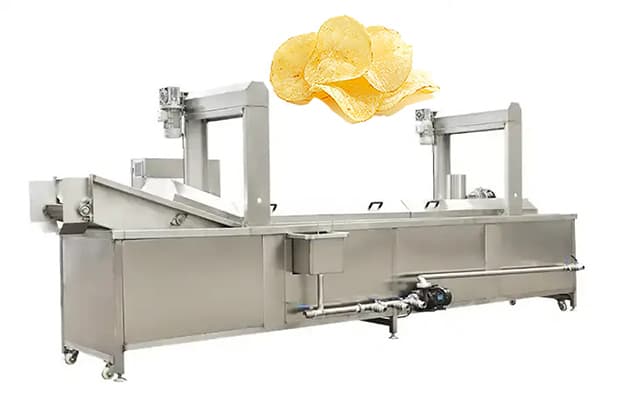

Mesin penggoreng kentang

Untuk kilang kerepek kentang berskala kecil, Garis penggoreng separa automatik adalah pilihan ideal yang mengandungi bulat bulat periuk.

Namun begitu, untuk loji pengeluaran cip automatik, The mesin penggoreng berterusan dikehendaki mengekalkan masa menggoreng yang berterusan bekerja dengan kapasiti yang lebih besar dan kurang tenaga kerja. Dan kerepek goreng perlu berkualiti tinggi dengan warna goreng dan rasa yang baik. Selain itu, sistem isi semula minyak, Sistem Kitar Semula Minyak, Sistem penapisan minyak dan sistem pembersihan diri mesin akan meningkatkan kecekapan pengeluaran, memanjangkan penggunaan minyak dan kerepek berkualiti bettter.

Mesin deoiling

Mesin deoiling bergetar adalah neccessory untuk mengeluarkan minyak pada cip goreng selepas menggoreng.

Kerana, Cip goreng dari garisan menggoreng biasanya membawa beberapa minyak yang menyebabkan produk berminyak dan boleh memoles lantai pengeluaran. Oleh itu, Mesin bergetar dengan plat penerima minyak adalah baik untuk menghilangkan minyak dari permukaan kerepek dan pastikan tapak pengeluaran bersih.

Lebih banyak lagi, Semasa proses bergetar, cip bergerak foward dan tersebar bahkan ke proses seterusnya.

Mesin penyejuk

Penghantar penyejuk dipasang dengan ventilator meniup angin ke cip. Oleh itu suhu cip jatuh secara berkarat oleh angin kuat semula jadi. Ini adalah proses penting sebelum proses perasa dan pembungkusan. Cip penyejukan sepenuhnya akan menjadi lebih cripsy dan mempunyai jangka hayat yang lebih lama.

Reka bentuk pilihan: Net windproof adalah keperluan untuk mengelakkan cip meletupkan tali pinggang penghantar.

Dan plat penerima minyak di bawah penghantar penyejuk adalah pilihan untuk menerima sebarang minyak yang jatuh dari cip.

Mesin perasa cip kentang

Mesin Perasa Jenis Drum Bekerja dengan Perasa Serbuk, Perasa pedas, garam, dan juga boleh disesuaikan dengan penyemburan minyak dll. Menurut keperluan pengeluaran.

Untuk garisan cip, Setelah menyejukkan kerepek, Penghantar adalah keperluan untuk menghantar cip ke drum perasa secara berterusan untuk mencampurkan bumbu dengan kerepek secara merata.

Dan di outlet, Terdapat reka bentuk mesh untuk membolehkan perasa tambahan dan sisa jatuh ke plat penerima. Kerana reka bentuk itu, Cip hanya dengan jumlah perasa yang betul dan rasa yang hebat.

Pembungkusan mesin automatik dengan berat badan, Mengisi dan membuat beg

Untuk mengemas cip ke dalam beg plastik secara automatik, Mesin pembungkusan kerepek automatik adalah pilihan yang ideal. Biasanya, Mesin pembungkusan kerepek automatik hendaklah termasuk lif, penimbang pelbagai kepala, bentuk rata, peranti membuat beg dengan fungsi cetakan tarikh, dan penghantar produk akhir.

