What Is a Cocoa Powder Production Line?

A cocoa powder production line is a comprehensive system of equipment and machinery designed to process raw cocoa beans into fine cocoa powder, a key ingredient in chocolate, membakar, and beverage industries. This line handles each stage of transformation, including roasting, winnowing, mengisar, pressing, and powdering.

Cocoa powder processing lines vary in scale and level of automation. Industrial lines are fully automated and capable of processing tons of cocoa beans daily, while small-scale setups are suitable for craft chocolate makers or startups. Regardless of scale, the aim remains the same: consistent, high-quality cocoa powder with optimal flavor and aroma.

Core Components of Our Cocoa Powder Processing Equipment

1. Cocoa Bean Roasting Machine

Roasting is the first crucial step in developing flavor. Our roasters ensure uniform heating with temperature control ranging from 120°C to 160°C. Features include drum or hot air roasting options, energy efficiency, and programmable settings.

2. Cocoa Winnower

Post-roasting, the beans are cracked and shells removed using the winnower. Our high-efficiency winnowers separate nibs and husks accurately with minimal loss, preparing the beans for grinding.

3. Cocoa Grinding Mill

The grinding mill transforms nibs into cocoa liquor or paste. Our machines use stainless steel grinding rollers or discs to achieve fine particle sizes (up to 75 microns), essential for smooth texture.

4. Mesin tekan mentega koko

This hydraulic press extracts cocoa butter from the paste, leaving behind cocoa cake. Pressing efficiency reaches up to 85%, and the automated pressure control ensures safe and precise operations.

5. Cocoa Cake Crushing and Pulverizer

Cocoa cakes are crushed and pulverized into powder using our high-speed hammer mills. Adjustable mesh sizes allow for different grades of fineness according to your product requirements.

6. Powder Separator and Sieving System

To ensure purity and consistency, the powder goes through vibratory sieves to eliminate oversized particles and foreign bodies, resulting in a uniform final product.

7. Automatic Packaging Machine

Our integrated packing units weigh, fill, and seal cocoa powder into bags ranging from 100g to 25kg. Options for nitrogen flushing, date stamping, and vacuum sealing are available.

Turnkey Cocoa Powder Production Line Solution

We offer end-to-end cocoa powder production line solutions tailored to your needs. Our turnkey systems include:

- Plant layout and flowchart design

- Equipment customization (kapasiti, automation, bahan)

- Installation and commissioning services

- Operator training and technical documentation

- Ongoing technical support and spare parts

Cocoa Powder Production Line – Technical Specification

| 📌 Process Step | ⚙️ Equipment Name | 🔢 Model | 📦 Kapasiti | ⚡ kuasa | 🧱 Bahan | 📐 Dimensions (mm) | 📝 Remarks |

|---|---|---|---|---|---|---|---|

| 1️⃣ Roasting | Koko kacang roaster | DT-R500 | 500 kg/j | 24 kW | SUS304 Stainless Steel | 2200 × 1450 × 1800 | Hot air or rotary drum optional |

| 2️⃣ Winnowing | Cocoa Winnower | DT-W500 | 500 kg/j | 7.5 kW | SUS304 | 1700 × 950 × 1650 | Automatic nib/shell separator |

| 3️⃣ Grinding | Cocoa Nib Grinder | DT-GR500 | 500 kg/j | 11 kW | SUS304 | 1300 × 850 × 1450 | Fineness ≤ 75 μm |

| 4️⃣ Liquor Storage | Heated Holding Tank | DT-TK500 | 500 L. | 3.0 kW | SUS316 + Insulated | 1000 × 1000 × 1600 | With stirrer + temp control |

| 5️⃣ Pressing | Hydraulic Cocoa Butter Press | DT-HP300 | 300 kg/j | 18.5 kW | SUS304 + Carbon Steel | 1600 × 1100 × 1900 | ≥85% pressing efficiency |

| 6️⃣ Cake Crushing | Cocoa Cake Crusher | DT-CR500 | 500 kg/j | 5.5 kW | SUS304 | 1250 × 950 × 1100 | Coarse-to-fine adjustable blades |

