Frozen French Fries Machine Automatic French Fries Processing Plant

French fries production line is an automatic and advanced production solution on processing potato into french fries.

Automatic french fries processing plant contains potato washing and peeling machine, french fries cutter machine, blanching machine, dewatering machine, french fries deep fryer machine, deoiling machine, cooling machine, quick freezer, automatic packing machine and its auxiliary equipments.

Applied to: Potato chips, sweet potato chips, long plantain chips, french fries, fresh french fries, frozen french fries, plantain chips etc.

Kapasiti: 50-100kg/j, 200-250kg/j, 350-400kg/j, 500kg/j, 1000kg/j, 1500kg/j, 2000kg/h and customized capacity.

Frozen French Fries Production Line Application

Frozen french fries making machine is advanced solution for frozen french fries manufacturers. No watter it is automatic potato french fries machine production line for larger french fries factories, or small scale frozen french fries production line for medium size factory or new french fries factory. Our potato processing plants enable investors with good returns by greatly reducing labor, improving product quality, providing productivity and market share.

Frozen chips making machine is also popular among snack food manufacturers who want the line to make various chips, such as potato chips, plantain chips, sweet potato chips etc. And Because of the seasonality of raw materials, they need a production line for off-season production to produce other products.

Frozen Potato Production Line Introduction

Frozen French Fries Production Line Description

Commercial french fries machine is a complete production line covering raw material washing and peeling machine, blanching machine, potato cutter, french fries fryer, quick freezer, automatic weighing and bagging machine.

And we customize potato processing plant to meet different business sizes. Oleh itu, we have semi automatic french fries production line for capacity 50kg per hour but also small scale french fries production line with output 100kg per hour, and fully automatic frozen french fries production line upto 2000kg per hour. Selain itu, we customize the french fries making machine with the capacity needed by customer.

French Fries Production Line For Sale Specification

Kaedah Pemanasan: Pemanasan elektrik / Pemanasan Gas

Bahan Mesin: Gred makanan 304 Bahan streel tahan karat, Kualiti terbaik dibuat

Oil Heating Temperature: 0℃ to 300℃ (Fahrenheit 32°F to 572.0 °F )

Kapasiti: 50KG/H to 2000KG/H (Kapasiti yang lebih tinggi dapat disesuaikan)

Factory space requirement: We can customized the production line based on the factory size and floor plan.

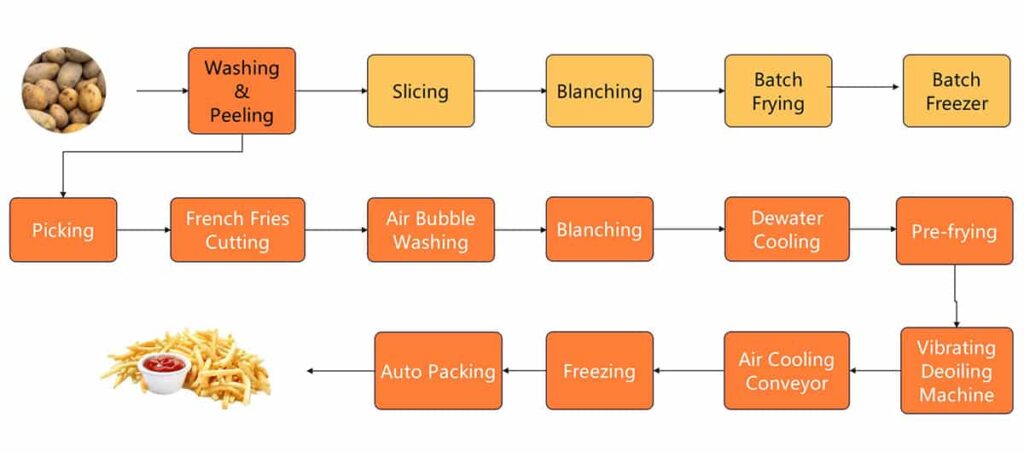

Fully Automatic French Fries Machine Flow Chart

It includes small scale french fries production line semi-automatic and fully automatic french fries production line processing flow.

French Fries Machine Features

Potato Peeling Machine

This is washing and peeling machine continuous membasuh, peeling and discharging.

Because the uneven and corrugated brushes is composed of stiff bristle brush and emery brush which enable to peel the potatoes completely.

Selain itu, the sprial type peeling machine push the potato foward and discharge from the other end to picking conveyor belts before slicing process.

Moreover, it is suitable for washing and peeling potato, sweet potato, cassava, ginger, onion, carrots etc.

French Fry Potato Cutter Machine Electric

potato french fries cutting machine is commercal french fries cutter with high output. And french sticks size 7*7mm, 8*8mm, 10*10mm, and custom-made can be changed by adjusting the blade.

French fries cutter machine is also suitable for other root vegetables, like carrots, cassava, dan lain-lain.

The end product is smooth, uniform and free of breaks.

Blanching Potatoes Before Frying

This is blanching machine to protect the french sticks color and remain goods taste.

Potato chips branching time is about 5 to15 minutes at hot water temperature 70℃ (158.0 °F). And the stainless steel mesh belt is with frequency conversion speed regulation, so the blanching time and speed is adjustable.

There are continuous branching machine with gas heating and continuous branching machine with electric heating for customer to choose.

Potato dewatering machine

Air cooling machine removes the water and cool down the temperature of branched potato sticks before frying. It shortens the frying time and ensure the quality taste of french fries.

