Waffeltüten-Herstellungsmaschine Mini-Eistütenmaschine DT-4

Waferkegel Maschine DT-4 ist eine Mini -Eiscreme -Maschine, mit 4 Backformen. Und seine Ausgabe is 100 Teile zu 120 Stück pro Stunde. Es ist ein professioneller Waferkegel Amker für die Herstellung von Waferkegeln aus verschiedenen Eiscreme -Kegelformen und -größen. Wie Hornformkegel, Fackelkegel, Schüsselkegelkegel, Twin Head Wafer -Kegel,Waferbox, Mais Waferkegel usw..

Kapazität: 100 bis 120pcs/h

Heizquelle: Elektrische Heizung, 220V 50 Hz Single und Customized Spannung

Materialien: Außenbedeckung Edelstahl

Eisporte Waferkegelmaschine Anwendung

Die Mini -Eiscreme -Kegelmaschine ist eine kompakte und effiziente Lösung für Unternehmen, die ihr Snackangebot verbessern möchten. Diese kleine Waferkegelmaschine ist nicht nur für den kommerziellen Gebrauch in Eisdielen geeignet, Bäckereien, und Snackfabriken, bietet aber auch eine vielseitige Plattform für verschiedene kulinarische Anwendungen.

Was ist ein Waferkegel?

Eiswaferkegel ist ein Lichtkegel, der leicht ist, goldbraun, mit einer knusprigen Textur neutralgeschmack. Es erhält den niedrigsten Zuckergehalt. Und sie werden in Kegelformform gebacken, Keine Chance, dass Eis durch den Boden austritt.

Diese Waferkegel eignen sich perfekt zum Servieren von Eiscreme, Eiscreme, Sorbet, oder ein anderes gefrorenes Dessert.

Eiswaferhersteller DT-4

Mini Ice Cream Cone Maker DT-4 ist ideale Wahl für den Hausgebrauch und die Nutzung der Eisdiele, Hochwertige Waferkegel machen. Der Waferkegelhersteller DT-4 hat 4 Köpfe Backformen. Und seine Kapazität ist 100 Stücke zu 120 Stück pro Stunde. Außerdem, Die Waferkegelmaschine DT-4 kann auch verschiedene Formen und Größen von Zapfen produzieren, Verpflegung der vielfältigen Präferenzen der Verbraucher. Wie Hornformkegel, Fackelkegel, Schüsselkegelkegel, Twin Head Wafer -Kegel,Waferbox, Mais Waferkegel usw..

Eiswaferkegelmaschine Spezifikation

Name: Eiswafermaschine

Modell: WC-DT-4

Kapazität: 100 bis 120pcs/h

Preis: Bester Preis, direkte Angebot von Fabrik mit höchster Qualität

Heizquelle: Elektrische Heizung

Spannungsrate: Standard 220 V 50 Hz Einphase. Freundliche Notiz: Spannungsänderungskosten werden als Kundenbedarf separat berechnet.

Materialien: Außenabdeckung der Maschine ist Edelstahlmaterial

Anpassung: Das Wafer Cone MachineWC-DT-4 wird nach Kegelformen und -größen angepasst. Jedoch, Jeder Satz von Kegelbackmaschine ist nur für eine Größe und eine Form von Zapfen angepasst

Icecream Wafer Maker zum Verkaufsparameter

Daten zum Eisporte -Wafer -Hersteller aus Edelstahl

| Name | Waferkegelmaschine Mini -Eiskegelmaschine | |||||

| Modell | DT-4 / DT-WC4 | DT-WC10 | DT-WC24C | DT-WC32C | DT-WC40 | DT-WC60 |

| Anzahl der Backform | 4 | 10 | 24 | 24 | 40 | 60 |

| Kapazität | 100 bis 120pcs/h | 250 bis 300pcs/h | 600 Zu 800 Stk/h | 600 Zu 800 Stk/h | 1200 Zu 1400 Stk/h | 2400 Zu 3000 Stk/h |

| Leistung | 3.6kW | 5kW | 12kW | 15kW | 18kW | 12kW |

| Stromspannung | 380V 50 Hz drei Phasen | |||||

| Dimension in mm | 530× 430 × 700 | 760× 600 × 1050 | 730× 800 × 1370 | 880× 880 × 1380 | 1080× 890 × 1465 | 1120× 11080 × 1550 |

