Chips automatiques d'usine de chips de pomme de terre faisant la machine 100KG

Usine automatique de chips est une machine industrielle de fabrication de chips, transformer la pomme de terre en chips croustillantes et délicieuses.

Machine de fabrication de chips 100 kg par heure est efficace et permet d'économiser d'énormes coûts de production et de main-d'œuvre. Donc, il est plus adapté aux petites et moyennes usines de chips.

Application: Faire des chips, chips de patates douces, frites, chips longues de plantain, chips de banane, etc..

Matériel: Acier inoxydable de qualité alimentaire 304

Capacité: 100kg par heure, et capacité personnalisée disponible

Application automatique d’une usine de chips de pomme de terre

La machine de fabrication de chips automatique est populaire dans les petites et moyennes usines de chips et même dans les nouveaux démarreurs d'entreprise.. Et la machine de fabrication de chips transforme automatiquement les pommes de terre avec un faible taux d'eau et une teneur élevée en chips en chips croustillantes et délicieuses.. Dans la ligne automatique de fabrication de copeaux, la machine d'assaisonnement donne des saveurs spéciales aux chips et la machine d'emballage automatique de chips avec remplissage d'azote peut avoir une durée de conservation plus longue.

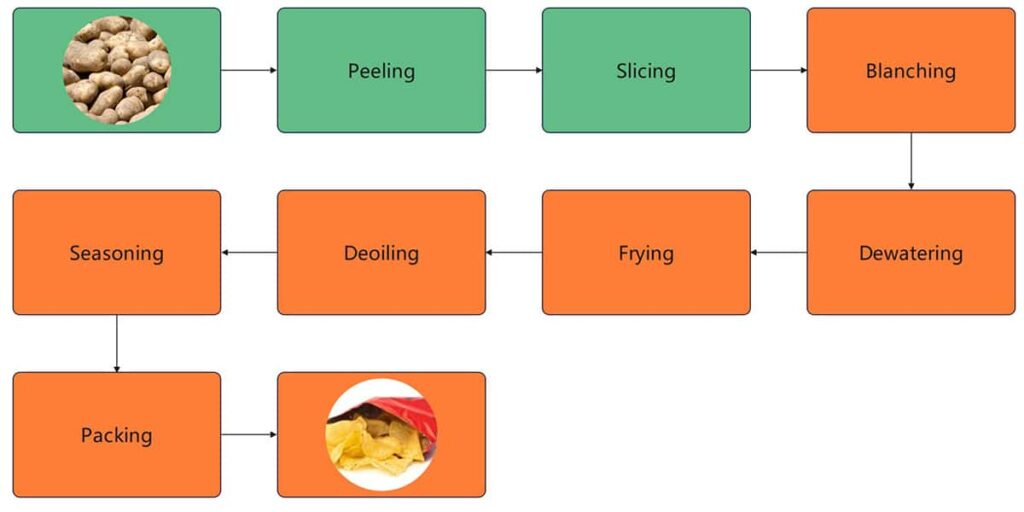

Normalement, l'usine automatique de chips doit couvrir le processus de production de lavage et d'épluchage des pommes de terre, tranchage, blanchiment, friture et emballage. Cependant, nous pouvons personnaliser la solution de production en fonction des caractéristiques du produit final, budget du client et capacité électrique de l'usine, etc.. Qui plus est, nous pouvons personnaliser la machine de fabrication de chips pour fabriquer des chips de banane, chips longues de plantain, etc..

Introduction automatique de machine de fabrication de puces

Description de la machine de fabrication de copeaux automatique

La machine automatique de fabrication de chips est conçue pour transformer les pommes de terre en délicieuses chips de pommes de terre.. Et il peut également être personnalisé pour faire des frites, chips de banane, etc. . Il existe des machines de fabrication de puces de différentes capacités pour répondre aux besoins de production des clients. En raison de sa grande efficacité, la machine à fabriquer des chips pour les entreprises réduit la main-d'œuvre et économise de l'énergie, donc, pour aider les investisseurs à obtenir de meilleurs rendements.

