Patatine fritte francese congelata pianta di lavorazione fritte automatiche

francese linea di produzione di patatine è una soluzione di produzione automatica e avanzata sulla lavorazione della patata in patatine fritte.

Impianto di lavorazione delle patatine fritte automatiche contiene la macchina per lavare e sbucciare le patate, macchina per cutter fritte francese, macchina per sbollentare, macchina di disidratazione, macchina friggitrice fritte francese, macchina disoleatrice, macchina di raffreddamento, congelatore veloce, Macchina da imballaggio automatico e le sue apparecchiature ausiliarie.

Applicato a: Patatine fritte, patatine dolci, patatine di piantaggine lunghe, patate fritte, patatine fritte fresche, patatine fritte congelate, patatine di platano ecc.

Capacità: 50-100kg/h, 200-250kg/h, 350-400kg/h, 500kg/h, 1000kg/h, 1500kg/h, 2000kg/h e capacità personalizzata.

Applicazione della linea di produzione fritte congelata

Patatine fritte congelate che producono macchina è una soluzione avanzata per i produttori di patatine fritte congelate. Nessun watter è una linea di produzione automatica di patatine di patatine per patatine per le più grandi patatine fritte, o linea di produzione di patatine fritte congelate su piccola scala per fabbrica di medie dimensioni o nuova fabbrica di patatine francesi. Le nostre piante di lavorazione delle patate consentono agli investitori di buoni rendimenti riducendo notevolmente il lavoro, Miglioramento della qualità del prodotto, fornire produttività e quota di mercato.

La macchina per fare patatine congelati è anche popolare tra i produttori di alimenti per snack che vogliono che la linea faccia vari patatine, come patatine, patatine di platano, patatine di patate dolci ecc. E a causa della stagionalità delle materie prime, Hanno bisogno di una linea di produzione per la produzione fuori stagione per produrre altri prodotti.

Linea di produzione di patate congelate Introduzione

Descrizione della linea di produzione fritte fritte congelate

La macchina per patatine fritte commerciali è una linea di produzione completa che copre il lavaggio e la peeling di materie prime, macchina per sbollentare, Cutter di patate, friggitrice fritta francese, congelatore veloce, MACCHINA AUTOMATICA E BASSEGGIO.

E personalizziamo l'impianto di lavorazione delle patate per soddisfare diverse dimensioni delle imprese. Perciò, Abbiamo una linea di produzione di patatine fritte semi automatiche per capacità 50 kg all'ora ma anche linea di produzione di patatine francese su piccola scala con produzione 100 kg all'ora, e la produzione di patatine fritte completamente surgelate completamente automatiche fino a 2000 kg all'ora. Oltretutto, Personalizziamo le patatine fritte che creano la macchina con la capacità necessaria per il cliente.

Linea di produzione di patatine francese per le specifiche di vendita

Metodo di riscaldamento: Riscaldamento elettrico / Riscaldamento a gas

Materiali della macchina: Per uso alimentare 304 materiali in acciaio inossidabile, migliore qualità fatta

Temperatura di riscaldamento dell'olio: 0da ℃ a 300 ℃ (Fahrenheit da 32°F a 572.0 °F)

Capacità: 50Kg/H a 2000 kg/h (la capacità maggiore può essere personalizzata)

Requisiti di spazio in fabbrica: Possiamo personalizzare la linea di produzione in base alle dimensioni della fabbrica e alla planimetria.

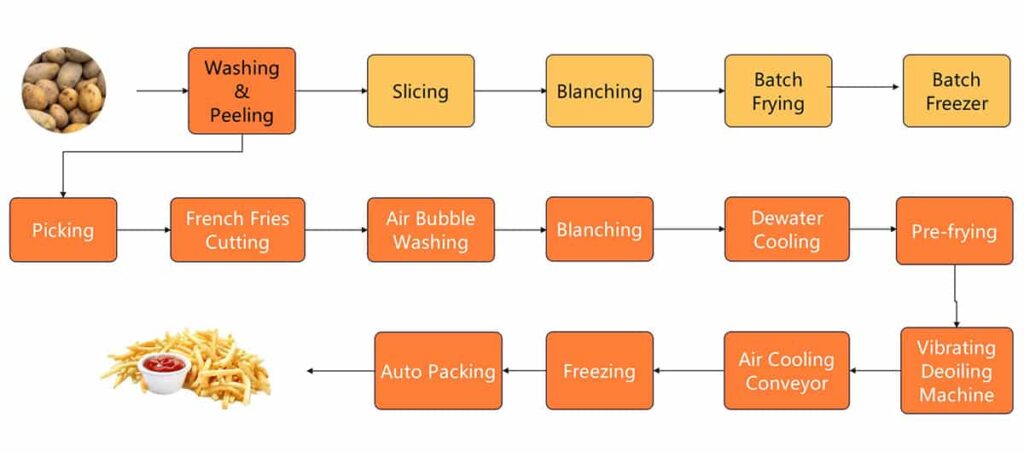

Diagramma di flusso macchina fritte completamente automatico

Include la linea di produzione di patatine fritte su piccola scala semi-automatico e completamente automatico flusso di elaborazione della linea di produzione di patatine fritte.

