Friggitrice continua per friggitrice di patatine di pollo

Friggitrice continua è un sistema di frittura automatico e continuo utilizzato nella linea di produzione di pepite di pollo automatico, linea di frittura a pellet, linea di produzione di patatine fritte, linea di produzione di patatine automatiche, Linea di banane patatine ecc..

Capacità: 100Kg/H a 1500 kg/h, e personalizzato in base al requisito.

Fonte di riscaldamento: Elettricità, Gas/GPL, Diesel da scegliere

Materiali: Acciaio inossidabile per uso alimentare 304

Applicazione della friggitrice continua

La friggitrice continua è una macchina da frittura completamente automatica per realizzare un processo di frittura continua, Controllo della temperatura dell'olio, Tempo di frittura impostato, alimenti fritti e snack che si scaricano automaticamente. Dal momento che la macchina frittura consente di risparmiare notevolmente i costi di manodopera e migliora l'intera efficienza della linea di produzione. E per i suoi numerosi vantaggi, La macchina da frittura automatica è una scelta preferita per la linea di produzione di fabbrica alimentare.

Le friggitrici automatiche vengono utilizzate per i chip di frittura continua, noci, patate fritte, Namkeen, arachidi, anacardi, pelle di pesce, pelle di maiale, patatine di platano, patate fritte, patatine fritte, pepite di pollo, involtini primavera, pane puro ecc.

Oltretutto, L'attrezzatura a frittura continua svolge un ruolo importante nella linea di produzione alimentare automatica, ad esempio linea di produzione di patatine fritte fritte surgelate automatiche, linea di lavorazione delle crocchette di pollo, Linea di frittura di hamburger, linea di produzione di patatine di banana, Linea di frittura a panna ecc.

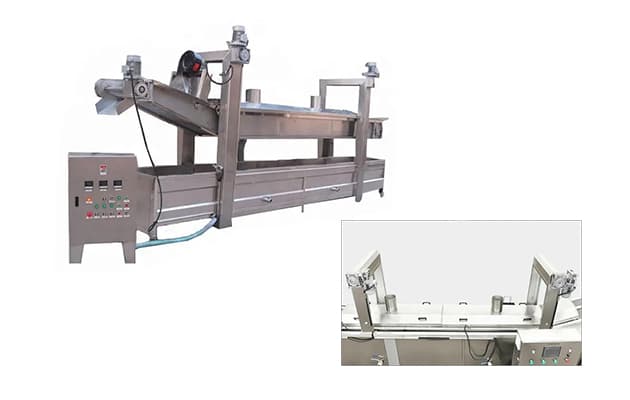

Introduzione alla macchina di frittura continua

Descrizione automatica della macchina friggitrice

L'attrezzatura a frittura continua continua è un sistema di frittura continua, Coprendo la trasmissione delle cinture per controllare il tempo, Cintura Evelavtion per la pulizia, Controllo e regolazione della temperatura dell'olio.

E la macchina della friggitrice è costruita con cinture a maglie a doppio strato per smettere. E le cinture sono normalmente personalizzate in base ai materiali di frittura.

Oltretutto, Friggitrice di riscaldamento esterno con grande capacità anche con sistema di demolizione residui e rifiuti, Sistema di ricarica del petrolio, Sistema di filtraggio e riserva dell'olio ecc..

Cosa c'è di più, La macchina da frittura non viene utilizzata da sola solo nei seminari o nella cucina centrale, ma abituato anche a lavorare continuamente nella linea di produzione alimentare automatica.

Specifiche continue di friggitrice industriale

Metodo di riscaldamento: Riscaldamento elettrico / Riscaldamento a gas / Riscaldamento diesel

Materiali della macchina: Per uso alimentare 304 materiali in acciaio inossidabile, migliore qualità fatta

Controllo della temperatura: Dispone di un sistema di controllo automatico della temperatura dell'olio

Temperatura di riscaldamento dell'olio: 0da ℃ a 300 ℃ (Fahrenheit da 32°F a 572.0 °F)

Capacità: 100Kg/h a 1500 kg/h e capacità personalizzata (in base ai modelli di friggitrice e alle materie prime)

Tipo e vantaggio automatico della macchina e vantaggio

Mini friggitrice continua

Mini Donut Frying Machine viene utilizzata per friggere le ciambelle, risciacquo, economico, biscotto di cincillà, involtini primavera, samosa ecc.

