Kartoffelchip-Maschinen, Pommes-Frites-Maschinen, automatische Kartoffelchips-Linie

Kartoffelchipmaschinen Sind Kartoffelverarbeitungsgeräte von rohen Kartoffeln in knusprige gebratene Kartoffelchips.

Automatische Kartoffelchips -Linie Enthält Kartoffelwasch- und Schälenmaschine, Chipsschneidermaschine, Blanchiermaschine für Kartoffeln, Kartoffelchipsentwässerungsmaschine, Kartoffelchips Fritteusen, Entölungsmaschine, Kühlmaschine, Gewürzmaschine Kartoffelchips, Kartoffelchips Verpackungsmaschine und Hilfsgeräte und Funktionen, um die gesamte Linie vollautomatisch zu machen und kontinuierlich zu arbeiten.

Angewendet auf: Kartoffelchips, Pommes frites, Kochbananen -Chips usw..

Kapazität: 50-100kg/h, 100-150kg/h, 200-250kg/h, 350-400kg/h, 450-500kg/h, und höhere Kapazität.

Anwendung von Kartoffelchipmaschinen

Kartoffelchipmaschinen werden in Kartoffelchipsfabrik mit größerer oder mittlerer Kartoffelverarbeitungsanlage verwendet. Wegen der hohen Produktionseffizienz und der hygienischen Lebensmittel,Die vollautomatische Kartoffelchips -Linie sorgt dafür, dass die Anleger weniger Produktionskosten und mehr Marktanteile haben, Deshalb eine bessere Investitionsrendite gewinnen.

Und, kleine Kartoffelchips machen Maschine ist gut für Lebensmittelverarbeitungsunternehmen, die vorhaben, in Kleinunternehmen zu beginnen.

Außerdem, Die Maschine für Chips kann auch die Linie so anpassen, dass Fingerchips hergestellt werden, Bananenchips , Süßkartoffelchips, usw.

Kartoffelchips -Maschine Einführung

Kartoffelchips -Maker Beschreibung

Kartoffelchips Herstellung Maschine ist eine Kartoffelverarbeitungslösung beim Kartoffelwaschen, Peeling, blanchieren, Braten, Gewürz und Packen. Und die Chipslinien sind hoch Kapazität, Super -Effizienz mit qualifizierten und hygienischen Lebensmitteln.

Um unterschiedliche Geschäftsanforderungen zu erfüllen, Wir haben eine semiautomatische Kartoffelchips-Produktionslinie mit Kapazität 20-50 kg/h oder 50-100 kg/h entworfen. Wir haben aber auch eine vollautomatische Maschine für Kartoffelchips mit einer Kapazität von bis zu 500 kg/h entwickelt und eine höhere Kapazität kann individuell angepasst werden.

Kartoffelchips -Maker -Maschinespezifikation

Heizmethode: Elektrische Heizung / Gasheizung

Maschinenmaterialien: Lebensmittelqualität 304 Edelstahlmaterialien, beste Qualität gefertigt

Ölheiztemperatur: 0℃ bis 300℃ (Fahrenheit 32°F bis 572.0 °F)

Verhältnis von Kartoffeln und Kartoffelchips: 4 : 1 für Referenzen.

Kapazität: 50Kg/h bis 500 kg/h (Der Chiphersteller mit höherer Kapazität kann individuell angepasst werden)

Platzbedarf in der Fabrik: Wir können die Produktionslinie basierend auf der Fabrikgröße und dem Grundriss anpassen.

