Spaghetti Machine Automatic Spaghetti Production Línea 2000 kg/h

Spaghetti Machine is industrial production solution on making spaghetti in efficient and hygiene way, in order to meet growing demand for high-quality, consistently produced spaghetti and pasta products.

Solicitud: various types of spaghetti

Capacidad: 100kg por hora, 200kg/hora, 500kg/hora, 1000kg/hora, 2000kg/hora, y capacidad personalizada

Control system: Totalmente automático, sistema de control plc

Spaghetti Machine Maker Application

Spaghetti, being an iconic Italian pasta variety, has gained widespread popularity across the world due to its versatility, nutritional value, and ability to be paired with a multitude of sauces and ingredients. Y spaghetti market has been growing steadily over the years, driven by increasing consumer demand for convenient, nutritious, and delicious food options. And our línea de producción de macarrones and cut pasta production line enable investors and food plant with efficient, hygiene and high capacity production solution.

Spaghetti pasta meker is ideal for a wide range of food production environments, including manufacturing plants, food & beverage factories, and even medium size pasta plants. And spaghetti machine is capable of producing a variety of pasta shapes and sizes, making it a versatile addition to any food production setup.

Spaghetti Machine Maker Introduction

Spaghetti Processing Machine Description

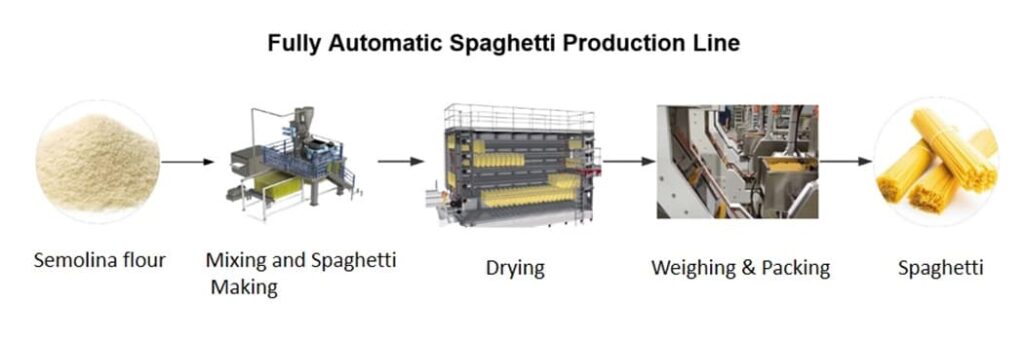

Spaghetti maker machine is fully automatic spaghetti processing line which increases efficiency, enhances production quality at less labor cost. And our automatic spaghett processing line is complete system includes raw materials storage and pumping system, powder feeding and raw materials mixing system, spaghett noodle making system, noodle drying system, spaghetti cutting machine, and noodle weighing and packing system.

Designed with automazition and previous control, the automatic spaghetti production line is able handle large volumes of production with minimal human intervention. And it combines conveyor systems, and intelligent control mechanisms to deliver a seamless production process.

We have spaghett making machine models with output 100kg an hour to 2000kg an hour. In order to meet different size of noodle plant.

Professional Pasta Making Machine Specification

Continuous Drying System: PLC Control to achieve accuracy in temperature and humidity with less labor.

Capacidad: 100kg/hora, 200kg/hora, 300kg/hora, 500kg/hora, 1000kg/hora, 2000kg/h y capacidad personalizada

Voltaje: 380V 50HZ 3ph and customized voltage

Spaghett type: Spaghetti, Linquine, Spaghetti guadri with various sizes

Materiales: Stainless steel material

Tipo de paquete: Plastic bag, boxes, as per demand.

Automatic Spaghetti Maker Flow Chart

Automatic Spaghetti Maker Features

- Alta automatización: The automatic spaghetti paste noodle production line is fully automated, Reducir la necesidad de mano de obra manual y minimizar el error humano.

- Precision and Consistency: The spaghetti paste machine produces spaghetti of consistent quality and size, ensuring a uniform product

- Versatilidad: Spaghetti extruding machine can be adapted to produce different pasta shapes and sizes by changing the dies.

- Eficiencia energética: Whole automatic spaghetti processing line is designed to be energy-efficient, reducing operational costs.

Best Spaghetti Maker Parameter

| No. | Machine | Cantidad | Voltaje |

| 1 | Powder Silo | 1Colocar | 380V 50HZ 3F, y voltaje personalizado |

| 2 | Powder feeding system | 1Colocar | 380V 50HZ 3F, y voltaje personalizado |

| 3 | DT-2000 vacuum mixer | 1Colocar | 380V 50HZ 3F, y voltaje personalizado |

| 4 | DT-2000 vacuum extruder | 1Colocar | 380V 50HZ 3F, y voltaje personalizado |

| 5 | Water cooling device | 1Colocar | 380V 50HZ 3F, y voltaje personalizado |

| 6 | DT-2000 long cutting machine | 1Colocar | 380V 50HZ 3F, y voltaje personalizado |

| 7 | DT-2000 pre-dryer | 1Colocar | 380V 50HZ 3F, y voltaje personalizado |

| 8 | DT-2000 automatic drying line | 1Colocar | 380V 50HZ 3F, y voltaje personalizado |

| 9 | DT-2000 Cooling system | 1Colocar | 380V 50HZ 3F, y voltaje personalizado |

| 10 | DT-2000 Finished product cutting machine | 1Colocar | 380V 50HZ 3F, y voltaje personalizado |

| 11 | DT-2000 storage warehouse | 1Colocar | 380V 50HZ 3F, y voltaje personalizado |

| 12 | DT-520 automatic package | 1Colocar | 380V 50HZ 3F, y voltaje personalizado |

Fully Automatic Pasta Maker Manufacturer

Ventaja

Fábrica integral de maquinaria alimentaria.

30 años R&D historia

Rendimiento estable de la maquinaria

Entrega a tiempo

Garantizar

12 Meses de Garantía de Calidad

Soporte técnico de por vida y servicio de repuestos.

Servicio

Soporte postventa en funcionamiento, mantenimiento.

Formación gratuita on line o off line en fábrica

Instalación in situ en la fábrica del cliente.

Consejos comerciales generales para planificadores de nuevos negocios..

Servicios de entrega al país del comprador.

Diseño de fideos de fideos, receta que proporciona, y Solución de condimento y embalaje que proporciona.

Spaghetti Machine price

Contamos con un equipo de ingenieros técnicos profesionales y un equipo de desarrollo de productos para actualizar nuestra línea de producción y lograr una mayor eficiencia., Menos producción y mejor satisfacción para el usuario.. Además, Entendemos y respondemos rápidamente a las necesidades del cliente con la solución adecuada para su negocio..

You are most welcomed to contact our team now for spaghetti making machine price.

Máquinas relacionadas

línea de producción de fideos instantáneos a pequeña escala, creador de fideos, línea de producción de fideos de palo, línea de producción de pasta macarrones.