| 7️⃣ Powder Milling | Fine Powder Pulverizer | DT-PUL500 | 500 kg/j | 11 kW | SUS304 | 1350 × 1050 × 1700 | 20–120 mesh options |

| 8️⃣ Sieving | Vibratory Powder Sieve | DT-VS500 | 500 kg/j | 2.2 kW | SUS304 | 1050 × 900 × 1300 | Multi-deck rotary sieve |

| 9️⃣ Dust Control | Dust Collector + Hopper | DT-CL500 | 500 kg/j | 1.5 kW | SUS304 + Filters | 1200 × 800 × 1600 | GMP-compliant dust control |

| 🔟 Packaging | Automatic Packing Machine | DT-PK10K | 10–25 kg/bag | 2.0 kW | SUS304 | 1500 × 1200 × 1500 | Weighing + sealing + optional nitrogen |

Optional Equipment

| ✅ Optional Feature | 💡 Function |

|---|---|

| PLC Touchscreen Control | Full line automation, real-time control |

| CIP Cleaning System | Clean-in-Place system for hygiene compliance |

| IoT Monitoring Module | Remote diagnostics, cloud-based analytics |

| Nitrogen Flush System | For extended cocoa powder shelf life |

| Cooling Water Chiller | Prevents heat buildup in grinder/press |

| CE/ISO/FDA Certificates | Compliance for food production export requirements |

Voltage Configuration

| 🌍 Region | ⚡ Voltan | 🔄 Frequency |

|---|---|---|

| Eropah | 380V / 415V | 50Hz |

| North America | 220V / 440V | 60Hz |

| Asia / Timur Tengah | 380V | 50Hz |

| Africa | 380V | 50Hz |

Whether you’re upgrading an existing facility or building a new plant, we deliver a seamless project from start to finish.

Why Choose Us as Your Cocoa Powder Line Manufacturer?

With over 15 tahun pengalaman dalam peralatan pemprosesan makanan, we specialize in designing and manufacturing advanced cocoa powder production lines. Here’s why global clients choose us:

- Certified Quality: CE and ISO 9001 certifications

- Global Projects: Successful installations in over 30 negara

- R&D Focus: In-house engineers constantly improve designs

- Penyesuaian: Tailored equipment solutions for any scale

- Service Commitment: 24/7 online support and spare parts supply

Our factory supports OEM & ODM orders and welcomes customer visits for in-person evaluations and trials.

