Төмсний чипний машин, шарсан төмсний машин, төмсний чипсийн автомат шугам

Төмсний чип машин Тариалангийн төмсний урсацын тоног төхөөрөмж нь шар айраг шарсан төмсний чипс рүү.

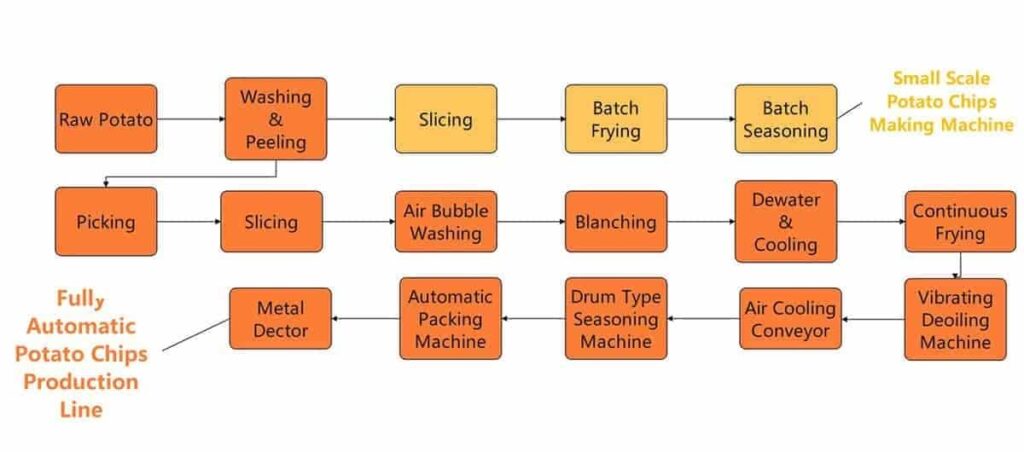

Автомат төмсний чипс шугам төмсний угаах, хальслах машиныг агуулдаг, чипс таслагч машин, төмс цайруулах машин, төмсний чипс dewating машин, төмсний чипс Фрайер, тос арилгах машин, хийн хөртж машин, Төмсний чипс амтлагч машин, төмсний чипс баглаа боож боох машин ба түүний туслах тоног төхөөрөмж, бүх мөрийг бүрэн автоматаар автоматаар автоматаар автоматаар ажиллуулах.

Хэрэглэсэн: Төмсний чи, Францын шарсан мах, plandain чипс гэх мэт.

Хүчин чадал: 50-100кг/цаг, 100-150кг/цаг, 200-250кг/цаг, 350-400кг/цаг, 450-500кг/цаг, ба түүнээс дээш хүчин чадалтай.

Төмсний чип машин програм

Төмсний чип машин төмсний чипс үйлдвэрт илүү том эсвэл дунд хэмжээтэй төмсний боловсруулах үйлдвэртэй үйлдвэрлэдэг. Үйлдвэрлэлийн өндөр үр ашиг, эрүүл ахуйн хоол хүнс,бүрэн автомат төмсний чипс шугам нь хөрөнгө үйлдвэрлэгчдийг бага үйлдвэрлэгчдэд бага үйлдвэрлэгчдэд олгодог, тиймээс хөрөнгө оруулалтыг илүү сайн буцааж авах.

Ба, бага хэмжээний төмсний чипс хийх машин Жижиг бизнес дээр эхлэх төлөвлөгөөтэй хүнсний боловсруулалтын компанид сайн байдаг.

Түүнээс гадна, Чипсэд зориулсан машин нь хурууны чипийг хийх шугамыг тохируулж болно, баняа , амтат төмсний чипс, гэх мэт.

Төмсний чипс машины тухай танилцуулга

Төмсний чипс үйлдвэрлэгчийн тодорхойлолт

Төмсний чипс хийх машин бол төмсний угаах зориулалттай төмсний боловсруулалт юм, хальслах, нисэнэ, шарсан, амтлагч, баглаа боодол. Чипс шугамууд өндөр байна хүчин чадал, Мэргэшсэн, эрүүл ахуйн хоолтой супер үр ашгийг.

Бизнесийн өөр өөр эрэлт хэрэгцээг хангахад, Бид хагас автомат төмсний чипс үйлдвэрлэлийн үйлдвэрийг 20-50 кг / H эсвэл 50-100KG / H-ийн хүчин чадалтайгаар боловсруулсан болно. Гэхдээ бид төмсний чипсийг 500 кг / H-ийн хүчин чадлаар бүрэн автомат машинаар боловсруулсан болно.

