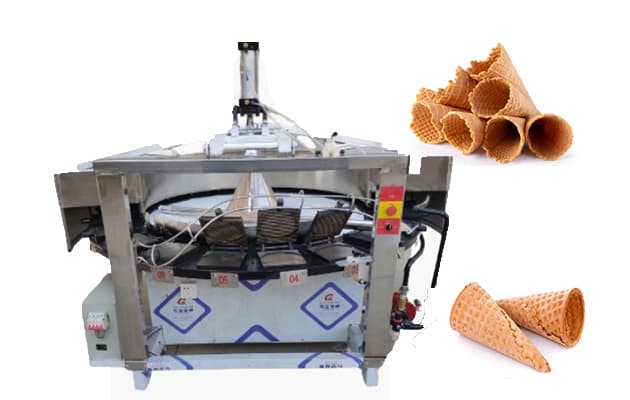

Pembuat Kon Wafel Mesin Kon Gula separuh automatik

Pembuat kon wafel is the ice cream cone machine designed for individual cone vendors, ice cream shops and ice cream factory, for its efficiency and multi-function.

The machine is customized to make delicious and crispy cookies and cream ice cream cone, small waffle cones, large waffle cones, different sugar cone size, mini ice cones, gulung wafel, ice cream bowl, Coklat ais krim coklat, Berjalan, cubanitos, Pizzelle, dan lain-lain.

We are waffle cone machine manufacturer and you will enjoy factory direct supply with thoughtful service.

Kapasiti: 300 keping sejam ke 1200 keping sejam

Waffle Cone Maker Application

Waffle Cone Maker is normally customized to make natural top edge waffle cones, flat top edge sugar cones, mangkuk wafel, flower shape cups etc. And the baking molds could also be customized for making waffle biscuit , gulungan telur, Italy Pizzelle, Kuih Kapit, cubanitos, barquillos etc.

Semi-automatic Waffle Cone Machine is the mainly used in bakeshops, kafe, and other snack food industry. Selain itu, mesin kon wafer automatik, semi-automatic wafer ice cream cone machine are also popular mesin kon aiskrim for baking various ice cream cones.

Waffle Cone Maker Introduction

Cone waffle machine includes grouting machine, mesin penaik, mesin membentuk.

Model: Mesin Waffle Separa Automatik, Automatic waffle cone machine

Kapasiti:300-8000PCS/H.

Harga: Harga terbaik, bekalan langsung dari kilang dengan kualiti tertinggi

Sumber pemanasan:Pemanasan /gas elektrik ( LNG atau LPG )

More on Semi-automatic ice cream cone making machine

Kapasiti: 300 pieces per hou, 600 pieces per hour, 800 pieces per hour, 1200pieces per hour.

(Kindly note that the above capacity range is for reference, dan juga pada model mesin yang sama, the final capacity could be slightly different due to the skill level of the worker’s operation, the size of the cone, dan lain-lain)

Bahan mesin: Untuk pembuat kerucut wafel komersial, Bingkai sokongan dan perisai penutup mesin diperbuat daripada keluli tahan karat 201 dengan standard. Ia adalah untuk keselamatan makanan dan tujuan yang mudah bersih.

To quickly heat up and improve thermal efficiency, the aluminium alloy material is good to use for baking plates/baking molds on electric waffle cone maker. manakala, the cast iron is not easy to deformed, so it is often used for baking plates / molds on gas heating waffle cone machine. Customized materials is acceptable upon customer’s special requirement.

Sumber pemanasan: Pemanasan elektrik / pemanasan gas ( gas asli atau gas petroleum cecair )

Semi-automatic ice cream waffle cone maker consist of the following

Waffle Cone Maker Specification

Model | DT-6 | DT-9 | DT-12 | DT-15 | DT-18 |

Kapasiti | 300 kepada 400 PCS/H. | 400 kepada 600 PCS/H. | 600 kepada 800 PCS/H. | 800-1000 PCS/H. | 1000-1200PCS/H. |

Kuasa pemanasan | 10kW | 15kW | 19.5kW | 23kW | 28kW |

Dimensi | 150*150*125cm | 160*160*125cm | 170*170*125cm | 180*180*125cm | 190*190*125cm |

Waffle Cone Maker Features

Kecekapan Tinggi:

Proses pembuangan adunan, biscuit baking, waffle cone rolling and waffle cone discharge is completed on one set of ice cream waffle cone maker. It is more efficient to use than homemade ice cream cone without machine. Pengguna dapat menikmati pulangan pelaburan yang lebih baik untuk kecekapan pengeluaran, mengurangkan kos buruh, dan meminimumkan sisa makanan.

Kawalan yang tepat:

There is separate heating control for each set of baking plates / Molds. Oleh itu, it is easier and convenient for customer to set and adjust baking temperature to achieve their best waffle cone quality and production capacity requirement.

Especially when user develop new recipe for trial test running, turn on the heating for several sets of baking plate and turn off the other, will help to save raw materials and avoid too much waste.

