Ice Cream Wafer Cone Machine Ice Cream Cone Machine

Ice cream wafer cone machine is a commercial ice cream cone machine. To meet different demands on ice cream cone shapes and sizes, the wafer cone machine is normally customized for baking cake cup, bowl cone, torch single cone, torch shape double cone,ice cream nut cone, flower ice cream cones etc.

Capacité:100-6000pièces/h

Prix: Meilleur prix, approvisionnement direct de l'usine avec la plus haute qualité

Source de chauffage: Chauffage électrique /Gaz (LNG or LPG)

Ice Cream Wafer Cone Machine Application

Ice cream wafer cone machine is professional cone baking machine, customized for different shapes and sizes of ice cream cones. We have ice cream maker for home use, ice cream shop use, and ice cream factory use.

For the popular ice cream cones, there are various types, such as waffle cones, wafer cones, and sugar cones. Each with their own flavor, texture, and ingredients.

What is a wafer cone?

Ice cream wafer cone is a wafer-style cone which is light, golden-brown, neutral-flavored with a crisp texture. The wafer cones obtain the lowest sugar content. And they are baked inside cone-shape mold, and no chance of ice cream leaking through the bottom.

What is best ice cream cone maker?

The best ice cream cone making machine needs to bake wafer cones with various shapes and sizes, but also make sure the beautiful appearance and uniform shapes. Alors que, to meet market demand, DT wafer cone maker has different types and model capacities as following:

Semi-auto wafer cone making machine

We design the cones machine for home use or cone vendor business. It has different models capacity ranged from 100pieces an hour to 1800 morceaux par heure.

En plus, It is easier to use for new user without any machine operation experience and it has less maintaince cost.

For these models, we design the electric heating baking machine.

Machine à cornets de glace automatique

The whole process of pouring flour paste to baking molds, baking and discharge cream cones automatically.

While the baking temperature and time is preset in our factory before delivery and the parameters are adjust to reset by customer according to their need.

And capacity of each model ranged from 1800pcs/h to 6000pcs/h. For this model, we design the electric heating ice cream cone machine

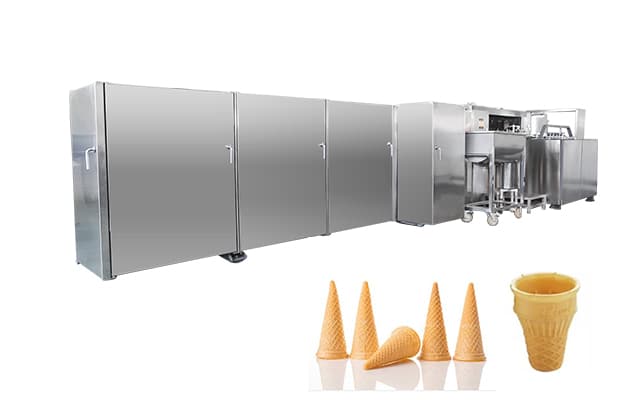

Fully automatic production line

Le fully automatic ice cream cone line is suitable for use in ice cream factory with production running 24hours per day to meet the huge market demand.

Production capacity is over 6000pcs/h and we customized the production line model based on wafer cones design and daily capacity requirement.

For this model, we design the gas heating oven.

Semi-automatic Ice Cone Cone Machine Introduction

Le semi-auto cone machine includes forming/baking machine, batter feeding tray and spare parts addtional like waste removing knife and oil brusher.

Modèle: WC-DT-2, WC-DT-4, WC-DT-10, WC-DT-12, WC-DT-18, WC-DT-24, WC-DT-24C, WC-DT-32, WC-DT-32, WC-DT-40, WC-DT-60,

Capacité:100-1800pièces/h

Prix: Meilleur prix, approvisionnement direct de l'usine avec la plus haute qualité

Source de chauffage:Chauffage électrique

Voltage Rate: 220V 50HZ single phase for smallest model, and big model voltage rate 380V 50HZ 3Phase. Note amicale: Voltage change customized cost is calculated separately as customer demand.

Personnalisation:The machine is customized as per cone shapes and sizes. Cependant, each set of cone baking machine is customized for one size and one shape of cones only.

Semi-automatic Cone Maker Specification

Nom | Semi-automat Ice Cream Wafer Cone Making Machine | ||

Modèle | DT-WC4 | DT-WC10 | DT-WC40 |

Nombre de moules de cuisson | 4 | 10 | 40 |

Capacité | 100 morceaux par heure | 200 morceaux par heure | 1300 morceaux par heure |

Pouvoir | 3.6kW | 5kW | 12kW |

Tension | 380V 50 Hz triphasé | 380V 50HZ three phase | 380V 50HZ Three phase |

Dimension | 430*430*650mm | 760*600*1050mm | 800*700*880mm |

Poids net | 80KG | 200KG | 240KG |

Pictures of Ice Cream Cone Machine Baking Molds

Wafer Cone Making Machine Feature

Easy Install and Easy Operate with Less Maintaince Cost

In most cases, we pack whole machine into one package. Donc, to install the electric heating ice cream cone machine, you will need a person with electrical background or professional electrical engineer to connect machine to main power of your workshop or kitchen and start to use the machine.

