Kleine Pommes-Frites-Produktionslinie. Pommes-Frites-Anlage

Kleine Produktionslinie für Pommes Frites ist eine halbautomatische Pommes-Frites-Produktionslinie für kleine Unternehmen, mit einer Leistung von 100 kg/h, oder 150kg/h, bis zu 200 kg pro Stunde.

Pommes-Frites-Anlage ist kostengünstig, Es ermöglicht Unternehmen, klein anzufangen und schrittweise zu expandieren.

Anwendung: Kartoffelchips, Chips, und andere ähnliche Snacks.

Material: Edelstahl in Lebensmittelqualität 304

Kapazität: 50kg pro Stunde, 100kg pro Stunde, bis zu 200kg/h

Anwendung einer kleinen Produktionslinie für Pommes Frites

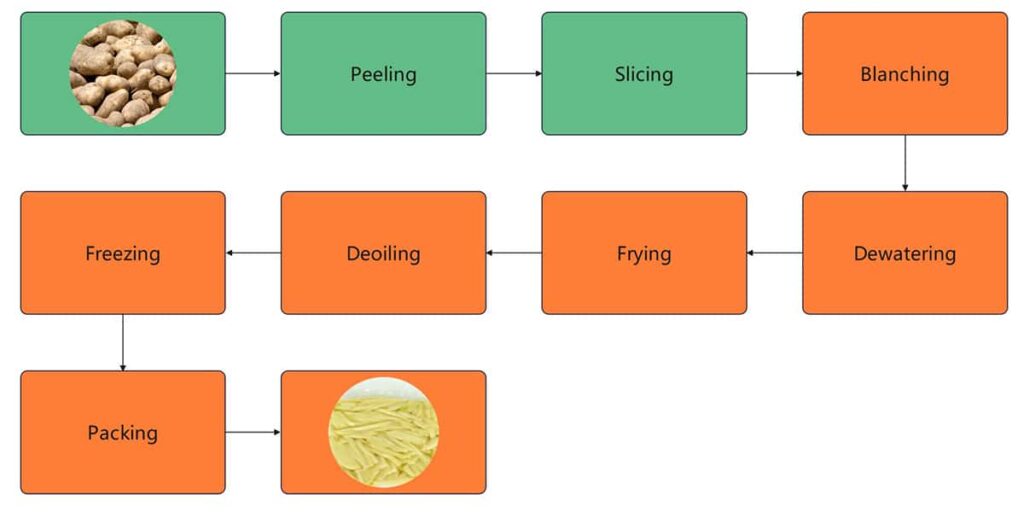

Die Pommes-Frites-Linienmaschine verwendet Kartoffeln mit niedrigem Wassergehalt und hohem Stärkegehalt als Rohstoffe, Und durch Waschen, Peeling, schneiden, Frittiervorgang, Schnellgefrier- und Vakuumverpackungsprozess, Die Pommes-Frites-Linie verwandelt die Rohkartoffel in köstliche Kartoffel-Pommes-Frites.

Die Produktionslinie für gefrorene Pommes Frites im kleinen Maßstab ist ideal für eine Vielzahl von Anwendungen. RRestaurants und Cafeterien benötigen Maschinen zur Herstellung von gefrorenen Pommes Frites, um eine zuverlässige Versorgung mit hochwertigen gefrorenen Pommes Frites zu gewährleisten. Während Lebensmittelverarbeitungsbetriebe eine Pommes-Frites-Anlage benötigen, um verschiedene IQF-Produkte herzustellen.

Und Tiefkühl-Pommes-Frites-Maschinen sind kostengünstig, sodass Anleger klein anfangen und schrittweise expandieren können. Was ist mehr?, Maschinen zur Herstellung von gefrorenen Pommes Frites sind äußerst flexibel für die Herstellung verschiedener Chips, wie Kartoffelchips, Bananenchips usw. Es ermöglicht Pommes-Frites-Herstellern, sich schnell an Marktveränderungen und Kundenanforderungen anzupassen. Dies macht die Produktionslinie für Pommes Frites zur idealen Wahl für Unternehmer und kleine Unternehmen.

Einführung in die Produktionslinie für gefrorene Pommes Frites im kleinen Maßstab

Beschreibung der Produktionslinie für Pommes Frites im kleinen Maßstab

Unsere kleine Produktionslinie für gefrorene Pommes Frites ist eine Komplettlösung für die Herstellung großer Mengen gefrorener und frittierter Produkte wie Kartoffel-Pommes, Kartoffelchips, und andere ähnliche Snacks. Und diese Pommes-Frites-Verarbeitungsanlage ist mit einer Vielzahl von Maschinen ausgestattet, die eine hohe Automatisierung gewährleisten, Einfachheit in der Bedienung, und erhebliche Energieeinsparungen.