Kemungkinan pelbagai fungsi

It is common for user to make different products from one set of ice cream cone making machine to diversity their supply and also save investment cost. As a professional ice cream cone machine manufacturer, Kami memungkinkan pengguna kami membuat semua dalam satu mesin, such as waffle cone, Cone Gula, gulungan telur, cawan mangkuk, Pizzelle, waffle cookies etc.

Nota mesra, Penting bagi pengguna kami untuk bercakap dengan pasukan kami, Berkongsi reka bentuk produk akhir, saiz dan bentuk untuk mendapatkan penyelesaian akhir.

Sumber pemanasan mengikut keperluan pelanggan

Kekuatan pemanasan adalah salah satu faktor utama untuk kos pengeluaran. Oleh itu, Kami merancang dua jenis kaedah pemanasan yang tersedia untuk dipilih oleh pelanggan berdasarkan kos kuasa tempatan mereka.

Namun begitu, di sesetengah kawasan, Ramai pengguna baru merancang untuk menubuhkan perniagaan di rumah tanpa bekalan kuasa perindustrian. Sama sekali tidak akan menjadi masalah bagi mereka, since they have the gas heating ice cream cone maker which can be customized into home waffle cone maker.

Mesra Pengguna

The cone ice cream maker is very friendly to user without technical background or machine operation experience. It requires one operator to pick up ready baked waffle biscuit and put it on waffle cone shaper which we also called waffle cone rolling machine. Quite simple and safe to operate.

How to use a waffle cone maker ?

The cone maker is simple to use. Namun begitu, Setiap pengendali hendaklah membaca dan mengikuti buku operasi mesin yang kami sediakan untuk setiap pesanan. Berikut adalah langkah ringkas untuk diikuti:

- Letakkan mesin kerucut wafel ais krim di tanah rata. Laraskan bolt sauh untuk mengangkat kastor dari tanah.

- Sambungkan sumber udara dari pemampat udara untuk membentuk mesin atau dipanggil mesin rolling dan tangki adunan grouting.

- Plag mesin pembentukan kerucut, Tangki adunan adunan adunan ke mesin penaik biskut.

- Sambungkan mesin penaik ke kord kuasa kilang;Letakkan muncung adunan dari mesin grouting di tengah -tengah penaik piring.

- Hidupkan mesin penaik. (Masa baking dan suhu penaik adalah pratetap sebelum penghantaran, Tetapi ia boleh laras di tapak pengguna berdasarkan keperluan produk mereka.

- Selepas pengeluaran, pasangkan setiap mesin, dan memotong elektrik. Mesin penaik bersih, Membentuk mesin dan menanam tangki adunan mengikut buku pengguna.

DT Waffle Cone Machine Manufacturer

Tahan lasak dan Stabil

Mesin ini direka untuk berfungsi 8 jam setiap peralihan. Tetapi pelanggan dapat melanjutkan tempoh pengeluaran berdasarkan pesanan pasaran mereka. Dan ia menghasilkan kerucut ais krim dengan warna seragam dan saiz konsisten. The Cone QueLity baik dan membantu pelanggan kami memperoleh lebih banyak reputasi pasaran dan kesan jenama.

Kualiti dan Perkhidmatan yang terjamin

Mesin Waffle Cone Kualiti Meningkatkan Kapasiti Pengeluaran dan Kos Penyelenggaraan Bayar Pelanggan Kurang.

Selain itu, Kami menawarkan 12 jaminan kualiti bulan, panduan dan perkhidmatan pemasangan dan sokongan teknikal sepanjang hayat, dan bekalan alat ganti seumur hidup.

Lebih Bernilai kepada Pelanggan

Mesin Makanan DT menawarkan penyelesaian lengkap dari pesanan mesin anda, penghantaran , pemasangan, Resipi Waffle Cone kepada anda untuk membantu permulaan perniagaan makanan anda dan berjaya.

Selain itu, Kami menjalankan perniagaan untuk pelanggan kami,Untuk memenuhi quirement tersuai mereka pada bentuk produk akhir, Reka bentuk saiz dan patten atau logo. Kami juga menerima pengeluaran OEM dan ODM untuk pengedar mesin kami.

Cone Ice Cream Machine Price List

Waffle cone machine price is fixed within a period if customer make the ice cream cone , standard size without special design. Please contact our team for standard cone machine price list now.

manakala, for customer who prefer customized waffle cone design, logo atau corak, atau voltan yang disesuaikan pada mesin, Sila berbincang dengan pasukan kami mengenai keperluan terperinci anda dan kami akan menawarkan penyelesaian kepada reka bentuk anda dan membentangkan kos tersuai pada kos mesin standard.

What are waffle cones made of ?

The waffle cones is crispy and sweet. Bahan -bahannya adalah tepung gandum, gula, Minyak yang boleh dimakan, garam, dan air dll. Kami akan memberi anda nisbah resipi asas selepas pesanan dan anda boleh menambah bahan rahsia anda untuk mempunyai rasa dan rasa istimewa.

Mesin Berkaitan

Barisan pengeluaran ais krim automatik, Pembuat Wafer Cone, pengadun adunan, pemampat udara 4kW