Caratteristiche della macchina fritte francese

Pelapatate

Questo è il lavaggio e la peeling della macchina continua lavaggio, peeling e scarico.

Perché i pennelli irregolari e ondulati sono composti da una pennello setole rigido e una spazzola smerigliata che consentono di sbucciare completamente le patate.

Oltretutto, la pelatrice di tipo sprial spinge la patata in avanti e scarica dall'altra estremità ai nastri trasportatori di raccolta prima del processo di affettatura.

Inoltre, è adatto per lavare e sbucciare le patate, patata dolce, manioca, zenzero, cipolla, carote ecc.

Macchina per tagliata a patate fritte francese elettrica

La macchina da taglio delle patatine fritte di patate è un taglia patatine commerciali con alta uscita. E bastoncini francesi taglia 7*7mm, 8*8mm, 10*10mm, e il fatto su misura può essere modificato regolando la lama.

La macchina per taglieri di patatine francese è adatta anche per altre verdure di radice, come le carote, manioca, ecc.

Il prodotto finale è liscio, uniforme e privo di pause.

Sbollentare le patate prima di friggerle

Questa è una macchina sbiancante per proteggere il colore dei bastoncini francesi e rimanere il gusto di beni.

Il tempo di ramificazione delle patatine è circa 5 a15 minuti a una temperatura dell'acqua calda di 70 ℃ (158.0 °F). E la cinghia di maglia in acciaio inossidabile è con regolazione della velocità di conversione della frequenza, Quindi il tempo e la velocità sbiancanti sono regolabili.

Ci sono una macchina di ramificazione continua con riscaldamento a gas e macchina di ramificazione continua con riscaldamento elettrico per la scelta del cliente.

Macchina per la disidratazione delle patate

La macchina per il raffreddamento dell'aria rimuove l'acqua e raffredda la temperatura dei bastoncini di patate ramificate prima di friggere. Accorcia il tempo di frittura e garantisce il gusto di qualità delle patatine fritte.

E per avere un effetto migliore, è necessario utilizzare una macchina disoleatrice vibrante prima del nastro trasportatore di essiccazione e disidratazione all'aria.

macchina friggitrice fritte francese

Per impianti di patatine su piccola scala, La frigorifera del tipo di cesto o la macchina da frittura rotonda è la scelta ideale per la capacità inferiore a 200 kg all'ora.

Tuttavia, per un impianto di produzione di patatine completamente automatico francese, la macchina a frittura continua è la migliore opzione per mantenere il tempo di frittura continuo a lavorare con una maggiore capacità e meno fatiche. La migliore macchina delle patatine francese è materiali in acciaio inossidabile e il suo tempo di frittura è regolabile e regolabile alla temperatura dell'olio.

Oltretutto, Possiamo anche personalizzare la friggitrice per automatizzare il processo di ricarica del petrolio, riciclo di petrolio, Sistema di filtraggio e auto -pulizia dell'olio. Ciò migliorerà notevolmente l'efficienza della produzione, prolunga l'uso di petrolio e le patatine francesi di qualità Better.

Macchina per la disoleazione

La macchina per deoiling vibrante è necessaria per rimuovere l'olio sulla superficie delle patatine fritte dopo la frittura.

Perché, I bastoncini francesi fritti dalla linea di frittura portano normalmente alcuni oli che causano il prodotto oleoso e possono nutrare il pavimento di produzione. Perciò, la macchina vibrante con piastre riceventi olio è utile per disoleare l'olio dalla superficie dei trucioli e mantenere pulito il sito di produzione.

Cosa c'è di più, durante il processo di vibrazione, i chip si muovono in avanti e si diffondono anche al processo successivo.

Macchina di raffreddamento

Il trasportatore di raffreddamento è installato con ventilatori che soffiano per le patatine fritte francesi. Pertanto la temperatura superficiale scende in particolare per il vento forte naturale. Questo è un processo importante prima del processo di congelamento rapido.