Цэвэр чипс үйлдвэрлэгчийн хэрэгслийн тодорхойлолт

Хоол арга цэг: Цахилгаан халаалт / Хийн халаалт

Машины материал: Хүнсний зэрэг 304 зэвэрдэггүй ган материал, хамгийн сайн чанарын хийсэн

Газрын тос халаалтын температур: 0℃ 300 ℃ (Фаренгейт 32 ° F 572.0 ° F)

Төмс, төмсний чипсийн харьцаа: 4 : 1 Ашигласан материал.

Хүчин чадал: 50Kg / h нь 500 кг / цаг хүртэл (өндөр хүчин чадалтай чипс үйлдвэрлэгчийг өөрчлөх боломжтой)

Үйлдвэрийн талбайн шаардлага: Бид үйлдвэрийн хэмжээ, шалны төлөвлөгөөнд үндэслэн үйлдвэрлэлийн шугамыг өөрчилж болно.

Төмөр далайн барилгын нь бүтээлийн шугамын шугам

Төмсний чип үйлдвэрлэлийн шугамын онцлог шинж чанарууд

Төмсний хальслах машин

Mall масштабын chips chip-ийн үйлдвэрлэлийн шугам, бatch төрлийн төмсний хальслах машинууд үр ашигтай угаах, илүү их давуу талтай, гарын авлагаас илүү их хальслах давуу талтай.

Мөн бүрэн автоматаар төмсний чипс үйлдвэрлэлийн шугам, Энэ нь тасралтгүй төмсний угаах, хальслах машин хийх шаардлагатай. Лифттэй ажиллах, Энэ нь тасралтгүй түүхий төмс тэжээлийг ухаарах болно, угаах, хальслах, буулгах үйл явц.

Түүнээс гадна, Sprial Type Sperate машин нь төмсний хэрэгслийг түлхэж, зүсэх үйл явцыг сонгохоос өмнө SONVEYOR BEACE-ийг дарж, нөгөө үзүүрээс нь Soleveyor бүсийг сонгоод нөгөө үзүүрийг нь зүсэх үйл явцыг сонгоно.

Тиймээс, төмсийн төмсний автомат машиныг дунд, том, том тэнхээг төмрийн үйлдвэрийн талбайд ашигладаг.

Чөлөөхэнүүхэн, Үүнийг угааж, хальслахад тохиромжтой, чихэрлэг төмс, кассава, гол, сонгино, лууван гэх мэт.

Чипс хэрчсэн машин

Төмсний таслагч машин нь төмсний зүсмэлүүдийг бүр зузаантай тайрч болно. Ба зүсмэлийн зузааныг хэрэгцээний дагуу тохируулж болно.

Түүнээс гадна, Төмөр чип таслагчийн машиныг үйлдвэрлэлийн хүчин чадлаар үндэслэн, хэрэгцээтэй өөр өөр загварууд байдаг.

Шарсан махыг авахаас өмнө төмс төмс

Том хүчин чадалтай төмсний чипс үйлдвэрлэлийн шугамын шугамд, Бланчинг машин чип өнгийг хамгаалахын тулд чухал үүрэг гүйцэтгэдэг бөгөөд барааны амт хэвээр үлдэнэ.

Төмсний чипс салбарлах цаг болжээ 5 халуун усны температур 70 ℃ (158.0 ° F)

Хийн халаалт, тасралтгүй мөчир, тасралтгүй мөчиртэй кабель нь үйлчлүүлэгчийг сонгохын тулд цахилгаан халаалттай.

Түүнээс гадна, Салбарын машин нь төмсний чипсийг салгахад тохиромжтой биш юм, Гэхдээ мөн гадил жимсний чипс, Франц шарсан мах болон бусад материал.

Төмсний гоймон машин

Агаарын хөргөлтийн машин нь усыг арилгаж, шарсан төмсний чипсийг шарсан төмсний чипсийг хөргөнө.

Илүү сайн нөлөө үзүүлэх хэрэгтэй, Агаарын хатаах, нугасны хатаах, нугасны хатах, шүүдэртэй конвейер бүсээс өмнө ашиглах нь зайлшгүй шаардлагатай байдаг.

Төмсний тууз

Жижиг хэмжээний төмсний чипс ургамал, Хагас автоматаар шарсан зураас шугам нь дугуй савны шарсан махыг тойрсон хамгийн тохиромжтой сонголт юм.