La machine à chips automatique comprend normalement une machine à éplucher les chips, machine de découpe de copeaux, machine à blanchir les pommes de terre, machine d'assèchement, friteuse de chips professionnelle, prix de la machine à déshuiler, mélangeur d'épices, et machine d'emballage.

En plus, ligne de production de croustilles de pommes de terre doit répondre à différentes demandes commerciales, donc, Nous avons conçu la ligne de production des croustilles semi-automatiques avec capacité 30 à 50 kg / h ou 50 à 100 kg / h. Mais nous avons également conçu une machine à chips entièrement automatique avec une capacité de 100 kg par heure jusqu'à 500 kg/h et une capacité supérieure peut être personnalisée..

La machine de fabrication de copeaux avec une production de 100 kg/h doit garantir une production entière avec moins de main-d'œuvre, plus efficace et plus facile à utiliser. Donc, nous mettons à jour le ligne de production de croustilles à petite échelle en ce qui concerne la machine à éplucher les pommes de terre automatique, machine à frire automatique à pot rond, et machine à doiler à décharge par le bas, et machine d'assaisonnement à tambour. Dans cette conception, Le processus de friture vers l'assaisonnement est le fonctionnement par lots mais moins d'intervention manuelle.

Spécifications automatiques de croustilles de pomme de terre

Méthode de chauffage: Chauffage électrique / Chauffage au gaz

Matériaux de machines: Qualité alimentaire 304 matériaux en acier inoxydable, meilleure qualité faite

Capacité: 100kg par heure une capacité plus élevée, personnalisable

Température de chauffage au mazout: 0℃ à 300 ℃ (Fahrenheit 32°F à 572.0 °F )

Ratio de pommes de terre et de croustilles: 3 à 3.5 : 1 Pour les références.

Recommandation: Temps de blanchiment:100 secondes à la température de l'eau: 80 à 100 ℃. Alors que, temps de fusion: 3 à 4 minutes, à la température de friture à l'huile: 170-180℃.

Exigence d'espace en usine: Nous pouvons personnaliser la ligne de production en fonction de la taille de l'usine et du plan d'étage.

Tableau d'écoulement des plantes de transformation des croustilles

Caractéristiques automatiques de machine à croustilles de pommes de terre

Chips Peeling Machine

La machine à épluche des copeaux est en acier inoxydable de qualité alimentaire 304. Les rouleaux en nylon de haute qualité décollent la peau de pomme de terre terminée. En plus, Les matériaux à rouleaux peuvent être personnalisés pour convenir à différentes racines comme les carottes, Cassava etc.

La machine à laver à la pomme de terre et la machine épluche élimine la pomme de terre sale pendant le processus de pelage. Et c'est simple à courir et à nettoyer la machine.

Et la machine de pelage a son propre système de départ et de dépistage qui permettent au travailleur à régler le temps de pelage pour différents matériaux.

Coupe-puces automatiques

Le prix de la machine Slicateur des puces convient pour couper la pomme de terre en tranches. Et aussi il peut utiliser pour couper les copeaux de banane, chips de patates douces, Anneaux d'oignon et autres racines.

L'épaisseur des copeaux peut être réglable et les tranches de copeaux sont uniformes sur cette machine à trancher des puces de pomme de terre.

En plus, Il y a quatre entrées pour nourrir les matières premières.

Prix de la machine à frire les pommes de terre

C'est frite avec de la trémie d'alimentation, et fonction de mélange, et fonction des matériaux de décharge. Donc, Il améliore considérablement l'efficacité et réduit la main-d'œuvre dans la machine de production des croustilles de pomme de terre.

Et le temps et la température de friture sont contrôlables et réglables en fonction des besoins.

Méthode de chauffage: Machine à frire de fracture et de chauffage à gaz électrique disponibles pour le client pour choisir le client.

