Introduction

In the fast-paced modern world, instant noodles have become a staple food for millions, offering convenience, affordability, and taste. Behind this global phenomenon lies a sophisticated manufacturing ecosystem centered around the instant noodles production line. This article delves into the critical aspects of instant noodles production, including key manufacturers, pricing dynamics, and cutting-edge solutions. Whether you’re a startup looking to enter the market or an established player seeking upgrades, understanding the components and features of a high-efficiency production line is vital. Finally, we’ll highlight why DT Food Machine stands out as a leading provider of innovative and reliable solutions.

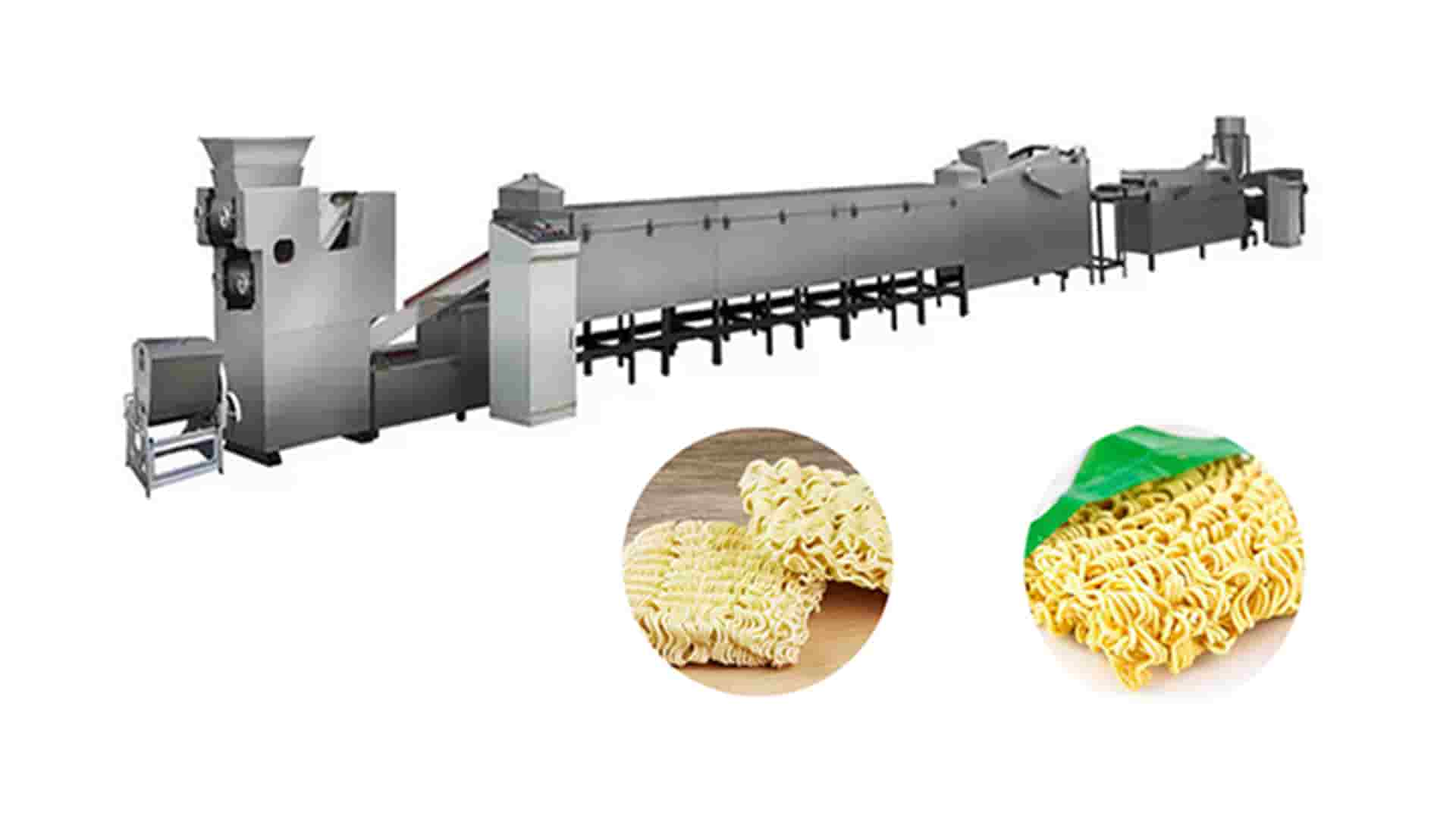

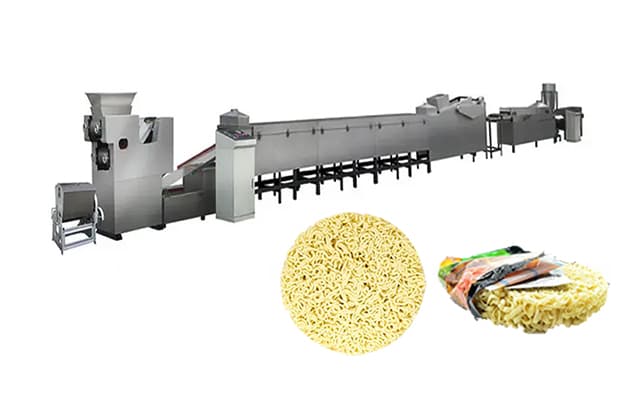

I. The Components of an Instant Noodles Production Line

A state-of-the-art instant noodles production line integrates multiple stages, from raw material processing to final packaging. Here’s a breakdown of its core components:

1.Raw Material Preparation System

- Flour Mixing & Blending: Automated mixers ensure precise ratios of wheat flour, starch, and additives.

- Water Treatment: Advanced filtration and purification systems guarantee water quality for dough consistency.

2.Dough Processing Unit

- High-Speed Mixers: Dual-axis mixers with variable speed controls for homogeneous dough.

- Sheet Rolling Machines: Adjustable rollers produce uniform noodle sheets with thickness control.

3.Noodle Forming & Cutting

- Extrusion Molds: Customizable dies for various noodle shapes (curly, flat, round).

- Laser Cutting Technology: Precision cuts minimize waste and ensures uniform lengths.

4.Cooking & Drying Systems

- Steam Cooking Chambers: Rapid steaming (80–100°C) to gelatinize starch.

- Oil Fryers (or Hot Air Dryers): Energy-efficient fryers with oil filtration or air impingement dryers for crispiness.

5.Cooling & Seasoning Application

- Air Coolers: Rapid cooling to halt cooking processes.

- Seasoning Drum Coaters: 360° coating for even flavor distribution.

6.Packaging Solutions

- Automated Packing Machines: Nitrogen-flushing and vacuum-sealing options for extended shelf life.

- Case Packers: Robotic arms for palletizing and logistics optimization.

Key Features of Modern Production Lines

- IoT Integration: Real-time monitoring via sensors for predictive maintenance.

- Modular Design: Scalable modules for capacity adjustments (e.g., 50–500 packs/min).