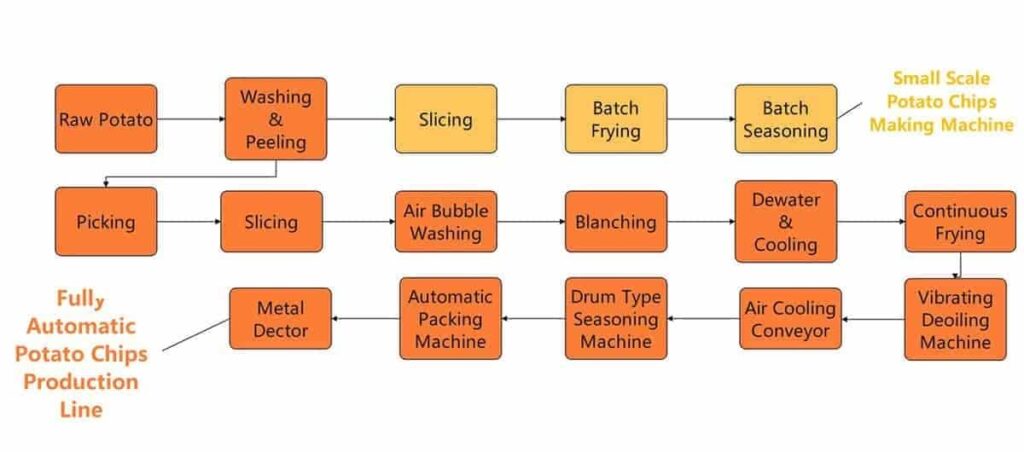

Kartoffelchips Produktionslinienflussdiagramm

Kartoffelchip -Produktionslinienfunktionen

Kartoffelschaltmaschine

Für die Produktionslinie des Einkaufszentren -Skala -Chips, BAtch -Kartoffelschaltmaschinen Hat mehr Vorteil eines effizienten Waschens und einer höheren Schälenrate als manuelle Arbeiten.

Und für eine vollautomatische Kartoffelchips -Produktionslinie, Es ist notwendig, die kontinuierliche Kartoffelwasch- und Schälenmaschine zu nehmen. Arbeiten mit einem Aufzug, Es wird die kontinuierliche rohe Kartoffel -Fütterung erkennen, Waschen, Peeling- und Entladungsprozess.

Außerdem, Die Peeling -Maschine vom Typ Sprial Drücken Sie den Kartoffel -Foward und die Entladung vom anderen Ende zu Förderbändern, bevor Sie den Prozess schneiden.

daher, Automatische Kartoffelschaltmaschine wird in der Produktionslinie mit mittlerer und größerer Kapazität Kartoffelchips verwendet.

Darüber hinaus, Es ist zum Waschen und Schälen von Kartoffeln geeignet, Süßkartoffel, Maniok, Ingwer, Zwiebel, Karotten usw.

Chips Slicer -Maschine

Kartoffelschneidermaschine kann die Kartoffelscheiben mit einer gleichmäßigen Dicke schneiden. Und die Schichtdicke kann nach Bedarf eingestellt werden.

Außerdem, Es gibt verschiedene Modelle der Kartoffel -Chip -Cutter -Maschine, die auf Produktionskapazität und Bedürfnissen basieren.

Blanchierkartoffeln vor dem Braten

In einer automatischen Kartoffelchips -Produktionslinie mit großer Kapazität, Die Blanchiermaschine spielt eine wichtige Rolle, um die Chipfarbe zu schützen und Gütergeschmack zu bleiben.

Kartoffelchips Verzweigungszeiten sind ungefähr 5 bis 15 Minuten bei Heißwassertemperatur 70 ℃ (158.0 °F)

Es gibt eine kontinuierliche Verzweigungsmaschine mit Gasheizung und kontinuierlicher Verzweigungsmaschine mit elektrischer Heizung für die Auswahl des Kunden.

Außerdem, Die Verzweigungsmaschine eignet sich auch nicht nur gut für verzweigte Kartoffelchips, aber auch Bananenchips, Pommes Frites und andere Materialien.

Kartoffelentwässerungsmaschine

Die Luftkühlmaschine entfernt das Wasser und kühlt die Temperatur von verzweigten Kartoffelchips vor dem Braten ab.

Und bessere Wirkung zu haben, Ein vibrierender Enttäsungsmakine ist notwendig.

