Máquina automática de papas fritas congeladas Planta de procesamiento de papas fritas

Francés línea de producción de papas fritas es una solución de producción automática y avanzada para procesar patatas y convertirlas en patatas fritas..

Planta automática de procesamiento de patatas fritas. Contiene máquina para lavar y pelar patatas., maquina cortadora de papas fritas, máquina blanqueadora, maquina deshidratadora, freidora de papas fritas, máquina desengrasante, máquina de enfriamiento, congelador rápido, Máquina envasadora automática y sus equipos auxiliares..

Aplicado a: Papas fritas, chips de batata, chips de plátano largos, papas fritas, papas fritas frescas, papas fritas congeladas, chips de plátano, etc..

Capacidad: 50-100kg/hora, 200-250kg/hora, 350-400kg/hora, 500kg/hora, 1000kg/hora, 1500kg/hora, 2000kg/h y capacidad personalizada.

Aplicación de la línea de producción de papas fritas congeladas

Máquina para hacer patatas fritas congeladas es una solución avanzada para los fabricantes de patatas fritas congeladas. No hay agua, es una línea de producción automática de máquinas de papas fritas para fábricas de papas fritas más grandes., o línea de producción de papas fritas congeladas a pequeña escala para fábricas de tamaño mediano o nueva fábrica de papas fritas. Nuestras plantas procesadoras de patatas permiten a los inversores obtener buenos rendimientos al reducir en gran medida la mano de obra., mejorar la calidad del producto, proporcionando productividad y participación de mercado.

La máquina para fabricar patatas fritas congeladas también es popular entre los fabricantes de snacks que desean que la línea fabrique varias patatas fritas., como patatas fritas, chips de plátano, chips de batata, etc.. Y por la estacionalidad de las materias primas., Necesitan una línea de producción para la producción fuera de temporada para producir otros productos..

Introducción a la línea de producción de patatas congeladas

Descripción de la línea de producción de papas fritas congeladas

La máquina comercial de papas fritas es una línea de producción completa que cubre máquinas lavadoras y peladoras de materias primas., máquina blanqueadora, cortador de patatas, freidora de papas fritas, congelador rápido, máquina automática de pesaje y ensacado.

Y personalizamos la planta procesadora de papa para satisfacer diferentes tamaños de empresas.. Por lo tanto, Contamos con una línea de producción de papas fritas semiautomática con una capacidad de 50 kg por hora, pero también una línea de producción de papas fritas a pequeña escala con una producción de 100 kg por hora., y línea de producción de papas fritas congeladas totalmente automática de hasta 2000 kg por hora. Además, Personalizamos la máquina para hacer patatas fritas con la capacidad que necesita el cliente..

Especificación de la línea de producción de papas fritas para la venta

Método de calentamiento: Calefacción eléctrica / Calefacción de gas

Materiales de la máquina: Grado alimenticio 304 materiales de acero inoxidable, mejor calidad hecha

Temperatura de calentamiento del aceite: 0℃ a 300 ℃ (Fahrenheit 32 °F a 572.0 °F)

Capacidad: 50KG/H a 2000 KG/H (Se puede personalizar una mayor capacidad.)

Requisito de espacio de fábrica: Podemos personalizar la línea de producción según el tamaño de la fábrica y el plano de planta..