Und die Verarbeitungslinie für Pommes Frites beginnt mit einer Wasch- und Schälmaschine, gefolgt von einer Schneidemaschine, Blanchiermaschine für Kartoffeln, Frittiermaschine, Entölungsmaschine, Schnellgefrierschrank und schließlich Verpackungsmaschine. Jede Maschine ist sorgfältig konzipiert, um die Leistung zu maximieren und gleichzeitig die höchsten Qualitätsstandards einzuhalten. Außerdem, Lebensmittelechte Materialien und fortschrittliche Technologie stellen sicher, dass die Pommes-Frites-Linie alle Gesundheits- und Sicherheitsvorschriften erfüllt.

Spezifikation einer halbautomatischen Pommes-Frites-Produktionslinie

Heizung Verfahren: Elektrische Heizung / Gasheizung

Maschinenmaterialien: Lebensmittelqualität 304 Edelstahlmaterialien, beste Qualität gefertigt

Kapazität: 50kg pro Stunde bis 200 kg pro Stunde, anpassbar

Empfehlung: Blanchierzeit: 60 Zu 90 Sekunden bei Wassertemperatur: 90 bis 95℃. Während, Bratzeit: 60s bei Ölbrattemperatur: 185℃. Einfrieren 30 Zu 50 Minuten pro Charge -30~-35C;

Größe der Pommes frites: 7mm bis 12mm einstellbar.

Paket: Vakuumverpackung, Plastikverpackung usw.

Platzbedarf in der Fabrik: Wir können die Produktionslinie basierend auf der Fabrikgröße und dem Grundriss anpassen

Diagramm der Produktionslinie für Pommes Frites im kleinen Maßstab

Vorteile der Pommes-Frites-Linie

- Kostengünstig: Unsere kleine Pommes-Frites-Produktionslinie ermöglicht es Kleinanlegern mit geringeren Investitionen, zu starten und später zu vergrößern. daher, Eine kleine Pommes-Frites-Anlage ist für kleine Unternehmen erschwinglicher als größere Optionen.

- Hohe Rentabilität: Unsere Pommes-Frites-Linie ist hochautomatisch und energiesparend, was die Gewinnpotenziale für Investoren maximiert.

- Qualitätsausgabe: Unsere Pommes-Frites-Maschine besteht aus lebensmittelechten Materialien und ist mit fortschrittlicher Technologie ausgestattet. Sie stellen sicher, dass das Endprodukt von höchster Qualität ist.

- Vielseitigkeit: Die halbautomatische Pommes-Frites-Produktionslinie ist flexibel für die Herstellung einer Vielzahl von Produkten, wie zum Beispiel Kartoffelchips, Chips, und Bananenchips.

Funktionen der Pommes-Frites-Linie

Pommes-Frites-Schälmaschine

Dies ist eine Kartoffelwaschmaschine. Es handelt sich auch um eine Zwiebel- und Kartoffelschälmaschine. Und es besteht aus lebensmittelechtem Edelstahl und ist für Kartoffeln verschiedener Größen geeignet, und auch für Süßkartoffeln etc. geeignet.

Automatische Kartoffelschäler entfernen schmutzige und dünne Kartoffelschalen vollständig und effizient, bei Schälgeschwindigkeit bis zu 98%.

Diese preisgünstige Kartoffelschälmaschine ist außerdem einfach zu bedienen und zu reinigen. Und der Arbeiter kann die Maschine stoppen, wenn der Schäleffekt zufriedenstellend ist. daher, Dies eignet sich gut für den Einsatz in halbautomatischen Kartoffelverarbeitungsanlagen.

Kartoffelschneider für Pommes

Die Kartoffelschneidemaschine eignet sich zum Schneiden von Kartoffeln in Scheiben von 7 mm bis 12 mm. Und auch der industrielle Pommes-Friteusen-Schneider kann zum Schneiden von Bananenchips verwendet werden, Süßkartoffelchips, Zwiebelringe und andere Wurzeln.

Mit diesem Kartoffelschneider aus Edelstahl, Die Größe der Kartoffelstäbchen ist gleichmäßig und es entsteht weniger Abfall.

Pommes-Frites-Blanchiermaschine

Dies ist eine Ausrüstung zum Blanchieren. Und die Funktion dieses Kartoffelblanchierers besteht darin, zu kochen 60 90 Sekunden lang die Kartoffelstange in Wasser einweichen 90 bis 95℃, behalten der ursprüngliche Geschmack und die frische Farbe.

Was ist mehr?, Blanchiergeräte verfügen über eine automatische Temperaturregelung, die eine gleichbleibende Qualität der Kartoffelstäbchen gewährleistet.

Außerdem, Wir haben eine elektrische Blanchiermaschine und auch eine Gemüseblanchierungsmaschine mit Gasheizung.

Der Blanchier aus Edelstahl entspricht den Standards der Lebensmittelproduktion.

Entwässerungsmaschine für Pommes Frites

Die Kartoffelentwässerungsmaschine entfernt nach dem Blanchieren Wasser von der Oberfläche der Pommes Frites. Und es handelt sich um eine Schnellzentrigugal-Entwässerungsmethode.

Und die Zentrifugalentwässerungsmaschine muss zur Verwendung auf festem Boden befestigt werden, und es verfügt auch über stoßfeste Geräte, um einen stabilen Betrieb zu gewährleisten.