| Nettogewicht | 80KG | 200KG | 350KG | 450KG | 660KG | 1050KG |

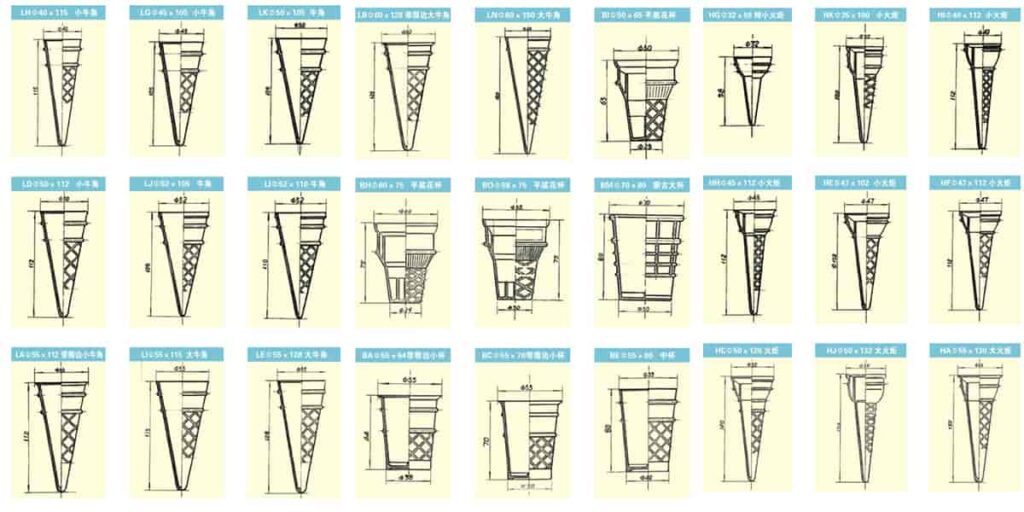

Zeichnung der Eiskegelzeichnung zur Auswahl zur Verfügung

Waferkegelmaschine Merkmal

Einfache Installation und einfacher Betrieb mit weniger Wartungskosten

In den meisten Fällen, Wir packen die ganze Maschine in ein Paket ein. daher, So installieren Sie die elektrische Heizeismaschine, Sie benötigen eine Person mit elektrischem Hintergrund oder professionellem Elektroingenieur, um die Maschine mit der Hauptleistung Ihres Workshops oder Ihrer Küche zu verbinden und die Maschine zu verwenden.

Der Arbeiter muss Teigpaste zum manuellen Backen von Schimmel füttern, Ziehen Sie den Griff auf der Maschine ab, um die Backformen zu schließen. Nach dem Backzeit ist vorbei, Der Arbeiter muss die Backformen hochziehen, damit die Zapfen die Entladung vom Boden aus dem Boden ermöglichen und die nächste Stapelproduktion beginnen können. Die Operation ist einfach.

Der Benutzer wird dem Wartungshandbuch folgen, um sich nach der täglichen Produktion um die Maschine zu kümmern. Jedoch, Der einfache Ersatzteil sind Heizungen, die sich möglicherweise nach der Verwendung von fast einem Jahr ändern müssen. Normalerweise liefern wir zusätzliche Ersatzheizung mit Lieferung der Waferkegelmaschine und empfehlen Kunden, mehr mit Maschine als Ersatzteile zu bestellen.

Trennende Backregelung an unteren Backformen und oberen Formen

Es gibt eine separate Heizsteuerung für den gesamten Satz der oberen Backformen und die anderen Set von Down -Backformen. Der Benutzer muss die Backtemperatur basierend auf unserem Fabrikversuchstest am besten Ergebnis einstellen, Sie können sich entsprechend ihrem Bedarf anpassen. Es ist einfach, die Daten manuell einzustellen.

Anpassungsdienst

Waferkegel haben verschiedene Formen , Größe und Logo -Design aus der Eiscremefabrik. daher, DT -Waferkegel -Backmaschine muss die Backformen und ihre Fähigkeit anpassen, die Nachfrage von verschiedenen Kunden zu befriedigen.

Freundliche Notiz, Für unseren Benutzer ist es wichtig, mit unserem Team zu sprechen, Teilen des Endproduktdesigns, Größe und Form, um eine endgültige Lösung zu erhalten.

Außerdem, Die Industriespannungsrate ist in jedem Länder nicht alle gleichen. Also, Wir können die Kegel -Backmaschine in der Fabrik vor der Lieferung an den Kunden anpassen.

Benutzerfreundlich

Der Kegeleisemacher ist dem Bediener sehr freundlich, insbesondere Benutzer ohne technische und männliche Betriebserfahrung. Der Bediener kann normalerweise mehr als eine Maschine gleichzeitig betreiben, Schließen Sie die Formen zum Backen und öffnen Sie die Formen, um fertig gebackene Zapfen abzuleiten.

