Chaîne de production automatique de frites Machine de pommes de terre frites

Ligne de production automatique de frites is tailored to meet the growing demand for high-quality, consistent, and delicious French fries.

Potato french fries machine is applicable in food processing factories, which requires large quantities of uniform, high-quality French fries swiftly and efficiently.

Application: potato fries, crisps, and other similar snacks.

Matériel: Acier inoxydable de qualité alimentaire 304

Capacité: 100kg par heure, 200kg par heure, upto 300kg/h and customized capacity available

Automatic French Fries Production Line Application

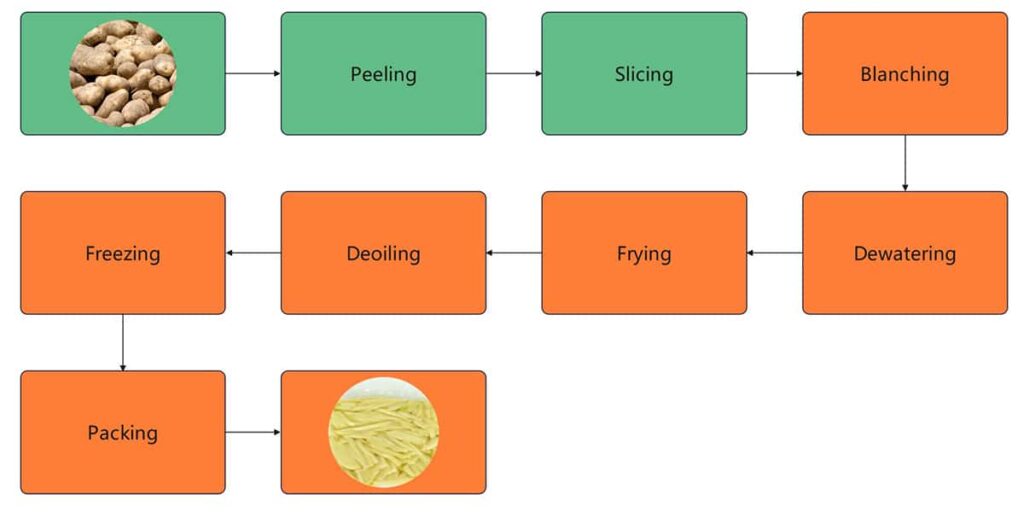

French fries production line uses the potatoes with low water rate and high starch content as raw materials, And through washing, peeling, tranchage, frying process, quick freezer and vacuum packing process, the french fries line turns the raw potato into delicious potato french fries.

Potato French fries production line offers a versatile solution to fast-food giant, a restaurant owner, or a food manufacturer. And the frozen french fries production line is flexible to make various chips such as banana chips, chips de patates douces, chips, frozen french fries etc.

Automatic Frozen French Fries Production Line Introduction

Automatic French Fries Production Line Description

Our automatic frozen French fries production line is a complete solution for producing large volumes of frozen and fried products such as potato fries, chips, and other similar snacks. And this frech fries processing plant is equipped with variety of machines that ensures high automation, simplicity in operation, and significant energy savings.

And this automatic french fries processing line starts with washing and peeling machine, followed by slicing machine, blanching machine for potatoes, round pot deep frying machine, bottom discharge type deoiling machine, quick freezer and finally packaging machine. Each machine is carefully designed to maximize output while maintaining the highest quality standards. En plus, food-grade materials and advanced technology ensures the french fries line meet all health and safety regulations.

Automatic French Fries Production Line Specification

Chauffage Method: Chauffage électrique / Chauffage au gaz

Matériaux de machines: Qualité alimentaire 304 matériaux en acier inoxydable, meilleure qualité faite

Capacité: 100kg per hour to 300kg per hour, personnalisable

Recommendation: Blanching time: 60 à 90 seconds at water temperature: 90 to 95℃. Alors que, frying time: 60s at oil frying temperature: 185℃. Freezing 30 à 50 minutes per batch -30~-35C;

Frech fries size: 7*7mm to 12912mm adjustable.

Emballer: Vaccum package, plastic pack etc.

Exigence d'espace en usine: Nous pouvons personnaliser la ligne de production en fonction de la taille de l'usine et du plan d'étage

French Fries Production Line Chart

French Fries Line Advantage

Efficacité accrue:

An automatic french fries production line can significantly increase your production capacity. With automated machinery handling tasks such as slicing, blanching, freezing, et emballage, you can produce a higher volume of frozen french fries in a shorter period. This can lead to increased sales and profitability for your business.Consistent Product Quality:

Automated french fries machinery ensures consistent product quality. The potato slicer machine cut potatoes to uniform thickness, blanching machine to cook potato stick with the perfect temperature, and potato frying machine with stable frying, and quick freezer to freeze french fries at a consistent rate. As as result, the ffinal frozen french fries that are uniform in size, forme, and texture, enhancing customer satisfaction and repeat purchases.Reduced Labor Costs:

Automatic frozen french fries production line can reduce the number of employees required to operate the machinery. As a resuitl, it can lower your labor costs. En plus, automated potato machinery can work continuously without needing breaks, further increasing your productivity.Sécurité améliorée:

Automated french fries machinery reduces the risk of workplace injuries. With fewer employees required to handle machinery and materials, the likelihood of accidents is significantly decreased. This can lead to lower insurance costs and fewer workplace injuries, creating a safer and more productive work environment.

