Mini Potato Chips Plant Small Scale Potato Chips Machine

Mini Potato Chips Plant is potato chips making machine for small business, with output of 30kg/h, or 50kg/h, upto 100kg per hour.

Small scale potato chips machine has advantage on reducing manpower, producing various chips, and little investment with attractive returns. Therefore, it is popular for small potato chips manufacturers.

Application: Making potato chips, sweet potato chips, french fries, plantain long chips, banana chips etc.

Material: Food Grade Stainless Steel 304

Capacity: 30kg per hour, 50kg per hour, upto 100kg/h

Mini Potato Chips Plant Application

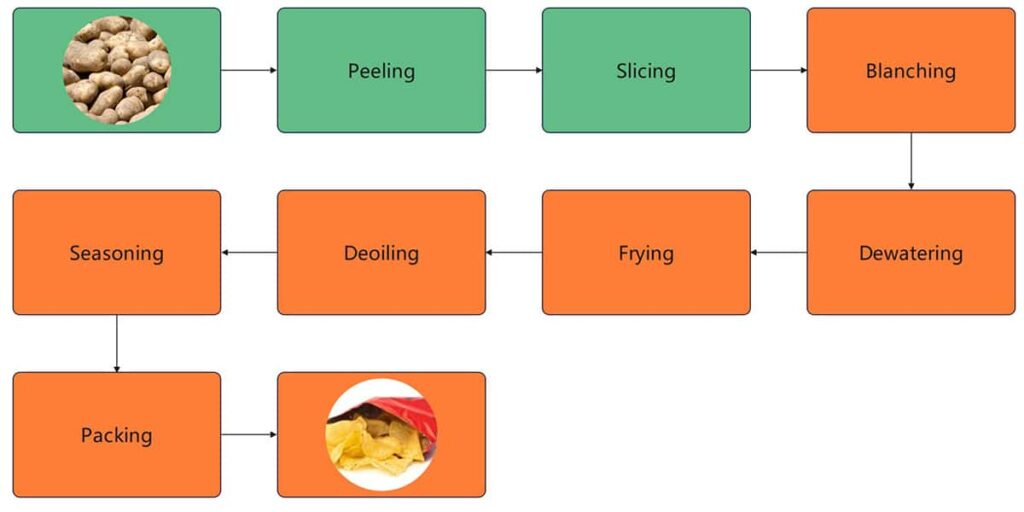

Small scale potato chips making machine uses the potatoes with low water rate and high starch content as raw materials. And through washing, peeling, slicing, frying process, potato chips production line turns the raw potato into delicious and crispy potato chips.

Besides, small chips making machine can also be customized to make finger chips, banana chips, sweet potato chips, etc. Therefore, small potato chips machine can allow snack manufacturers to produce various chips products at minimum cost.

Therefore, mini potato chips plant is quite popular among small business chips manufacturers. Not only because the production line saves manpower, but also has better return on investment.

Potato Chip Plant Introduction

Small Potato Chips Making Machine Description

Semi automatic potato chips making machine is potato chips making machine for small business, with output of 30kg/h, or 50kg/h, upto 100kg per hour. And the potato chips production is flexible to various product type, and customizable according to client requirement and factory space.

Normally, the small potato plant includes potato chips peeler, industrial chip cutter, vegetable blancher, potato dewatering machine, potato chip fryer equipment, centrifugal deoiling machine, potato chip seasoning machine and potato packing equipment. While customer could customize their own chips plant according to their need and capacity requirement.

Small potato chips machine is made of food grade stainless steel material. And semi-auto potato chip production line has separate control on each machines, so that worker could run and stop each machine according to production need. Therefore, small potato chips machine helps chips manufacturer to improve production efficient and ensure food safty.

While to meet different business demand, we have designed semi-automatic potato chips production line with capacity 30 to 50kg/h or 50 to 100kg/h. But also we designed potato chips fully automatic machine with capacity upto 500KG/H and higher capacity can be customized.

Small Potato Chips Plant Specification

Heating Method: Electric heating / Gas Heating

Machine Materials: Food grade 304 stainless streel materials, best quality made

Capacity: 30kg per hour to 100kg per hour, customizable

Oil Heating Temperature: 0℃ to 300℃ (Fahrenheit 32°F to 572.0 °F )

Ratio of potato and potato chips: 3 to 3.5 : 1 for references.

Recommendation: Blanching time: 60 to 90 seconds at water temperature: 90 to 95℃. While, frying time: 3 to 4 minutes, at oil frying temperature: 170-180℃.