The worker needs to feed batter paste to baking mold manually, pull down the handle on machine to close the baking molds. After after baking time is over, worker needs to pull up the baking molds to allow cones discharge from bottom and start next batch production. The operation is simple.

User shall follow the maintaince guide to take care of machine after daily production. Cependant, the easy wore spare part is heaters which might needs to change after using for almost a year. We normally supply addtional spare heater with delivery of wafer cone machine and we recommend customer to order more with machine as spares.

Separate Baking Control on Lower Baking Molds and Upper Molds

There is separate heating control for whole set of upper baking Molds and the other set of down baking molds. User shall set the baking temperature based on our factory trial test best result however, they can adjust according to their need. It is easy to set the data manually.

Customization Service

Wafer cones have various shapes , size and logo design from ice cream factory. Donc, DT wafer cone baking machine needs to customize the baking molds and its capacity to meet demand from diffrent customers.

Note amicale, Il est important pour notre utilisateur de parler avec notre équipe, Partage de la conception du produit final, taille et forme pour obtenir une solution finale.

En plus, the industrial voltage rate is not all same in each countries. Donc, we are able to customize the cone baking machine at factory before delivery to customer.

Convivial

The cone ice cream maker is very friendly to operator, especially user without technical and manchine operation experience. The operator could normally operate more than one machine at a time as they only needs to fill the batter paste to baking molds, close the molds for baking and open the molds to discharge ready baked cones.

How to use a Cone Machine ?

Even a cone maker is quite simple to use, each operator shall read and follow the Machine Operation Book provided in each order delivery. And here is basic process of using a cone baking machine:Place the ice cream wafer cone baking machine on flat ground. Connec the machine to your factory main power.

- Follow the manual book to double check each part of machine to ensure they are well assembly.

- Clean and preheat the machine. Please brush fat oil to all sides of baking molds for first time use of machine to avoid batter paste stick to baking molds. And please remove the waste on baking molds complete before next batch production. Friendly reminder,it is not allowed to use hard or sharp knife to clean the baking molds, to avoid damage on baking molds.

- Allumez la machine à pâtisserie. (Le temps et la température de cuisson sont préréglés avant la livraison, mais il est réglable sur le site de l'utilisateur en fonction de ses besoins en produits.

- Après la production, plug off the machine, et couper l'électricité. Clean baking machine according to User’le livre.

Adantage of DT Ice Cream Wafer Cone Making Machine Company

Over 30 Year Wafer Cone Machine Manufacturing and Development

Decades of production and upgrading of cone equipment, so that our users have a better experience. From the initial semi-automatic wafer cone machine, it was upgraded to the PLC controlled automatic wafer cone machine, and finally to the automatic tunnel wafer cone machine used by large ice cream factories. We have always been keen to adapt our equipment to meet the needs of different users of different business sizes.

Guranteed Quality and Service

Quality equipment achievements customer trust, and quality service let customers become partners. Every customer is very valuable and import to us, and your every need at DT food machine company will be listened to and paid 100% effort to meet.

The purpose of the production of cone machines is not only to make satisfactory cones, but to help each customer’s needs be met and his wishes be realized.

Donc, whether it is new customers or regular customers, we will listen to customers’ business plans and production difficulties, and give professional advice and solutions. En même temps, we have a professional after-sales team to track production, livraison, installation, customer use and business conditions and give the required support.

Plus de valeur pour le client

We will support you from ice cream market trend information sharing, selecting suitable solution for your ice cream business, supply the satisfactory cone machines and assist you with installation and recipe development. We make all efforts to you to help your food business startup and succeed.

Wafer Cone Machine Price

Cone machines price is varied because of machine type and model capacity range. Please contact our professional sales support to get standard price.

Cependant, for customized ice cream cone shape, logo design and sizes not in our previous production range, we will only need to add the customized cost on machine cost.

Talk to our team now to share more of your business plan and step forward on the journey of sweet and success.

What is the ingredient for making wafer cones?

Basic wafer cone ingredient suitable for wafer cone making machine is wheat flour, amidon, huile comestible, sel, et de l'eau, etc.. Nous vous fournirons le ratio de recette de base après la commande et vous pourrez ajouter vos ingrédients secrets pour avoir une saveur et un goût spéciaux..

Machines connexes

Ligne de production automatique de cornets de glace, automatic wafer cone maker, mélangeur à pâte, ice cream machine