Introduction

In the fast-paced modern world, instant noodles have become a staple food for millions, offering convenience, affordability, and taste. Behind this global phenomenon lies a sophisticated manufacturing ecosystem centered around theinstant noodles production line. This article delves into the critical aspects of instant noodles production, including key manufacturers, pricing dynamics, and cutting-edge solutions. Whether you’re a startup looking to enter the market or an established player seeking upgrades, understanding the components and features of a high-efficiency production line is vital. Finally, we’ll highlight whyDT-Lebensmittelmaschine stands out as a leading provider of innovative and reliable solutions.

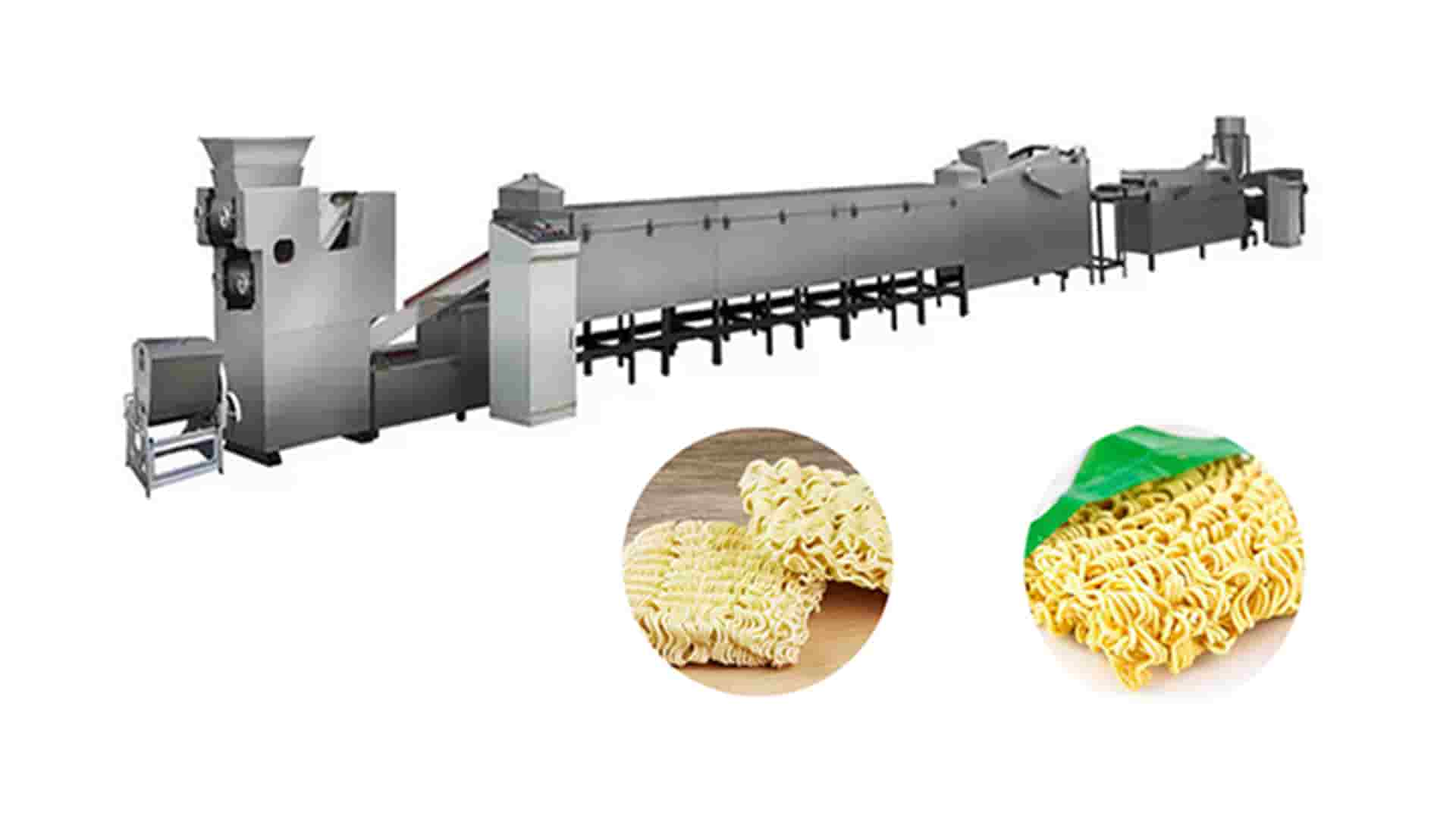

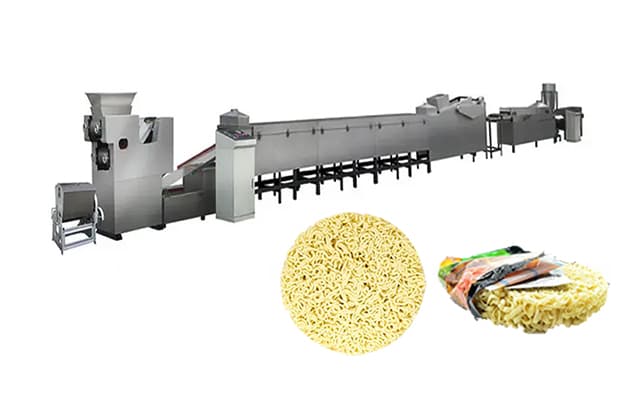

I. The Components of an Instant Noodles Production Line

A state-of-the-art instant noodles production line integrates multiple stages, from raw material processing to final packaging. Here’s a breakdown of its core components:

1.Raw Material Preparation System

- Flour Mixing & Blending: Automated mixers ensure precise ratios of wheat flour, Stärke, and additives.

- Water Treatment: Advanced filtration and purification systems guarantee water quality for dough consistency.

2.Dough Processing Unit

- High-Speed Mixers: Dual-axis mixers with variable speed controls for homogeneous dough.

- Sheet Rolling Machines: Adjustable rollers produce uniform noodle sheets with thickness control.

3.Noodle Forming & Cutting

- Extrusion Molds: Customizable dies for various noodle shapes (curly, flat, runden).

- Laser Cutting Technology: Precision cuts minimize waste and ensures uniform lengths.

4.Cooking & Drying Systems

- Steam Cooking Chambers: Rapid steaming (80–100°C) to gelatinize starch.

- Oil Fryers (or Hot Air Dryers): Energy-efficient fryers with oil filtration or air impingement dryers for crispiness.

5.Cooling & Seasoning Application

- Air Coolers: Rapid cooling to halt cooking processes.

- Seasoning Drum Coaters: 360° coating for even flavor distribution.

6.Packaging Solutions

- Automated Packing Machines: Nitrogen-flushing and vacuum-sealing options for extended shelf life.

- Case Packers: Robotic arms for palletizing and logistics optimization.

Key Features of Modern Production Lines

- IoT Integration: Real-time monitoring via sensors for predictive maintenance.

- Modular Design: Scalable modules for capacity adjustments (Z.B., 50–500 packs/min).