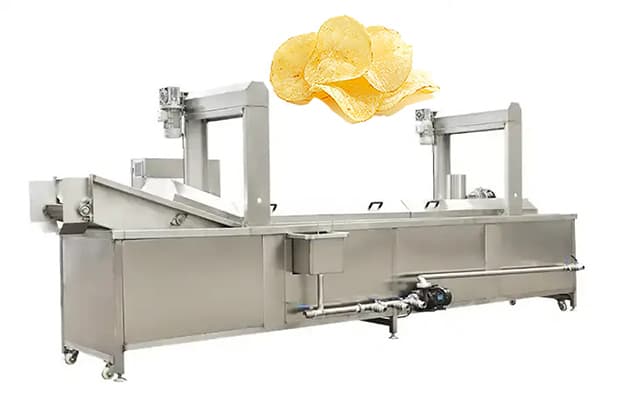

Гэсэн хэдий ч, Автомат чипс үйлдвэрлэлийн үйлдвэрт зориулж, тухайлах ялгац гишүүн тасралтгүй хайруулын машин Шарсан цаг хугацааг илүү том хүчин чадал, бага хөдөлмөр, бага хөдөлмөрөөр тасралтгүй ажиллахад шаардлагатай байдаг. Шарсан чипс нь бүр шарсан өнгө, сайхан амттай байх ёстой. Түүнээс гадна, газрын тосны дүүргэх систем, Газрын тосны дахин боловсруулалт, газрын тосны шүүлтүүрийн систем, машин өөрөө цэвэрлэх систем нь үйлдвэрлэлийн үр ашгийг сайжруулах болно, Уржгар газрын тосны хэрэглээ ба Беттерийн чанарын чипс.

Хойшлуулах машин

ДЭМБАГДАХГҮЙ ЦЭВЭРЛЭГЧДИЙН Машин бол шарсан чипс дээр тосолсон чипсийг зайлуулаарай.

Учир, шарсан шугамыг шарсан шугамууд нь ихэвчлэн тослогтой, тослог зэргийг өдөөж, үйлдвэрлэлийн шалыг эсэргүүцэж болно. Тиймээс, газрын тос хүлээн авах чичиргээ бүхий чичиргээний машин нь газрын тосыг чипс гадаргуугаас гаргаж, үйлдвэрлэлийн сайтыг цэвэр байлгахад тохиромжтой.

Илүү юу байна, чичирхийллийн явцад, Чипс нь foward хөдөлж, дараагийн үйл явцад ч хүргэдэг.

Хийн хөртж машин

Хөргөх конвейерийг агааржуулагчаар үлээж байна. Тиймээс чипс температурыг байгалийн хүчтэй салхинд хийсдэг. Энэ нь улирлын чанар, баглахаас өмнө чухал үйл явц юм. Бүрэн хөргөх чипс нь илүү их судтай бөгөөд илүү урт хугацаатай байх болно.

Нэмэлт загвар: Салхины хамгаалалт нь conveyor бүсээс салхилахаас зайлсхийх хэрэгтэй.

Хөргөлттэй конвинг дор хавтан ававал нь чипсээс нисгэгчийн тосыг авах нь нэмэлт сонголтыг авах нь сонголттой байдаг.

Төмсний чип амтлагч машин

Хурдны төрөл улирлын чанартай амтлагч машин нь нунтаг улиралаар ажилладаг, халуун ногоотой чанарлаг, давс, мөн газрын тос шүрших гэх мэтээр тохируулж болно. Үйлдвэрлэлийн дагуу.

Чипс шугамын хувьд, Чипийг хөргөсний дараа, Барн нь кальцыг жигнэж, чипстэй хамт амтлагчаар холихын тулд чипсийг үргэлжилж, чипсийг жигнэсэн.

Болон гарц дээр, Нэмэлт амтлагч, хог хаягдал, хог хаягдлыг хүлээн авах боломжийг олгодог торон дизайнууд байдаг. Энэ загвараас болж, Чипс нь зөв хэмжээний амтлагч, гайхалтай амттай байдаг.

Автомат машиныг жинлэх замаар баглах, Дүүргэх, цүнх хийх

Чипсийг автоматаар хуванцар уутанд хийх, Авто чипс баглаа боодлын машин нь хамгийн тохиромжтой сонголт юм. Ердийн, Авто чипс баглаа боодлын машин нь цахилгаан шат багтана, Олон толгойтой Weigher, хавтгай хэлбэр, ЦАГИЙН ХУДАЛДААНЫ ТӨЛӨВЛӨГӨӨНИЙ ТӨЛӨВЛӨГӨӨНИЙ ТӨЛӨВЛӨГӨӨ, ба эцсийн бүтээгдэхүүн конвейер.