French Fries Line Features

Potato Washing and Peeling Machine Price

Washing and peeling machine is made of food grade stainless steel 304. Which ensure durable usage and food safty.

The high quality nylon rollers peels the potato skin completes. En plus, the roller materials can be customized to be suitable on different roots like carrots, cassava etc.

Potato washer and peeler machine removes potato dirty during peeling process. And it is simple to run and clean the machine.

And potato washing peeling machine has its own start on and off control system which allow the worker to adjust peeling time for different materials.

Potato Fries Cutter Machine

Automatic french fry cutter is suitable for cutting potato into slices from 7mm to 12mm. And potato french fry cutter can use for cutting banana chips, chips de patates douces, onion rings and other roots.

By this electric french fry cutter, the potato stick size is uniform and less waste.

French Fries Frying Machine

This is round pot batch fryer with feeding hopper, and mixing function, and discharge materials function. Donc, it greatly improves the efficiency and reduces labor in potato chips production machine.

And the frying time and temperature is controllable and adjustable based on needs.

Méthode de chauffage: Electric deep fryer and gas heating frying machine available for customer to choose.

Machine de déshuilage centrifuge

French fries deoiling machine use centrigugal principle to remove oil on french fries after frying. Donc, the fried french fries is not oily and better taste and have long shelf life.

During the high speed spinning process, it does not only take away the too much oil but also cool down the french fries temperature as well.

After deoiling, the potato sticks are discharged from bottom, which there will be an elavator to send them to next stage.

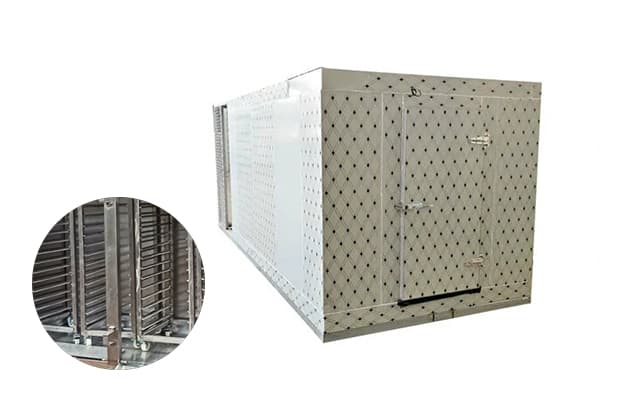

French Fries Freezer

The french fries freezer is to freeze the french fries in -30~-35℃ temperature in about 30 à 50 minutes, until central temperature-18℃.

This is batch type freezer for small and medium capacity french fries plant.

Packing Machine for Chips

We have single chamber vacuum packing machine and double chamber vacuum sealer according to package size and capacity requirement.

It can be used for do vacuum package for french fries, ail, fresh potato slices, carottes etc..

Frozen French Fries Production Line Parameter

As professional french fries production line manufacturers, we customize our frozen potato production line to meet business size. Here is our automatic frozen french fries production line data and we are able to customize fully automatic potato french fries machine production line.

| Modèle | DT-FF-100 | DT-FF-200 | DT-FF-200 |

| Raw Input | 200KG | 400KG | 600KG |

| Chips Output | 100KG | 200KG | 300KG |

| Tension | 380V / 220V | ||

French Fries Production Line Manufacturers

Avantage

Usine de machines alimentaires à guichet unique

30 années R&Histoire D

Performances stables des machines

Livraison à temps

Garantie

12 Mois de garantie de qualité

Assistance technique à vie et service de pièces de rechange

Service

Support après-vente en opération, entretien.

Formation gratuite en ligne ou hors ligne en usine

Installation sur site dans l’usine du client

Conseils commerciaux globaux pour le nouveau planificateur d'affaires.

Services de livraison dans le pays de l'acheteur

French Fries Production Line for Sale

The cost of an automatic frozen french fries production line can vary depending on the size and complexity of the machinery. It is important to set a budget before you begin your search for the perfect production line. Consider your production needs, labor costs, and potential profit gains to determine the best investment for your business.

We offer competitive pricing for our automatic frozen French fries production line, avec des options pour personnaliser les machines selon vos besoins spécifiques. Contactez-nous dès aujourd'hui pour un devis détaillé et pour en savoir plus sur nos produits et services.

Machines connexes

Fully automatic french fries production line, mini usine de chips, ligne de production de chips de banane, ligne de friture de penauts. friteuse continue, friteuse à panier, friteuse automatique à casserole ronde, machine à frire continue.