- Energieeffizienz: Heat recovery systems in fryers reduce energy costs by 30%.

- Food Safety Compliance: Stainless steel 304 construction, CIP (Clean-in-Place) Systeme.

II. Leading Manufacturers & Market Trends

The global instant noodles production line market is dominated by players in China, Japan, and Southeast Asia. Key manufacturers include:

- DT-Lebensmittelmaschine (China): Known for customizable turnkey solutions.

Pricing Factors

- Kapazität: Lines range from 50,000(small−scale)Zu5 Million (industrial).

- Automation Level: PLC-controlled systems vs. semi-automatic models.

- Anpassung: Tailored designs for regional tastes (Z.B., spicy, cup noodles).

- After-Sales Support: Training, spare parts, and warranties impact long-term costs.

Market Trends

- Healthier Options: Reduced-fat noodles, fortified with vitamins/fiber.

- Sustainability: Eco-friendly packaging and energy-saving technologies.

- Premiumization: Gourmet flavors and organic ingredients for niche markets.

III. DT-Lebensmittelmaschine: Your Trusted Partner

Warum wählen Sie DT Food Machine?

- Innovation & Anpassung

- Patented Technologies: Oil-saving fryers and high-speed cutters.

- Bespoke Solutions: From pilot-scale to 1,000 tons/day capacities.

- Quality & Compliance

- ISO 22000 & CE Certifications: Ensures food safety and EU standards.

- Durable Materials: Food-grade stainless steel for hygiene.

- Cost-Efficiency

- Energy-Saving Designs: Heat recovery reduces operational costs.

- Competitive Pricing: Direct-from-factory models without intermediaries.

- Global Support

- 24/7 Technical Service: Local teams in 50+ countries.

- Training Programs: Hands-on workshops for operators.

Case Study: Success in Southeast Asia

A DT Food Machine client in Vietnam increased production by 40% after installing a fully automated line. The energy-efficient fryer cut oil consumption by 25%, while the seasoning drum improved flavor consistency. ROI was achieved within 18 months.

IV.Abschluss

Investing in a high-quality instant noodles production line is a strategic move for businesses aiming to capitalize on the evergreen demand for convenience foods. By understanding the components, market trends, and choosing the right partner likeDT-Lebensmittelmaschine, you can achieve scalability, cost efficiency, and compliance.

Ready to Upgrade Your Production?

Contact DT Food Machine today for a free consultation and quote. Explore our designed to elevate your instant noodles business!