Anzeigen des DT Mini -Eiscreme -Maschinenlieferants

Über 30 Herstellung und Entwicklung des Jahres Wafer -Kegelmaschinenmaschinen

Jahrzehnte Produktion und Verbesserung der Kegelgeräte, Damit unsere Benutzer eine bessere Erfahrung haben. Aus der anfänglichen semi-automatischen Waferkegelmaschine, Es wurde auf die SPS -kontrollierte automatische Waferkegelmaschine verbessert, und schließlich zur automatischen Tunnel -Wafer -Kegelmaschine, die von großen Eiscremefabriken verwendet wird. Wir waren schon immer daran interessiert, unsere Ausrüstung anzupassen, um den Anforderungen verschiedener Nutzer verschiedener Geschäftsgrößen zu erfüllen.

Qualität und Service Guranteed

Qualitätsgeräte Leistungen Kundenvertrauen, und qualitativ hochwertiger Service lassen Kunden Partner werden. Jeder Kunde ist sehr wertvoll und importiert für uns, und jeder Bedarf bei DT Food Machine Company wird angehört und bezahlt 100% Bemühungen zu treffen.

Der Zweck der Produktion von Kegelmaschinen besteht nicht nur darin, zufriedenstellende Zapfen zu machen, aber die Bedürfnisse jedes Kunden erfüllt und seine Wünsche realisiert werden.

daher, Ob neue Kunden oder Stammkunden, Wir werden Kunden zuhören’ Geschäftspläne und Produktionsschwierigkeiten, und professionelle Beratung und Lösungen geben. Gleichzeitig, Wir haben ein professionelles After-Sales-Team, um die Produktion zu verfolgen, Lieferung, Installation, Kundennutzung und Geschäftsbedingungen und den erforderlichen Support geben.

Mehr Wert für den Kunden

Wir werden Sie vom Eis Trendinformationen der Eismarkt unterstützen, Auswählen einer geeigneten Lösung für Ihr Eisgeschäft, Liefern Sie die zufriedenstellenden Kegelmaschinen und unterstützen Sie die Installation und Rezeptentwicklung. Wir bemühen uns, Ihrem Lebensmittelgeschäftsstartup zu helfen und erfolgreich zu sein.

Preis kleiner Waferkegelmaschine

Der Preis der Kegelmaschinen wird aufgrund des Maschinen- und Modellkapazitätsbereichs variiert. Bitte wenden Sie sich an unseren professionellen Verkaufsunterstützung, um den Standardpreis zu erhalten.

Jedoch, Für maßgeschneiderte Eiskegelform, Logo -Design und Größen nicht in unserer vorherigen Produktionsbereich, Wir müssen nur die individuellen Kosten für Maschinenkosten hinzufügen.

Sprechen Sie jetzt mit unserem Team, um mehr von Ihrem Geschäftsplan zu teilen und auf die Reise von Sweet and Success voranzukommen.

Was ist der Zutat für die Herstellung von Waferzapfen?

Grundlegende Waferkegelzutat für Waferkegelmaschine ist Weizenmehl, Stärke, Essbaröl, Salz, und Wasser usw.. Wir bieten Ihnen das grundlegende Rezeptverhältnis nach der Bestellung und Sie können Ihre geheimen Zutaten hinzufügen, um speziellen Geschmack und Geschmack zu haben.

Wie man Waferkegel macht ?

Elektrische Eiswaferkegelmaschine ist eine ideale Backmaschine für die Herstellung von Waferkegeln. Und hier ist der grundlegende Prozess der Verwendung eines Waferkegelherstellers. Legen Sie die Maschine auf flachem Boden. Schließen Sie es mit der Hauptkraft der Werksmast an.

- Befolgen Sie das manuelle Buch, um jeden Teil der Maschine zu überprüfen, um sicherzustellen.

- Reinigen und vorheizen Sie die Maschine. Bitte bürsten Sie Fettöl an allen Seiten von Backformen zum ersten Mal verwendet, um die Maschine zu vermeiden, um Pastestäbe für Backformen zu vermeiden. Und bitte entfernen. Freundliche Erinnerung,Es darf nicht harte oder scharfe Messer verwenden, um die Backformen zu reinigen, Um Schäden an Backformen zu vermeiden.

- Backmaschine einschalten. (Backzeit und Backtemperatur sind vor der Entbindung voreingestellt, Es ist jedoch anhand des Produktbedarfs auf der Benutzerseite einstellbar.

- Nach der Produktion, Stecken Sie die Maschine ab, und Strom abschneiden. Reinigen Backmaschine gemäß dem Buch des Benutzers.

Verwandte Maschinen

Automatische Eiscremeproduktionslinie, Automatischer Waferkegelmacher, Teigmischer, Eismaschine DT-24C