Qui plus est, Il y a une mini machine à frire continue de 100 kg par heure peut être un bon remplacement si le client veut un processus de friture continu avec des croustilles à une extrémité et à l'extérieur de la fin.

Machine de déshuilage centrifuge

Croustilles de pommes de terre en la machine à utiliser un principe centrigigal pour éliminer l'huile sur les croustilles après la friture. Donc, les chips ne sont pas grasses, ont un meilleur goût et ont une longue durée de conservation.

Pendant le processus de rotation à grande vitesse, Il ne prend pas seulement le trop d'huile, mais aussi refroidir la température des copeaux.

Après le déoiling, Les puces sont décharges par le bas, qu'il y aura un elavator pour les envoyer à la prochaine machine d'assaisonnement.

Machine d'assaisonnement aux croustilles

La machine d'assaisonnement des croustilles est un processus d'assaisonnement continu, pour mélanger uniformément les copeaux de Potaot avec du sel et des épices.

L'avantage de cette machine d'assaisonnement est son faible taux de casse et convient à presque tous les types de chips., rondelles d'oignon, flocons de maïs, craquelins, poisson séché, haricots frits, etc..

Qui plus est, La trémie vaporisera uniformément les épices aux copeaux frits, La quantité d'épices est réglable en fonction du besoin.

Machine d'emballage des croustilles

Il s'agit d'une machine d'emballage de chips semi-automatique sans fonction de pesée. Il a une machine de remplissage, machine de fabrication et de scellage de sacs. Donc, le travailleur doit peser les chips avant de charger chaque lot dans des seaux sur cette machine d'emballage.

Il est doté d'une entrée de remplissage d'azote qui permet de réaliser des emballages remplis d'azote.. La machine est en coût écacimique. Cependant, pour les clients qui recherchent une solution d'emballage automatique, nous avons également la machine d'emballage automatique avec balance, fonction de remplissage, de fabrication et de scellage de sacs.

Paramètre de prix de la machine à chips automatique

Nous avons une machine automatique à chips d'une capacité de 100 kg par heure et plus.

| Modèle | DT-PC-30 | DT-PC-50 | DT-PC-100 |

| Entrée brute | 100 | 200 | 400 |

| Sortie des puces | 20-30KG | 30-50KG | 50-100KG |

| Tension | 380V / 220V | ||

Fabricant automatique de machines à chips de pommes de terre

Avantage

Usine de machines alimentaires à guichet unique

30 années R&Histoire D

Performances stables des machines

Livraison à temps

Garantie

12 Mois de garantie de qualité

Assistance technique à vie et service de pièces de rechange

Service

Support après-vente en opération, entretien.

Formation gratuite en ligne ou hors ligne en usine

Installation sur site dans l’usine du client

Conseils commerciaux globaux pour le nouveau planificateur d'affaires.

Services de livraison dans le pays de l'acheteur

Coût d'usine automatique de la machine à chips

Pour usine de chips, nous avons des chips semi-automatiques faisant le prix de la machine et croustilles entièrement automatiques rendant le prix de la machine accessible au client en fonction de la capacité réelle dont il a besoin, et exigence en matière d'automatisation et d'espace d'usine.

En plus, nous avons une équipe d'ingénieurs techniques professionnels et une équipe de développement de produits pour mettre à niveau notre ligne de production pour une plus grande efficacité, moins de production et meilleure satisfaction pour l'utilisateur. En plus, nous comprenons et répondons rapidement aux besoins des clients avec la solution adaptée à leur entreprise.

N'hésitez pas à contacter notre équipe dès maintenant pour une ligne de production de chips entièrement automatique.

Machines connexes

Petite usine de chips, Ligne de production de frites, ligne de production de chips de banane, ligne de friture de penauts. friteuse continue, friteuse à panier, friteuse automatique à casserole ronde, machine à frire continue.