E la piastra di ricezione dell'olio sotto il trasportatore di raffreddamento è facoltativo per ricevere l'olio lasciato cadere dalle patatine fritte.

Congelatori del tunnel del congelatore fritte

Patatine fritte francese Il congelatore rapido è applicabile a congelare grandi quantità di patatine fritte in brevi periodi di tempo senza causare lo sviluppo o il prodotto di blumps..

Temperatura centrale del materiale da alimentare:<20 C

Temperatura di scarico: -18℃

Tempo di congelamento: 15 da min a 45 minuti.

Macchina confezionatrice automatica con pesatura, Riempimento e realizzazione di sacchetti

Mettere le patatine fritte francese congelate in sacchetto di plastica automaticamente, Il ripieno e la tenuta automatica della custodia sono la scelta ideale. Include ascensore, pesatrice multitesta, flatform, dispositivi per la produzione di sacchetti con funzione di stampa della data, e un trasportatore del prodotto finale.

Cosa c'è di più, la confezionatrice per trucioli presenta il vantaggio di un'elevata efficienza, pesatura accurata, e lavorare continuo con la linea di elaborazione delle patatine francese.

Parametro della linea di elaborazione delle patatine francese

Elenco di macchine fritte francese congelate come di seguito solo per riferimento. E siamo in grado di personalizzare la linea di elaborazione delle patatine in base al layout della fabbrica di clienti, voltaggio, varietà di prodotti finali, Tipo di imballaggio ecc.

| NO. | Nome macchina | Quantità | Unità | Tasso di tensione |

| 1 | Ascensore | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 2 | Macchina per lavare e pelare le patate | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 3 | Seleziona la cintura del trasporto | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 4 | Cutter di patate | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 5 | Sollevamento spray del secchio | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 6 | Macchina da raccogliere fritti francesi non qualificati | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 7 | Macchina risciacquo | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 8 | Macchina sbiancante | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 9 | Disidrator di vibrazione | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 10 | Essiccatore raffreddato ad aria | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 11 | Ascensore | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 12 | Macchina frittura continua | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 13 | Macchina deoilingg vibrante | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 14 | Essiccatore raffreddato ad aria | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 15 | Patatine fritte che diffondono macchina | Impostato | 380V 50Hz 3Ph può essere personalizzato | |

| 16 | Congelatore | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

| 17 | Macchina da imballaggio | 1 | Impostato | 380V 50Hz 3Ph può essere personalizzato |

Patatine fritte che producono macchine

Vantaggio

Fabbrica unica di macchine alimentari

30 anni R&Storia D

Prestazioni stabili dei macchinari

Consegna puntuale

Garanzia

12 Mesi di garanzia di qualità

Supporto tecnico per tutta la vita e servizio di pezzi di ricambio

Servizio

Assistenza post-vendita in funzione, manutenzione.

Formazione gratuita on line o off line in fabbrica

Installazione on-site presso lo stabilimento del cliente

Consulenza aziendale generale per il nuovo business planner.

Servizi di consegna nel paese dell'acquirente

Prezzo della macchina fritte francese

Disponiamo di un team di ingegneri tecnici professionisti e di un team di sviluppo del prodotto per aggiornare la nostra linea di produzione per una maggiore efficienza, meno produzione e migliore soddisfazione dell'utente. Oltretutto, comprendiamo e rispondiamo rapidamente alle esigenze dei clienti con la giusta soluzione per il loro business.

Ora sei il benvenuto a contattare il nostro team per un costo degli impianti di produzione di patatine francese..

Qual è la migliore patata usata per la linea di patatine fritte congelate?

Shepody è una cultivar di patate dalla pelle bianca che ha avuto origine nel New Brunswick, Canada e viene utilizzato per bollire, cottura al forno, e frittura francese. È dRy Matter 19-21%, Contenuto di zucchero a basso riduzioneoc 0.4% , particolarmente adatto per la lavorazione della frittura.

Cosa c'è di più, Le patatine fritte nei fast food e le patatine nei supermercati sono prodotte in serie nelle fabbriche. Il ben fatto, Shepody dagli occhi chiari è facile da sbucciare durante la produzione, e le patatine risultanti e patatine fritte che mostrano raramente buchi e cicatrici.

Perciò, Shepody è tipi di patate ideali per la produzione di patatine fritte congelate.

Macchine correlate

Macchine per patatine, linea di produzione di patatine di banana, linea di frittura dei penauti. friggitrice continua, linea di produzione di patatine su piccola scala