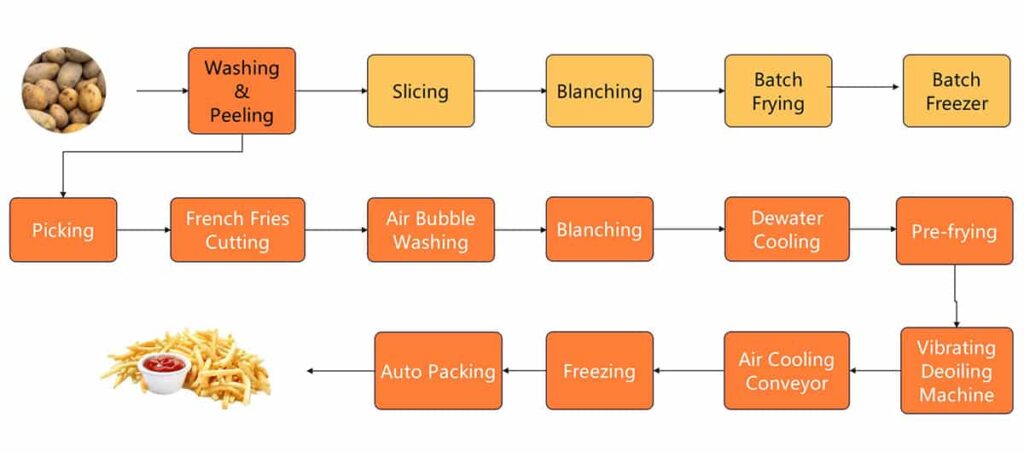

Diagrama de flujo de la máquina de papas fritas completamente automática

Incluye una línea de producción de papas fritas a pequeña escala, flujo de procesamiento de línea de producción de papas fritas semiautomática y completamente automática..

Características de la máquina de papas fritas

Peladora de patatas

Esta es una lavadora y peladora continua. lavado, pelar y descargar.

Porque los cepillos irregulares y corrugados se componen de un cepillo de cerdas duras y un cepillo de esmeril que permiten pelar las patatas por completo..

Además, La máquina peladora tipo espiral empuja la papa hacia adelante y la descarga desde el otro extremo para recoger las cintas transportadoras antes del proceso de corte..

Además, Es adecuado para lavar y pelar patatas., batata, mandioca, jengibre, cebolla, zanahorias, etc..

Máquina cortadora de patatas fritas eléctrica

La máquina cortadora de patatas fritas es un cortador comercial de patatas fritas con alto rendimiento.. Y palitos franceses de tamaño 7*7mm, 8*8milímetros, 10*10milímetros, y hecho a medida se puede cambiar ajustando la hoja.

La máquina cortadora de patatas fritas también es adecuada para otros tubérculos, como zanahorias, mandioca, etc..

El producto final es suave., uniforme y libre de roturas.

Blanquear patatas antes de freírlas

Esta es una máquina blanqueadora para proteger el color de las barritas francesas y mantener el sabor del producto..

El tiempo de ramificación de las patatas fritas es aproximadamente 5 a 15 minutos a temperatura de agua caliente 70 ℃ (158.0 °F). Y la correa de malla de acero inoxidable tiene regulación de velocidad de conversión de frecuencia., por lo que el tiempo y la velocidad de escaldado son ajustables.

Hay máquinas de ramificación continua con calefacción de gas y máquinas de ramificación continua con calefacción eléctrica para que el cliente elija.

Máquina deshidratadora de patatas

La máquina de enfriamiento por aire elimina el agua y enfría la temperatura de los palitos de papa ramificados antes de freírlos. Acorta el tiempo de fritura y garantiza el sabor de calidad de las patatas fritas..

Y para tener un mejor efecto, Es necesario utilizar una máquina desengrasante vibratoria antes de secar al aire y deshidratar la cinta transportadora..

freidora de papas fritas

Para planta de papas fritas a pequeña escala, La freidora tipo cesta o la freidora de olla redonda es la opción ideal para capacidades inferiores a 200 kg por hora..

Sin embargo, para planta de producción de patatas fritas totalmente automática, la freidora continua Es la mejor opción para mantener el tiempo de fritura continuo trabajando con mayor capacidad y menos mano de obra.. La mejor máquina para hacer patatas fritas es de acero inoxidable y su tiempo de fritura es ajustable y la temperatura del aceite es ajustable..

Además, También podemos personalizar la freidora para automatizar el proceso de recarga de aceite., reciclaje de aceite, Sistema de filtrado de aceite y autolimpieza.. Esto mejorará enormemente la eficiencia de la producción., prolongar el uso de aceite y papas fritas de mejor calidad.

Máquina desengrasante

La máquina desaceitadora vibratoria es necesaria para eliminar el aceite de la superficie de las patatas fritas después de freírlas..

Porque, Los palitos franceses fritos de la línea de fritura normalmente contienen algunos aceites que hacen que el producto se vuelva aceitoso y pueden contaminar el piso de producción.. Por lo tanto, La máquina vibratoria con placas receptoras de aceite es buena para desengrasar el aceite de la superficie de las virutas y mantener limpio el sitio de producción..

¿Qué es más?, durante el proceso de vibración, Los chips avanzan y se extienden incluso al siguiente proceso..

Máquina de enfriamiento

Se instala un transportador de enfriamiento con ventiladores que soplan viento hacia las papas fritas. Por lo tanto, la temperatura de la superficie cae bruscamente debido al fuerte viento natural.. Este es un proceso importante antes del proceso de congelación rápida..