Factory space requirement: We can customized the production line based on the factory size and floor plan.

Potato Chips Processing Plant Flow Chart

Potato Chips Processing Line Features

Peeler Machine Potato

This is professional potato peeler machine made of food grade stainless steel material. And it is not suitable for potato with various sizes, and also suitable for sweet potato etc.

Potato washer and peeler machine removes potato dirty and thin skin completely and efficiently, at peeling rate upto 98%.

This potato peeling machine is also simple to operate and clean. It works at batch peeling and worker could load batch potato and start cleaning while peeling. And worker can stop the machine when the peeling effect is satisfactory. Therefore, this is good to use in semi-automatic potato processing plant.

Slicer Machine Potato

Electric potato slicer is suitable for cutting potato into slices. And also it can use for cutting banana chips, sweet potato chips, onion rings and other roots.

Chips thickness can be adjustable and chips slices are uniform in size.

Besides, there are four inlets to feed the raw materials.

Blanching Machine for Potatoes

Potato blanching machine cook the potato chips in water to keep the original flavor and fresh color. The recommended water temperature 90 to 95℃ at 60 to 90seconds.

However, the blanching time and water temperature is controllable automatically and adjustable according to different materials need.

For heating method, we have electric blanching machine and also gas heating vegetable blanching machine.

Potato Chip Dewatering Machine

Potato dewatering machine removes water on surface of potato chips after blanching by high speed centrigugal dewatering method.

And centrifugal dewatering machine shall be fixed to solid ground to use, and it also has shockproof devices to keep stable working.

Potato Fryer Machine Price

Potato frying machine is basket type for small potato plant. And the frying time and temperature is controllable and adjustable based on needs. The recommended frying time is 3 to 4 minutes at oil temperature 185℃.

And there is electric deep fryer and gas heating deep fryer to choose. Besides, this basket type frying machine is suitable for capacity 30 to 50kg an hour and 100kg an hour.

What is more, we also have round pot frying machine and mini continuous frying machine for larger capacity 100kg an hour with higher efficiency and labor saving.

Centrifugal Deoiling Machine

Potato chips deoiling machine is same working principle as potato chips dewatering machine. They all adopt centrifugal spinning to remove oil on potato chips after frying. Therefore, the chips is not oily and better taste and have long shelf life.

The de oiling machine is also having shockproof devices and spinning speed is adjustable according to need.

Potato Chip Seasoning Machine

Potato Chips Seasoning Machine is batch type seasoning process, to mix evenly the potaot chips with salt and spices.

Advantage of this seasoning machine is low breaks rate and suitable for almost all kinds of chips, onion rings, corn flakers, crackers, dried fish, fried beans etc.

While to add salt or spices automatically or spray liquid, we can customize to add the auto spices feeder on this seasoning machine.

Packing Machine for Chips

This is semi automatic potato chips packing machine without weighing function. It has filling machine, bag making and sealing machine. Therefore, the worker needs to weigh the chips before load each batch to bukets on this packing machine.

It has nitrogen filling inlet so that can do nitrogen filled packages.

Potato Chips Maker Machine Parameter

We have potato production line with 30kg an hour, 50kg an hour and upto 100kg an hour potato processing line. We an also customize the production line machine and capacity according to requirement.

| Model | DT-PC-30 | DT-PC-50 | DT-PC-100 |

| Raw Input | 100 | 200 | 400 |

| Chips Output | 20-30KG | 30-50KG | 50-100KG |

| Voltage | 380V / 220V | ||

Mini Potato Chips Plant Manufacturer

Advantage of frying machine factory

One-stop food machinery factory

30 years R&D history

Stable machinery performance

On time Delivery

Guarantee

12 Months Quality Guarantee

Whole life technical support and spare part service

Service

After-sale support in operation, maintenance.

Free Training on line or off line at factory

Onsite installation in Customer’s factory

Overall business advises for new business planner.

Delivery services to buyer’s country

Mini Potato Chips Making Machine Price

We have professional technical engineer team and product develope team to updgrating our production line for higher efficency, less production and better user satisfactory. Besides, we understand and quick respond to customer needs with the right solution to their business.

You are most welcomed to contact our team now for a small scale potato chips production line.

Related Machines

Automatic potato chips production line, French fries production line, banana chips production line, penauts frying line. continuous fryer, basket type deep fryer, round pot automatic fryer, continuous frying machine.