- Energy Efficiency: Heat recovery systems in fryers reduce energy costs by 30%.

- Food Safety Compliance: Stainless steel 304 construction, CIP (Clean-in-Place) systems.

II. Leading Manufacturers & Market Trends

The global instant noodles production line market is dominated by players in China, Japan, and Southeast Asia. Key manufacturers include:

- DT Food Machine (China): Known for customizable turnkey solutions.

Pricing Factors

- Capacity: Lines range from 50,000(small−scale)to5 million (industrial).

- Automation Level: PLC-controlled systems vs. semi-automatic models.

- Customization: Tailored designs for regional tastes (e.g., spicy, cup noodles).

- After-Sales Support: Training, spare parts, and warranties impact long-term costs.

Market Trends

- Healthier Options: Reduced-fat noodles, fortified with vitamins/fiber.

- Sustainability: Eco-friendly packaging and energy-saving technologies.

- Premiumization: Gourmet flavors and organic ingredients for niche markets.

III. DT Food Machine: Your Trusted Partner

Why Choose DT Food Machine?

- Innovation & Customization

- Patented Technologies: Oil-saving fryers and high-speed cutters.

- Bespoke Solutions: From pilot-scale to 1,000 tons/day capacities.

- Quality & Compliance

- ISO 22000 & CE Certifications: Ensures food safety and EU standards.

- Durable Materials: Food-grade stainless steel for hygiene.

- Cost-Efficiency

- Energy-Saving Designs: Heat recovery reduces operational costs.

- Competitive Pricing: Direct-from-factory models without intermediaries.

- Global Support

- 24/7 Technical Service: Local teams in 50+ countries.

- Training Programs: Hands-on workshops for operators.

Case Study: Success in Southeast Asia

A DT Food Machine client in Vietnam increased production by 40% after installing a fully automated line. The energy-efficient fryer cut oil consumption by 25%, while the seasoning drum improved flavor consistency. ROI was achieved within 18 months.

IV.Conclusion

Investing in a high-quality instant noodles production line is a strategic move for businesses aiming to capitalize on the evergreen demand for convenience foods. By understanding the components, market trends, and choosing the right partner like DT Food Machine, you can achieve scalability, cost efficiency, and compliance.

Ready to Upgrade Your Production?

Contact DT Food Machine today for a free consultation and quote. Explore our designed to elevate your instant noodles business!