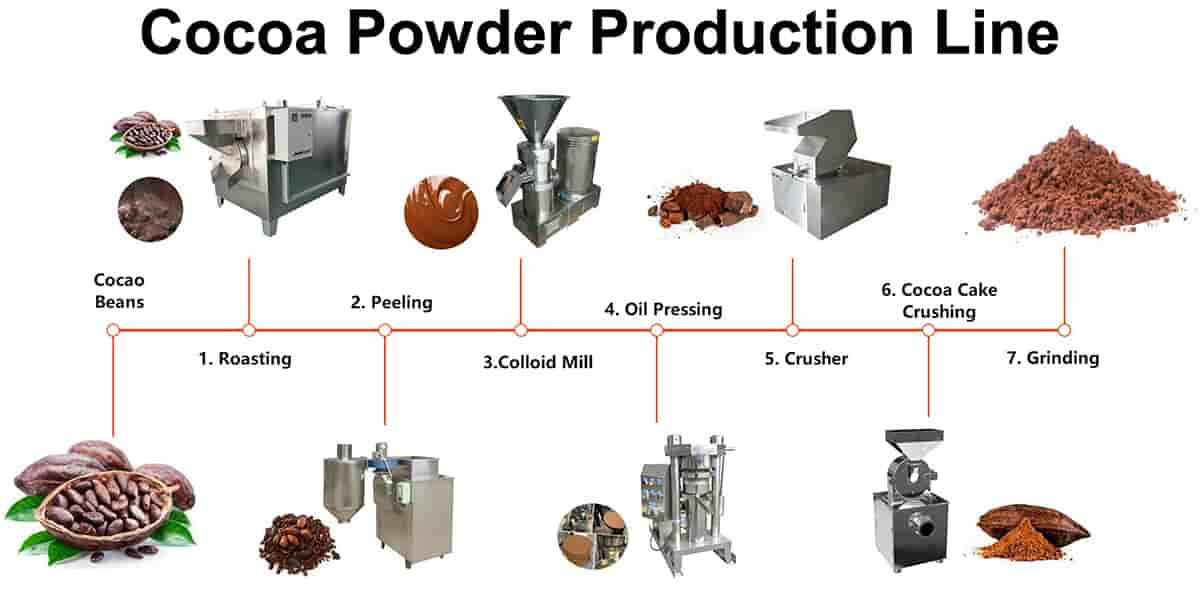

Cocoa Powder Production Process Overview

Here is a step-by-step outline of the cocoa powder manufacturing process:

- Cleaning: Remove dust, stones, and foreign matter from raw cocoa beans

- Roasting: Enhance aroma and flavor, reduce moisture

- Winnowing: Remove shells to collect cocoa nibs

- Grinding: Convert nibs into cocoa liquor

- Pressing: Separate cocoa butter and cocoa cake

- Crushing: Break cake into manageable pieces

- Pulverizing: Mill into fine cocoa powder

- Sieving: Filter and grade final powder

- Packaging: Automatically bag for sale or distribution

Our line is designed for energy efficiency and minimal manual handling, reducing labor costs and improving food safety.

Applications and End-User Industries

Cocoa powder produced by our line is suitable for a wide range of industries:

- Confectionery: Chocolate bars, truffles, coatings

- Bakery: Cakes, brownies, cookies

- Beverages: Instant hot chocolate, flavored milk drinks

- Nutritional Products: Protein powders, supplements

- Food Ingredient Suppliers: Bulk cocoa powder for resale

With food-grade stainless steel construction, our equipment ensures compliance with hygiene and safety standards across all industries.

Custom Cocoa Powder Line Design & Capacity Options

Our cocoa powder lines are available in standard and custom configurations:

- Small Scale: 100 kg/hour – Ideal for labs, R&D, or startups

- Medium Scale: 500-1000 kg/hour – For local market production

- Large Scale: 2 tons/hour and above – Full industrial operation

Optional features include:

- PLC control systems with touchscreen interfaces

- CIP (clean-in-place) system

- Remote monitoring and diagnostics

- Modular line design for easy expansion

Each line can be customized based on your floor space, production goals, and regional power standards.

Installation, Commissioning & Sokongan selepas jualan

To ensure a smooth launch, we provide:

- Overseas Installation Services: Technicians travel to your site

- Training Programs: Hands-on training for operators

- Technical Documents: English manuals, wiring diagrams, SOPs

- Spare Parts Support: Fast delivery from warehouse

- Warranty Service: 12-month warranty with lifetime technical support

We stay connected through WhatsApp, Zoom, or on-site visits to troubleshoot and optimize your line.

Get Your Cocoa Powder Line Quote Today

Looking to set up a cocoa powder factory? Contact us with your project details:

- Expected production capacity

- Available workshop space

- Desired level of automation

- Budget and timeline

Our engineers will send you a detailed proposal with layout, equipment specs, and quotation within 48 hours.

Contact us today to get a free consultation and start building your own cocoa processing plant!

FAQs About Cocoa Powder Production Equipment

Q1: What is the cost of a cocoa powder production line?

A: Prices vary depending on capacity and configuration. Small lines start from $30,000, while large-scale setups can exceed $500,000.

Q2: How much space is needed?

A: A small line can fit in a 100 sqm workshop, while industrial lines may need 500 sqm or more.

Q3: Can the machine process organic cocoa beans?

A: Ya, our machines are suitable for organic production with food-grade materials.

Q4: Do you offer international shipping and installation?

A: Ya, we export worldwide and provide on-site services.

Q5: How long does delivery take?

A: Standard equipment ships in 25-35 days. Customized orders may take 45-60 days.

Looking for a reliable cocoa powder production line manufacturer? We are your trusted partner for quality, service, and innovation in cocoa processing technology.