Ба, Сав баглаа боодол, азотын функц нь урт бариултай амьтантай чипсийг хадгалах бөгөөд тээврийн явцад хамгаалалт өгөх шаардлагатай.

Илүү юу байна, Чан баглаа боодлын машин нь өндөр үр ашигтайгаар давуу талтай байдаг, үнэн зөв жинтэй, чипс үйлдвэрлэлийн шугамаар тасралтгүй ажиллах.

Төмсний чипс үйлдвэрлэгч машин параметр

Бүрэн автоматаар төмсний чипс үйлдвэрлэлийн шугам DT-PC-500, Лавлахад 450-500кг / цаг.

| Нэр | Эрчим хүч ердийн клуб | Давуу чанар |

| Бункер бүхий цахилгаан шат | 0.75 кВт | 380V 50hz 3ph, тохируулах боломжтой |

| Төмс угаах, хальслах машин | 4.75 кВт | 380V 50hz 3ph, тохируулах боломжтой |

| Конвейерийг сонгох | 0.75 кВт | 380V 50hz 3ph, тохируулах боломжтой |

| Төмсний чип таслагч машин | 1.1 кВт | 380V 50hz 3ph, тохируулах боломжтой |

| Банн машин машин | 70 кВт | 380V 50hz 3ph, тохируулах боломжтой |

| Дээврийн хэрэгслийг чичирхийлэх | 1.5Kw | 380V 50hz 3ph, тохируулах боломжтой |

| Агаарын хөргөлтийн шингэн алдалт шугам | 15 кВт | 380V 50hz 3ph, тохируулах боломжтой |

| Литататор нь шарсан махны өмнө дамждаг | 0.75 кВт | 380V 50hz 3ph, тохируулах боломжтой |

| Төмсний чипс хайруулын машин | 204.5 кВт | 380V 50hz 3ph, тохируулах боломжтой |

| Деекингийн машиныг vibrate | 1.5 кВт | 380V 50hz 3ph, тохируулах боломжтой |

| Агаарын хөргөлттэй хатаах шугам | 8 кВт | 380V 50hz 3ph, тохируулах боломжтой |

| Eeleleltator амтлагч | 0.75 кВт | 380V 50hz 3ph, тохируулах боломжтой |

| Амтат машин | 1.5 кВт | 380V 50hz 3ph, тохируулах боломжтой |

| Бүрэн автомат төмсний чипс баглаа боодлын машин | 6.5Kw | 380V 50hz 3ph, тохируулах боломжтой |

Төмсний чипс шугам үйлдвэрлэгч

Хайруулын машины үйлдвэрийн давуу тал

Нэг цэгийн хүнсний машин үйлдвэрийн

30 жил Р&D түүх

Тогтвортой машин гүйцэтгэл

Цаг тухайд нь хүргэх

Баталгаа

12 Сарын чанарын баталгаа

Насан туршийн техникийн дэмжлэг, сэлбэг хэрэгслийн үйлчилгээ

Үйлчилгээ

Борлуулалтын дараах дэмжлэг ажиллаж байна, засвар үйлчилгээ.

Үйлдвэр дээр онлайн эсвэл офлайн үнэгүй сургалт

Хэрэглэгчийн үйлдвэрт газар дээр нь суурилуулах

Шинэ бизнес төлөвлөгч нарт бизнесийн ерөнхий зөвлөгөө өгдөг.

Худалдан авагчийн улс руу хүргэх үйлчилгээ

Төмсний чипс үйлдвэрлэлийн шугамын үнэ

Техникийн инженерийн Технологийн ТЕХНИКИЙН ТЕХНИКИЙН БАГ, БАРИЛГЫН ТӨЛӨВЛӨГӨӨГИЙН ТӨЛӨВЛӨГӨӨГИЙН ҮНЭГҮЙ ҮНЭГҮЙ, Бага үйлдвэрлэл, илүү сайн хэрэглэгчийн сэтгэл ханамжтай байх. Түүнээс гадна, Бид өөрсдийн бизнесийнхээ зөв шийдэлтэй харилцагчийн хэрэгцээнд хариу үйлдэл үзүүлдэг.

Та одоо багахан шийдэл, ишлэлд хүрэхийн тулд та манай багтай холбоо барихаар баяртай байна.

Холбоотой машинууд

Францын шарсан үйлдвэрлэлийн шугам, гадил жимсний чипс үйлдвэрлэх шугам, пенавт хайруулын шугам. тасралтгүй шарагч, бага хэмжээний төмсний чип коп үйлдвэрлэлийн шугам