And to have better effect, a vibrating deoiling macine is necessory to be used before air drying and dewatering conveyor belt.

french fries deep fryer machine

For small scale potato chips plant, the basket type deep fryer or round pot frying machine is ideal choice for capacity below 200kg an hour.

Namun begitu, for fully automatic french fries production plant, the continuous frying machine is best option to keep the frying time continuous working with larger capacity and less labors. Best french fries machine is stainless steel materials and its frying time is adjustable and oil temperature adjustable.

Selain itu, we can also customize the fryer to automate the process of oil refill, oil recycle, oil filtering and self cleaning system. This will greatly improve the production efficiency, prolong oil usage and bettter quality french fries.

Deoiling Machine

Vibrating Deoiling machine is neccessory to remove oil on surface of french fries after frying.

Because, the fried french sticks from frying line normally carry some oils which cause the product oily and may polute the production floor. Oleh itu, the vibrating machine with oil receiving plates is good to deoiling the oil from chips surface and keep the production site clean.

Lebih banyak lagi, during vibrating process, the chips are moving foward and spread even to next process.

Mesin penyejuk

Cooling conveyor is installed with ventilators blowing wind to french fries. Therefore the surface temperature drop sharly by natural strong wind. This is important process before quick freezing process.

And oil receiving plate under the cooling conveyor is optional to receive oil dropped from french fries.

Fries Freezer Tunnel Freezers IQF Freezers

French fries quick freezer is applicable to freeze large quantities of french fries in short periods of time without causing any clumps from developing or having the product stick together.

Center temperature of material to feed:<20 C

Discharge temperature: -18℃

Freezing time: 15 min to 45minutes.

Packing Automatic Machine with Weighing, Filling and Bag Making

To pack frozen french fries into plastic bag automatically, the automatic pouch filling and sealing machine is ideal choice. It includes elevator, penimbang pelbagai kepala, bentuk rata, peranti membuat beg dengan fungsi cetakan tarikh, dan penghantar produk akhir.

Lebih banyak lagi, the chips packing machine has advantage of high efficiency, accurate weighing, and working continuous with the french fries processing line.

French Fries Processing Line Parameter

Frozen French Fries Machine List as below for reference only. And we are able to customize the fries processing line based on customer factory layout, voltan, end product varieties, packing type etc.

| Tidak. | Nama mesin | Quantity | Unit | Kadar voltan |

| 1 | Elevator | 1 | Set | 380V 50HZ 3ph Can be customized |

| 2 | Potato washing and peeling machine | 1 | Set | 380V 50HZ 3ph Can be customized |

| 3 | Select conveyor belt | 1 | Set | 380V 50HZ 3ph Can be customized |

| 4 | Potato cutter | 1 | Set | 380V 50HZ 3ph Can be customized |

| 5 | Bucket spray lift | 1 | Set | 380V 50HZ 3ph Can be customized |

| 6 | Unqualified French fry picking machine | 1 | Set | 380V 50HZ 3ph Can be customized |

| 7 | Rinse machine | 1 | Set | 380V 50HZ 3ph Can be customized |

| 8 | Blanching machine | 1 | Set | 380V 50HZ 3ph Can be customized |

| 9 | Vibration dehydrator | 1 | Set | 380V 50HZ 3ph Can be customized |

| 10 | Air-cooled dryer | 1 | Set | 380V 50HZ 3ph Can be customized |

| 11 | Elevator | 1 | Set | 380V 50HZ 3ph Can be customized |

| 12 | Continuous frying machine | 1 | Set | 380V 50HZ 3ph Can be customized |

| 13 | Vibrating deoilingg machine | 1 | Set | 380V 50HZ 3ph Can be customized |

| 14 | Air-cooled dryer | 1 | Set | 380V 50HZ 3ph Can be customized |

| 15 | French Fries Spreading Machine | Set | 380V 50HZ 3ph Can be customized | |

| 16 | Freezer | 1 | Set | 380V 50HZ 3ph Can be customized |

| 17 | Mesin Pembungkusan | 1 | Set | 380V 50HZ 3ph Can be customized |

French Fries Making Machine Factory

Kelebihan

Kilang jentera makanan sehenti

30 tahun r&D Sejarah

Prestasi jentera yang stabil

Pada masa penghantaran

Jaminan

12 Jaminan Kualiti Bulan

Sokongan teknikal seumur hidup dan perkhidmatan alat ganti

Perkhidmatan

Sokongan selepas jualan dalam operasi, penyelenggaraan.

Latihan Percuma dalam talian atau luar talian di kilang

Pemasangan di tapak di kilang Pelanggan

Keseluruhan nasihat perniagaan untuk perancang perniagaan baharu.

Perkhidmatan penghantaran ke negara pembeli

French Fries Machine Price

We have professional technical engineer team and product develope team to updgrating our production line for higher efficency, less production and better user satisfactory. Selain itu, we understand and quick respond to customer needs with the right solution to their business.

You are most welcomed to contact our team now for a french fries manufacturing plant cost..

What is the best potato used for frozen french fries line?

Shepody is a white-skinned potato cultivar that originated in New Brunswick, Canada and is used for boiling, membakar, and French frying. Its dry matter 19-21%, low reducing sugar content≤ 0.4% , especially suitable for frying processing.

Lebih banyak lagi, french fries in fast food restaurants and potato chips in supermarkets are mass-produced in factories. The well-shaped, light-eyed Shepody is easy to peel during production, and the resulting potato chips and french fries rarely showing holes and scars.

Oleh itu, Shepody is ideal potato types for frozen french fries production.

Mesin Berkaitan

Potato chips machines, banana chips production line, penauts frying line. continuous fryer, small scale potato chips production line