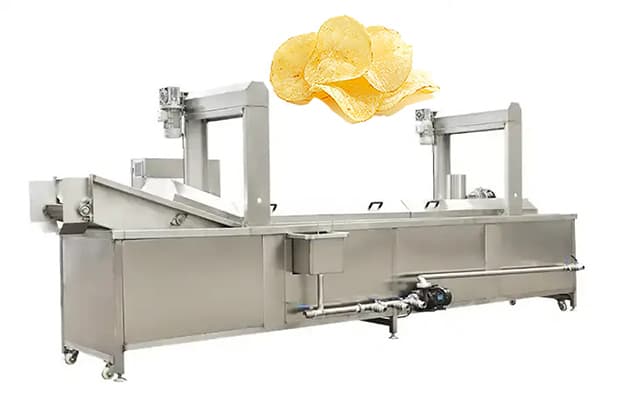

Kartoffelbratenmaschine

Für kleine Kartoffelchips Pflanze, Die semiautomatische Breitlinie ist eine ideale Wahl, die rund um den runden Topfbraten enthält.

Jedoch, Für automatische Chips -Produktionsanlagen, Die kontinuierliche Frittiermaschine ist erforderlich, um die Frittierzeit kontinuierlich mit größerer Kapazität und weniger Arbeiten zu halten. Und die gebratenen Chips müssen mit einer geratenen Farbe und einem guten Geschmack eine höhere Qualität sein. Außerdem, das Öl -Nachfüllsystem, Ölrecycle -System, Das Ölfiltersystem und das Self -Reinigungssystem für Maschinen verbessern die Produktionseffizienz erheblich, Verlängern Sie den Ölverbrauch und Bettter -Qualitäts -Chips.

Deiling -Maschine

Vibrierende Enttülenmaschine ist Neccessory, um Öl nach dem Braten auf gebratenen Chips zu entfernen.

Weil, Die gebratenen Chips von Frittierungen tragen normalerweise einige Öle. daher, Die Vibrationsmaschine mit Ölempfangteller ist gut, um das Öl von der Chips zu enttäuschen und die Produktionsstelle sauber zu halten.

Was ist mehr?, Während des Vibrationsprozesses, Die Chips bewegen Foward und verbreiten sich sogar auf den nächsten Prozess.

Kühlmaschine

Der Kühlförderer ist mit Beatmungsgeräten installiert, die Wind in Chips blasen. Daher der Temperaturabfall der Chips durch natürlichen starken Wind tragend. Dies ist ein wichtiger Prozess vor dem Gewürz- und Verpackungsprozess. Vollkühlende Chips sind kripsiger und haben länger Haltbarkeit.

Optionales Design: Das winddichte Netz ist notwendig, um zu vermeiden, dass Chips die Förderbande abblasen.

Und Ölempfängerplatte unter dem Kühlförder.

Kartoffelchip-Gewürzmaschine

Drum -Gewürzmaschine funktioniert mit Pulvergewürzen, würziges Gewürz, Salz, und kann auch mit Ölsprühen usw. angepasst werden. nach Produktionsbedürfnissen.

Für Chips Linie, Nach dem Abkühlen der Chips, Ein Förderer schickt die Chips notwendig, um Drum kontinuierlich zu würzen, um die Gewürze gleichmäßig mit Chips zu mischen.

Und im Steckdose, Es gibt Mesh -Design, damit Addtional -Gewürze und Abfall auf eine Empfangsplatte ausfallen können. Aufgrund dieses Designs, Die Chips sind nur mit der richtigen Menge an Gewürzen und dem großartigen Geschmack verbunden.

Automatische Maschine mit Gewichten packen, Füllung und Taschenherstellung

Chips automatisch in Plastiktüten packen, Die Auto -Chips -Verpackungsmaschine ist eine ideale Wahl. Normalerweise, Die Verpackungsmaschine für Auto -Chips muss Aufzug enthalten, Multi-Head-Wiegen, flach, Geräte zum Taschenherstellen mit Datumsdruckfunktion, und ein Endproduktförderer.

