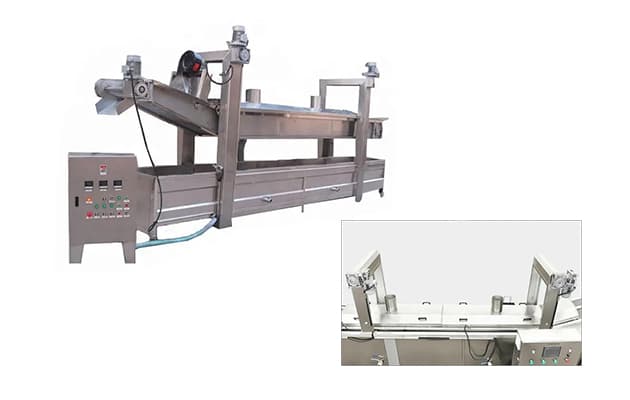

Тахианы махны шарсан маханд зориулсан тасралтгүй шарагч

Тасралтгүй Фрайер is an automatic and continuous frying system used in automatic chicken nuggets production line, pellet frying line, Францын шарсан үйлдвэрлэлийн шугам, Автомат төмсний чипс үйлдвэрлэлийн шугам, banana chips line etc.

Хүчин чадал: 100kg/h to 1500kg/h, and customized according to requirement.

Халуушны эх үүсвэр: Цахилгаан, Gas/LPG gas, Diesel to choose

Материал: Food grade stainless steel 304

Continuous Fryer Application

Continuous fryer is a fully automatic frying machine to realize continuous frying process, oil temperature control, frying time set, fried food and snacks automatically discharging.Since the frying machine greatly saves labor costs and improve the whole production line efficiency. And because of its many advantages, automatic frying machine is a most preferred choice for food factory production line.

Auto fryers is used for continuous frying chips, nuts, Францын шарсан мах, namkeen, дуу уг Газмаг, cashew самар, загасны арьс, гал наран арьсан арьс, тартаны чипс, Францын шарсан мах, төмсний чипс, тахианы цул, хавар шугамна, pani puri etc.

Түүнээс гадна, the continuous deep fry equipment plays an important part in automatic food production line, сурталчилга automati frozen french fries production line, chicken nuggets processing line, burger frying line, гадил жимсний чипс үйлдвэрлэх шугам, peant frying line etc.

Continuous Frying Machine Introduction

Automatic Fryer Machine Description

Continuous deep fry equipment is a continuous frying system, covering belts transmission to control frying time, belt evelavtion for cleaning, oil temperature control and adjustment.

And the fryer machine is built with double layer mesh belts to sandwich the floating materials into oil complete. And the belts are normally customized based on the frying materials.

Түүнээс гадна, external heating fryer with large capacity also design with residue and waste scrapping system, oil refill system, oil filtering and reserve system etc.

Илүү юу байна, frying machine is not only used alone in workshops or central kitchen, but also used to continuous working in automatic food production line.

Continuous Industrial Fryer Specification

Хоол арга цэг: Цахилгаан халаалт / Хийн халаалт / Diesel Heating

Машины материал: Хүнсний зэрэг 304 зэвэрдэггүй ган материал, хамгийн сайн чанарын хийсэн

Температур хянах: Have Automatic oil temperature control system

Газрын тос халаалтын температур: 0℃ 300 ℃ (Фаренгейт 32 ° F 572.0 ° F)

Хүчин чадал: 100KG/H to 1500KG/H and customized capacity (according to fryer machine models and raw materials)

Automatic Frying Machine Type and Advantage

Mini Fryer Continuous Frying Machine

Mini Donut Frying Machine is used to fry donuts, kurkures, muruku, chinchin biscuit, хавар шугамна, samosa etc.

Chicken Nuggets Mini Frying Machine can be use for frying chicken legs, тахианы далавч, sweet potato chips with few minutes of frying time.

Mini chips fryer is used for frying french fries, төмсний чипс, баняа, peanuts etc.

Давуу тал

One outstandarding advantage of Mini Fryers is that they can be customized for making shrimp cracker, macaroni cracker, pork rinds cracker with frying time ranged in few seconds.

Түүнээс гадна, it is economical and continuous choice for new start business or small and medium scale food production.

Continuous Frying Machine Electric Heating Fryer

Automatic electric oil fryer is suitable for chicken nuggets, burger frying, нөмрөг, cheese dogs, дуу уг Газмаг, cashew nets, хавар шугамна, samosa etc.

Давуу тал

It is easier to clean after production.

And the heaters heat oil dierctly, energy saving and oil heated up quickly.

More accurate oil temperature control to make sure better products with even color and high quality.

Continuous Frying Machine Gas Heating Fryer

Gas chips fryer is suitable for frying banana chips, тартаны чипс, Францын шарсан мах, хавар шугамна, potato chips etc.

Давуу тал

Gas heating continuous frying machine is energy saving and preferred choice in some countries and regions that gas is far more cheaper than electricity. Тиймээс, the production cost is reduced a lot.

Continuous Chips Fryer Features and Advantage

Double Layer Conveyor Belts Adjustable Frying Time

Upper and lower conveyor belts push the fried food from inlet to outlet of the frying machine. Тиймээс, the frying time is adjustable by setting up the conveying speed.