Y la placa receptora de aceite debajo del transportador de enfriamiento es opcional para recibir el aceite que cae de las papas fritas..

Congeladores de patatas fritas Congeladores tipo túnel Congeladores IQF

El congelador rápido de papas fritas es aplicable para congelar grandes cantidades de papas fritas en cortos períodos de tiempo sin que se formen grumos ni que el producto se pegue..

Temperatura central del material a alimentar.:<20 do

Temperatura de descarga: -18℃

tiempo de congelación: 15 min a 45 minutos.

Máquina automática de embalaje con pesaje, Llenado y fabricación de bolsas

Para empacar papas fritas congeladas en una bolsa de plástico automáticamente, La máquina automática de llenado y sellado de bolsas es la opción ideal.. Incluye ascensor, pesadora multicabezal, forma plana, Dispositivos para hacer bolsas con función de impresión de fecha., y un transportador de producto final.

¿Qué es más?, La máquina empacadora de chips tiene la ventaja de una alta eficiencia., pesaje preciso, y trabajando continuamente con la línea de procesamiento de papas fritas.

Parámetro de la línea de procesamiento de papas fritas

Lista de máquinas de papas fritas congeladas como se muestra a continuación solo como referencia. Y podemos personalizar la línea de procesamiento de papas fritas según el diseño de la fábrica del cliente., Voltaje, variedades de productos finales, tipo de embalaje, etc..

| No. | Nombre de la máquina | Cantidad | Unidad | Tasa de voltaje |

| 1 | Ascensor | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 2 | Lavadora y peladora de patatas | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 3 | Seleccionar cinta transportadora | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 4 | cortador de patatas | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 5 | Elevador de pulverización del cubo | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 6 | Máquina recolectora de patatas fritas no calificada | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 7 | máquina de enjuague | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 8 | máquina blanqueadora | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 9 | Deshidratador por vibración | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 10 | Secador enfriado por aire | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 11 | Ascensor | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 12 | freidora continua | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 13 | Máquina desengrasante vibratoria | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 14 | Secador enfriado por aire | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 15 | Máquina esparcidora de papas fritas | Colocar | 380V 50HZ 3ph Se puede personalizar | |

| 16 | Congelador | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

| 17 | Máquina de embalaje | 1 | Colocar | 380V 50HZ 3ph Se puede personalizar |

Fábrica de máquinas para hacer patatas fritas

Ventaja

Fábrica integral de maquinaria alimentaria.

30 años R&D historia

Rendimiento estable de la maquinaria

Entrega a tiempo

Garantizar

12 Meses de Garantía de Calidad

Soporte técnico de por vida y servicio de repuestos.

Servicio

Soporte postventa en funcionamiento, mantenimiento.

Formación gratuita on line o off line en fábrica

Instalación in situ en la fábrica del cliente.

Consejos comerciales generales para planificadores de nuevos negocios..

Servicios de entrega al país del comprador.

Precio de la máquina de papas fritas

Contamos con un equipo de ingenieros técnicos profesionales y un equipo de desarrollo de productos para actualizar nuestra línea de producción y lograr una mayor eficiencia., Menos producción y mejor satisfacción para el usuario.. Además, Entendemos y respondemos rápidamente a las necesidades del cliente con la solución adecuada para su negocio..

Le invitamos a ponerse en contacto con nuestro equipo ahora para conocer el costo de la planta de fabricación de papas fritas..

¿Cuál es la mejor papa utilizada para la línea de papas fritas congeladas??

Shepody es una variedad de papa de piel blanca que se originó en New Brunswick., Canadá y se utiliza para hervir., hornada, y fritura francesa. su dmuy importante 19-21%, bajo contenido de azúcar reductor≤ 0.4% , especialmente indicado para procesos de fritura.

¿Qué es más?, Las patatas fritas en los restaurantes de comida rápida y las patatas fritas en los supermercados se producen en masa en fábricas.. el bien formado, Shepody de ojos claros es fácil de pelar durante la producción., y las patatas fritas y patatas fritas resultantes rara vez muestran agujeros y cicatrices..

Por lo tanto, Shepody es el tipo de papa ideal para la producción de papas fritas congeladas..

Máquinas relacionadas

Máquinas de patatas fritas, línea de producción de chips de plátano, línea para freír cacahuates. freidora continua, Línea de producción de patatas fritas a pequeña escala.