Pommes-Frites-Frittiermaschine

Die Frittiermaschine ist eine Korbfrittiermaschine für kleine Kartoffelpflanzen. Und die Frittierzeit und -temperatur sind je nach Bedarf kontrollierbar und anpassbar. Die empfohlene Bratzeit beträgt 40 bis 60 Sekunden bei einer Öltemperatur von 185 °C.

Und es gibt eine elektrische Fritteuse und eine Fritteuse mit Gasheizung zur Auswahl. Außerdem, Diese Kartoffelfrittiermaschine ist für die Kapazität geeignet 100 bis 200 kg pro Stunde.

Zentrifugale Entölungsmaschine

Die Entölungsmaschine für Kartoffel-Pommes-Frites funktioniert nach dem gleichen Prinzip wie die Entwässerungsmaschine. Sie alle nutzen das Zentrifugalschleudern, um Öl aus frittierten Produkten oder Wasser aus gekochten Produkten zu entfernen, Die Pommes Frites sind nicht ölig und haben einen besseren Geschmack.

Die Entölungsmaschine ist außerdem mit stoßfesten Vorrichtungen ausgestattet und die Schleudergeschwindigkeit ist je nach Bedarf einstellbar.

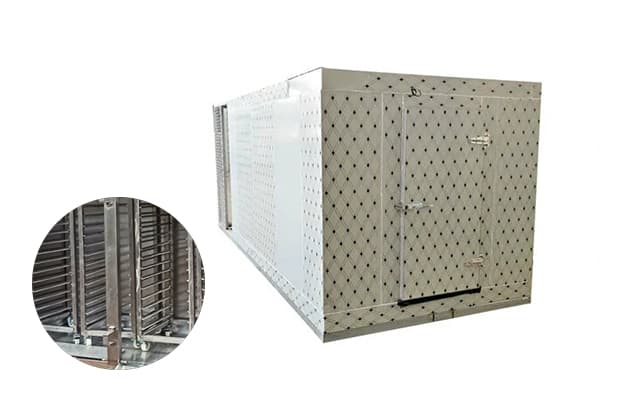

Gefrierschrank für Pommes Frites

Der Pommes-Frites-Gefrierschrank dient dazu, die Pommes Frites bei einer Temperatur von -30 bis -35 °C einzufrieren 30 Zu 50 Minuten, bis die Zentraltemperatur 18℃ beträgt.

Dies ist ein Batch-Gefrierschrank für kleine Pommes-Frites-Anlagen.

Verpackungsmaschine für Chips

Wir verfügen über Einkammer-Vakuumverpackungsmaschinen und Doppelkammer-Vakuumiergeräte, je nach Packungsgröße und Kapazitätsbedarf.

Es kann zum Vakuumverpacken von Pommes Frites verwendet werden, Knoblauch, frische Kartoffelscheiben, Karotten usw.

Parameter der Produktionslinie für gefrorene Pommes Frites im kleinen Maßstab

Als professioneller Hersteller von Pommes-Frites-Produktionslinien, Wir passen unsere Produktionslinie für gefrorene Kartoffeln an die Unternehmensgröße an. Hier sind die Daten unserer kleinen Produktionslinie für gefrorene Pommes Frites, die wir individuell anpassen können Produktionslinie für automatische Kartoffel-Pommes-Frites-Maschinen.

| Modell | DT-FF-50 | DT-FF-100 | DT-FF-200 |

| Roheingabe | 100KG | 200KG | 400KG |

| Chips-Ausgabe | 50KG | 100KG | 200KG |

| Stromspannung | 380V / 220V | ||

Maschinenfabrik zur Herstellung von Pommes Frites

Vorteil

Lebensmittelmaschinenfabrik aus einer Hand

30 Jahre R&D Geschichte

Stabile Maschinenleistung

Pünktliche Lieferung

Garantie

12 Monate Qualitätsgarantie

Lebenslanger technischer Support und Ersatzteilservice

Service

After-Sale-Unterstützung im Betrieb, Wartung.

Kostenlose Schulung online oder offline im Werk

Installation vor Ort im Werk des Kunden

Allgemeine Geschäftsberatung für neue Geschäftsplaner.

Lieferservice in das Land des Käufers

Preis der Produktionslinie für gefrorene Pommes Frites

Wir bieten wettbewerbsfähige Preise für unsere kleine Produktionslinie für gefrorene Pommes Frites, mit Optionen zur Anpassung der Maschinen an Ihre spezifischen Bedürfnisse. Kontaktieren Sie uns noch heute für ein detailliertes Angebot und um mehr über unsere Produkte und Dienstleistungen zu erfahren.

Verwandte Maschinen

Automatische Pommes-Frites-Produktionslinie, Mini-Kartoffelchips-Anlage, Produktionslinie für Bananenchips, Penauts Bratlinie. Durchlauffritteuse, Korbfritteuse, Automatische Fritteuse mit rundem Topf, kontinuierliche Frittiermaschine.