The upper belt with scrapper could press the floating materials into oil completely and push it moving forward. Үр дүнд нь, the fried food color is even and quality is good.

Conveyor belts on automatic fryer machine are customized and able to replace according to production need. Жишээ нь, we have fryers built with mesh belts, chain belts, stainless steel flat flex wire mesh onveyors belt etc. according to raw material features.

Automatic Lifting System Easy Cleaning

Continuous deep fryers is built with automatic lifting system. To lift the top cover and conveyor belts up after production. It make the cleaning and maintance work more easier and convenient.

Oil Filtering System (Сайн дурын) Improve Oil Quality

In some situation that the raw materials is chicken nuggets, fish nuggets, breaded spring rolls etc, the breadcrums or waste could left in the oil during frying process. Then the oil filtering system is necessory to online filter the oil or start oil filter after production.And the fried products is of more better quality.

While in bigger production line for frying plantain chips, дуу уг Газмаг, төмсний чипс, Францын шарсан мах, гэх мэт, the oil filter system greatly improve oil quality.

Self Clean System (Сайн дурын) Improve Product Quality

To improve product quality, the self clean system is an option. It removes the waste sink to bottom out during production. This could prolong the oil usage life and make sure the fried product quality as well.

Automatic Chips Fryer Machine Parameter

Electric Heating Continuous Frying Machine

| Загвар | Хүчин чадал (Түүхий хутга) | Хүч | Жин | Fryer Size | Oil Temperature |

| DT-CF-3500E | 500кг/цаг | 80kw | 1000кг | 3500*1200*2400мм | 0-300 ℃(Fahrenheit 32°F to 572.0 ° F) |

| DT-CF4000E | 600кг/цаг | 100kw | 1200кг | 4000*1200*2400мм | 0-300 ℃(Fahrenheit 32°F to 572.0 ° F) |

| DT-CF-5000E | 800кг/цаг | 120kw | 1500кг | 5000*1200*2400мм | 0-300 ℃(Fahrenheit 32°F to 572.0 ° F) |

| DT-CF-6000E | 1000кг/цаг | 180kw | 1800кг | 6000*1200*2400мм | 0-300 ℃(Fahrenheit 32°F to 572.0 ° F) |

| DT-CF-8000E | 1500кг/цаг | 200kw | 2000кг | 8000*1200*2600мм | 0-300 ℃(Fahrenheit 32°F to 572.0 ° F) |

| Remark: Final capacity for each model is varied according to fried material and its required frying time. | |||||

Gas Heating Continuous Frying Machine

| Загвар | Хүчин чадал (Түүхий хутга) | Эрчим хүч ердийн клуб | Машины жин | Fry Size | Oil Temperature |

| DT-CF-3500 | 500кг/цаг | 300,000 kcal | 1200кг | 3500*1200*2400мм | 0-300 ℃(Fahrenheit 32°F to 572.0 ° F) |

| DT-CF-4000 | 600кг/цаг | 500,000 kcal | 1500кг | 4000*1200*2400мм | 0-300 ℃(Fahrenheit 32°F to 572.0 ° F) |

| DT-CF-5000 | 800кг/цаг | 500,000 kcal | 1700кг | 5000*1200*2400мм | 0-300 ℃(Fahrenheit 32°F to 572.0 ° F) |

| The fina capacity for each model is varied according to fried material and its required frying time. | |||||

Chips Fryer for sale Continuous Potato Frying Machine

Chips fryer could use alone, but also can use with chip slicer, тос арилгах машин, cooling machine and seasoning machine to make a continuous potato chips production line, banana chips production line etc.

We can customize the production line solution and recommend suitable machines based on your business capacity and factory space. Welcome to contact our team now to get a detailed quotation.

How to use continuous chips fryer machine?

After industrial frying machine is installed and checked, cleaned, trial tested at factory. User can start production based on their plan.

Гэсэн хэдий ч, here is brief operation process for user to follow after installation.

- Water clean the oil tank, frying tank and conveyor belt, and wipe off the moisture.

- Fill oil directly from up side of fryer, or connect oil storage tank to fryer to pump oil inside fryer.

- Turn on the fryer and set up the oil temperature and start heating oil the oil.

- Switch on the conveyor to adjust suitable speed of conveyor to find the most suitable frying time for the products.

- For oil refill during production, could manually fill the oil / or fill the oil from oil storage tankto make sure oil level touch the upper belts.

- Үйлдвэрлэл хийсний дараа, wait for oil temperature cool down below 60℃ and pump out to oil storage tank, or go filtering the oil before going to oil storage tank.

Continuous Fryer Manufacturer

Баталгаа

12 Сарын чанарын баталгаа

Цэвэр зардлын үед сэлбэг хэрэгслийн үйлчилгээ

Үйлчилгээ

Борлуулалтын дараах дэмжлэг ажиллаж байна, засвар үйлчилгээ.

Үйлдвэр дээр онлайн эсвэл офлайн үнэгүй сургалт

Хэрэглэгчийн үйлдвэрт газар дээр нь суурилуулах

Шинэ бизнес төлөвлөгч нарт бизнесийн ерөнхий зөвлөгөө өгдөг.

Худалдан авагчийн улс руу хүргэх үйлчилгээ

Related Fish and Chips Fryer

Deep fryer basket frying machine, batch type potato chips production line, peanut frying line, chinchin production line