Dan, Untuk pembungkusan cip, Fungsi nitrogen adalah keperluan untuk menyimpan cip dengan jangka hayat yang panjang dan memberi perlindungan semasa pengangkutan.

Lebih banyak lagi, Mesin pembungkusan cip mempunyai kelebihan kecekapan tinggi, seberat yang tepat, dan bekerja berterusan dengan barisan pengeluaran cip.

Parameter Mesin Pembuat Kentang Kentang

Barisan pengeluaran kentang automatik sepenuhnya DT-PC-500, kapasiti 450-500kg/h untuk rujukan.

| Nama | Penggunaan kuasa | Kadar voltan |

| Lif dengan bunker | 0.75 kW | 380V 50HZ 3PH, dapat menyesuaikan |

| Mesin basuh kentang dan mengelupas | 4.75 kW | 380V 50HZ 3PH, dapat menyesuaikan |

| Memilih penghantar | 0.75 kW | 380V 50HZ 3PH, dapat menyesuaikan |

| Mesin pemotong cip kentang | 1.1 kW | 380V 50HZ 3PH, dapat menyesuaikan |

| Mesin Blanching | 70 kW | 380V 50HZ 3PH, dapat menyesuaikan |

| Mesin penyahairan bergetar | 1.5KW | 380V 50HZ 3PH, dapat menyesuaikan |

| Garis dehidrasi penyejukan udara | 15 kW | 380V 50HZ 3PH, dapat menyesuaikan |

| Penghantar lif sebelum menggoreng | 0.75 kW | 380V 50HZ 3PH, dapat menyesuaikan |

| Cip kentang menggoreng | 204.5 kW | 380V 50HZ 3PH, dapat menyesuaikan |

| Gegaran mesin deoiling | 1.5 kW | 380V 50HZ 3PH, dapat menyesuaikan |

| Saluran pengeringan penyejukan udara | 8 kW | 380V 50HZ 3PH, dapat menyesuaikan |

| Eelvator ke perasa | 0.75 kW | 380V 50HZ 3PH, dapat menyesuaikan |

| Mesin perasa | 1.5 kW | 380V 50HZ 3PH, dapat menyesuaikan |

| Mesin pembungkusan kentang automatik sepenuhnya | 6.5KW | 380V 50HZ 3PH, dapat menyesuaikan |

Pengeluar talian kerepek kentang

Kelebihan Kilang Mesin Goreng

Kilang jentera makanan sehenti

30 tahun r&D Sejarah

Prestasi jentera yang stabil

Pada masa penghantaran

Jaminan

12 Jaminan Kualiti Bulan

Sokongan teknikal seumur hidup dan perkhidmatan alat ganti

Perkhidmatan

Sokongan selepas jualan dalam operasi, penyelenggaraan.

Latihan Percuma dalam talian atau luar talian di kilang

Pemasangan di tapak di kilang Pelanggan

Keseluruhan nasihat perniagaan untuk perancang perniagaan baharu.

Perkhidmatan penghantaran ke negara pembeli

Harga barisan pengeluaran kentang

Kami mempunyai pasukan jurutera teknikal profesional dan pasukan pembangunan produk untuk mengemas kini barisan pengeluaran kami untuk keberkesanan yang lebih tinggi, kurang pengeluaran dan pengguna yang lebih baik memuaskan. Selain itu, Kami faham dan cepat bertindak balas terhadap keperluan pelanggan dengan penyelesaian yang tepat untuk perniagaan mereka.

Anda sangat dialu -alukan untuk menghubungi pasukan kami sekarang untuk penyelesaian dan petikan menggoreng.

Mesin Berkaitan

Barisan pengeluaran kentang goreng Perancis, Barisan Pengeluaran Cip Pisang, Penauts menggoreng. penggoreng berterusan, Barisan Pengeluaran Kotor Kecil Kecil