Und, zum Verpacken von Chips, Die Stickstofffunktion ist notwendig, um Chips mit langer Haltbarkeit zu halten und während des Transports Schutz zu bieten.

Was ist mehr?, Die Chips -Packungsmaschine hat einen Vorteil von hoher Effizienz, genaues Wiegen, und kontinuierlich mit Chips -Produktionslinie arbeiten.

Parameter der Kartoffelchips-Maschine

Vollautomatische Kartoffelchips Produktionslinie DT-PC-500, Kapazität 450-500 kg/h als Referenz.

| Name | Stromverbrauch | Spannungsrate |

| Aufzug mit Bunker | 0.75 kW | 380V 50 Hz 3PH, in der Lage zu anpassen |

| Kartoffelwasch- und Schälenmaschine | 4.75 kW | 380V 50 Hz 3PH, in der Lage zu anpassen |

| Förderer pflücken | 0.75 kW | 380V 50 Hz 3PH, in der Lage zu anpassen |

| Kartoffelhip -Cutter -Maschine | 1.1 kW | 380V 50 Hz 3PH, in der Lage zu anpassen |

| Blanchiermaschine | 70 kW | 380V 50 Hz 3PH, in der Lage zu anpassen |

| Vibrierende Entwässerungsmaschine | 1.5KW | 380V 50 Hz 3PH, in der Lage zu anpassen |

| Luftkühlungsdehydrationslinie | 15 kW | 380V 50 Hz 3PH, in der Lage zu anpassen |

| Aufzugsförderer vor dem Braten | 0.75 kW | 380V 50 Hz 3PH, in der Lage zu anpassen |

| Kartoffelchips Frittiermaschine | 204.5 kW | 380V 50 Hz 3PH, in der Lage zu anpassen |

| Vibrations-Entölungsmaschine | 1.5 kW | 380V 50 Hz 3PH, in der Lage zu anpassen |

| Luftgekühlte Trocknungslinie | 8 kW | 380V 50 Hz 3PH, in der Lage zu anpassen |

| Eelvator zum Gewürz | 0.75 kW | 380V 50 Hz 3PH, in der Lage zu anpassen |

| Gewürzmaschine | 1.5 kW | 380V 50 Hz 3PH, in der Lage zu anpassen |

| Vollautomatische Kartoffelchips-Verpackungsmaschine | 6.5KW | 380V 50 Hz 3PH, in der Lage zu anpassen |

Hersteller von Kartoffelchips Linien

Vorteil der Frittiermaschinenfabrik

Lebensmittelmaschinenfabrik aus einer Hand

30 Jahre R&D Geschichte

Stabile Maschinenleistung

Pünktliche Lieferung

Garantie

12 Monate Qualitätsgarantie

Lebenslanger technischer Support und Ersatzteilservice

Service

After-Sale-Unterstützung im Betrieb, Wartung.

Kostenlose Schulung online oder offline im Werk

Installation vor Ort im Werk des Kunden

Allgemeine Geschäftsberatung für neue Geschäftsplaner.

Lieferservice in das Land des Käufers

Kartoffelchips Produktionspreis

Wir verfügen über ein professionelles technisches Ingenieurteam und ein Produktentwicklungsteam, die unsere Produktionslinie für eine höhere Effizienz modernisieren, weniger Produktion und bessere Benutzerzufriedenheit. Außerdem, Wir verstehen die Bedürfnisse unserer Kunden und reagieren schnell auf sie mit der richtigen Lösung für ihr Unternehmen.

Sie sind am meisten begrüßt, um unser Team jetzt zu kontaktieren, um eine Frittierlösung zu erhalten und zu zitieren.

Verwandte Maschinen

Produktionslinie für Pommes Frites, Produktionslinie für Bananenchips, Penauts Bratlinie. Durchlauffritteuse, kleine Kartoffelchips Produktionslinie