Mini frittura delle pepite di pollo può essere utilizzata per friggere le zampe di pollo, ali di pollo, patatine di patate dolci con pochi minuti di frittura.

Mini patatine friggitrice viene utilizzata per friggere patatine fritte, patatine fritte, patatine alla banana, Peanuts ecc.

Vantaggio

Un vantaggio superabile delle mini friggitrici è che possono essere personalizzati per fare cracker di gamberi, maccheroni cracker, Cracker di scorte di maiale con tempo di frittura variava in pochi secondi.

Oltretutto, È una scelta economica e continua per la produzione di alimenti per nuovi e piccoli e medie dimensioni.

Friggitrice per riscaldamento elettrico a macchina continua

La friggitrice per olio elettrico automatico è adatta alle pepite di pollo, Burger frittura, polpette, Cani di formaggio, arachidi, NET di anacardi, involtini primavera, samosa ecc.

Vantaggio

È più facile da pulire dopo la produzione.

E i riscaldatori riscaldano olio distratto, Risparmio energetico e olio riscaldati rapidamente.

Controllo della temperatura dell'olio più accurato per assicurarsi prodotti migliori con colore pari e alta qualità.

Friggitrice per riscaldamento a gas con macchina continua

Friggitrice per patatine a gas è adatto per friggere le patatine di banana, patatine di platano, patate fritte, involtini primavera, patatine ecc.

Vantaggio

Il riscaldamento del gas la macchina a frittura continua è un risparmio energetico e una scelta preferita in alcuni paesi e regioni che il gas è molto più economico dell'elettricità. Perciò, Il costo di produzione è molto ridotto.

Caratteristiche e vantaggio della friggitrice per chip continui

Tempo di frittura regolabile con le cinture del trasporto a doppio strato

Le cinture del trasportatore superiore e inferiore spingono il cibo fritto dall'ingresso all'uscita della macchina fritta. Perciò, Il tempo di frittura è regolabile impostando la velocità di trasporto.

La cintura superiore con scrapper potrebbe premere completamente i materiali galleggianti in olio e spingerlo in avanti. Di conseguenza, Il colore alimentare fritto è uniforme e la qualità è buona.

Le cinture del trasportatore sulla macchina friggitrice automatica sono personalizzate e in grado di sostituire in base alle esigenze di produzione. Per esempio, Abbiamo friggitrici costruite con cinture a maglie, cinture a catena, cinghia di filo flessibile piatto in acciaio inossidabile. Secondo le caratteristiche delle materie prime.

Sistema di sollevamento automatico Easy pulizia

Le friggitrici continue sono costruite con un sistema di sollevamento automatico. Per sollevare la copertura superiore e il trasportatore si alza dopo la produzione. Rende il funzionamento della pulizia e della manutenzione più semplice e conveniente.

Sistema di filtraggio dell'olio (Opzionale) Migliorare la qualità dell'olio

In qualche situazione che le materie prime sono pepite di pollo, Bispette di pesce, panini primaverili impanati ecc, Il pane o i rifiuti potrebbero lasciarsi nell'olio durante il processo di frittura. Quindi il sistema di filtraggio dell'olio è necessario per filtrare online l'olio o avviare il filtro dell'olio dopo la produzione e i prodotti fritti sono di qualità migliore.

Mentre si trova in una linea di produzione più grande per friggere i patatine, arachidi, patatine fritte, patate fritte, ecc, Il sistema di filtro dell'olio migliora notevolmente la qualità dell'olio.

Sistema auto -pulito (Opzionale) Migliorare la qualità del prodotto

Per migliorare la qualità del prodotto, Il sistema auto -pulito è un'opzione. Rimuove il lavandino dei rifiuti verso il basso durante la produzione. Ciò potrebbe prolungare la vita dell'utilizzo dell'olio e assicurarsi anche della qualità del prodotto fritto.

Parametro automatico della macchina friggitrice

Riscaldamento elettrico Macchina di frittura continua

| Modello | Capacità (Materia prima) | Energia | Peso | Dimensione della friggitrice | Temperatura dell'olio |

| DT-CF-3500E | 500kg/h | 80kw | 1000kg | 3500*1200*2400mm | 0-300 ℃(Fahrenheit da 32°F a 572.0 °F) |

| DT-CF4000E | 600kg/h | 100kw | 1200kg | 4000*1200*2400mm | 0-300 ℃(Fahrenheit da 32°F a 572.0 °F) |

| DT-CF-5000E | 800kg/h | 120kw | 1500kg | 5000*1200*2400mm | 0-300 ℃(Fahrenheit da 32°F a 572.0 °F) |

| DT-CF-6000E | 1000kg/h | 180kw | 1800kg | 6000*1200*2400mm | 0-300 ℃(Fahrenheit da 32°F a 572.0 °F) |

| DT-CF-8000E | 1500kg/h | 200kw | 2000kg | 8000*1200*2600mm | 0-300 ℃(Fahrenheit da 32°F a 572.0 °F) |

| Osservazione: La capacità finale per ciascun modello è variata in base al materiale fritto e il tempo di frittura richiesto. | |||||

Riscaldamento a gas Macchina fritta continua

| Modello | Capacità (Materia prima) | Consumo energetico | Peso della macchina | Dimensione friggi | Temperatura dell'olio |

| DT-CF-3500 | 500kg/h | 300,000 Kcal | 1200kg | 3500*1200*2400mm | 0-300 ℃(Fahrenheit da 32°F a 572.0 °F) |

| DT-CF-4000 | 600kg/h | 500,000 Kcal | 1500kg | 4000*1200*2400mm | 0-300 ℃(Fahrenheit da 32°F a 572.0 °F) |

| DT-CF-5000 | 800kg/h | 500,000 Kcal | 1700kg | 5000*1200*2400mm | 0-300 ℃(Fahrenheit da 32°F a 572.0 °F) |

| La capacità FINA per ciascun modello è varia in base al materiale fritto e al tempo di frittura richiesto. | |||||

Patatine friggitrice in vendita macchina patata continua

Friggitrici di chips potrebbe usare da solo, ma può anche usare con chip slicer, macchina disoleatrice, Macchina di raffreddamento e macchina da condimento per creare una linea di produzione di patatine continue, Linea di produzione di banane patatine ecc..

Possiamo personalizzare la soluzione di linea di produzione e raccomandare macchine adeguate in base alla capacità aziendale e allo spazio di fabbrica. Benvenuti a contattare il nostro team ora per ottenere una citazione dettagliata.

Come usare la macchina friggitrice con chip continua?

Dopo l'installazione e controllata la macchina da frittura industriale, pulito, Prova testata in fabbrica. L'utente può iniziare la produzione in base al proprio piano.

Tuttavia, Ecco un breve processo operativo che l'utente deve seguire dopo l'installazione.

- Acqua pulire il serbatoio dell'olio, frittura e cintura trasportatore, e asciuga l'umidità.

- Riempi l'olio direttamente dal lato su Fryer, oppure collegare il serbatoio di accumulo dell'olio alla friggitrice per pompare l'olio all'interno della friggitrice.

- Accendere la friggitrice e impostare la temperatura dell'olio e iniziare a riscaldare l'olio l'olio.

- Accendere il trasportatore per regolare la velocità adeguata del trasportatore per trovare il tempo di frittura più adatto per i prodotti.

- Per la ricarica del petrolio durante la produzione, potrebbe riempire manualmente l'olio / Oppure riempi l'olio dal serbatoio di accumulo dell'olio Accertarsi che il livello dell'olio tocchi le cinture superiori.

- Dopo la produzione, Attendere la temperatura dell'olio raffreddare sotto i 60 ℃ e pompare al serbatoio di accumulo dell'olio, Oppure vai a filtrare l'olio prima di andare al serbatoio di stoccaggio dell'olio.

Produttore di friggitrice continua

Garanzia

12 Mesi di garanzia di qualità

Servizio ricambi a costo netto

Servizio

Assistenza post-vendita in funzione, manutenzione.

Formazione gratuita on line o off line in fabbrica

Installazione on-site presso lo stabilimento del cliente

Consulenza aziendale generale per il nuovo business planner.

Servizi di consegna nel paese dell'acquirente

Fritta e patatine correlate

Friggitrice a cestello per friggitrice, linea di produzione di patatine di tipo batch, linea per friggere le arachidi, linea di produzione di cincillà