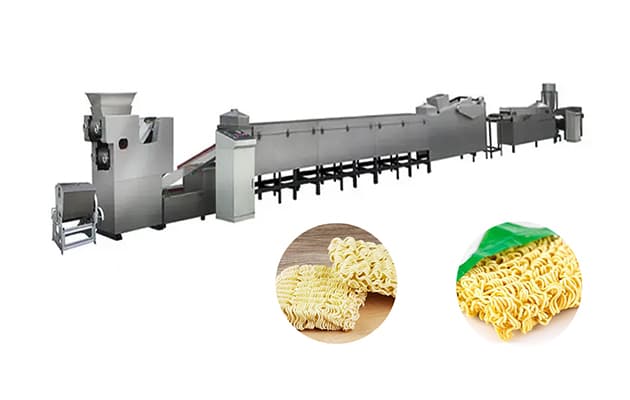

Instant Noodle Production Line Automatic fried Maggi Instant Noodle Line Indomie Noodle Line

Instant noodle production line includes raw materials pumping, measuring and weighing system, mixing and dough ripening, noodle making, steaming, frying or drying, تبريد, packing system etc.

طلب: Fried Instant Noodle, Ramen Noodle, Maggi Noodle, Indomie Noodle, Non-Fried Instant Noodle,

سعة: 11,000 Bags/8Hours to 260,000 Bags/8Hours (60g for example)

Instant Noodle Production Line Application

Instant Noodle Production Line is a modern manufacuring way to produce delicious, high-quality instant noodles at high capacity, low consumption and high automation.

And automatic noodle line 200,000 bags/8hrs (60ز) is widely used in instant noodle manufacturers who prefer the large-scale of Instant Ramen. And indomie instant noodle making machines 100,000 bags/8hrs are suitable for food processing plants that specialize in the production of various types of noodles and pasta. What is ore, our small maggi noodle production lines 11000bag/8hrs are new business ideas for catering companies who requires high quality noodles, retail and wholesale who intend to diversify their product range.

بجانب, the instant noodle lines could make fried instant noodle, non-fried instant noodle, maggi noodles, indomie noodle, round shape noodle cake, noodle bricks, square noodle cake etc with noodle cake weight from 30g to 120g and customizable.

And our instant noodle packing machine could do bag type package, cup noodle package and pack instant noodle in tray.

Fried Instant Noodle Production Line Introduction

Instant Noodles Production Line Description

Instant Ramen production line includes raw materials pumping system, ingredients measuring and weighing system, wheat flour mixing and dough ripening, noodle making system, noodle steaming system, noodle cake frying system (fried instant noodle) or drying system (non-fried instant noodle), cooling system, packing system etc. Besisdes, the seasoning and saurce making and packing solution is also available upon customer request.

Fully Automatic Instant Noodle Plant Main Function

PLC Program Control: Provides whole instant noodle production process from ripening to cooling, with seamless operation and easy troubleshooting.

Soaking Flavoring Technology: Enhances the taste and aroma of noodles, making them more appetizing and delicious.

Touch Screen Delivery Presetting: Enables operators to preset delivery parameters with ease, ensuring precision and consistency throughout the production process.

Photoelectric Tracking: Utilizes photoelectric sensors to monitor and adjust the production line in real-time, ensuring optimal performance and product quality.

Frequency Control: Allows for smooth acceleration and deceleration of the production line, reducing wear and tear on equipment and maintaining consistent product quality.

Instant Noodle Processing Line Specification

Steaming and Frying Method: التدفئة الكهربائية / Gas Heating /Boiler Heating, depending on production line model and customer requirement.

مواد الآلة: درجة الغذاء 304 مواد Streel غير القابل للصدأ, أفضل جودة صنعت

Oil Heating Temperature: 0℃ to 300℃ (Fahrenheit 32°F to 572.0 °F )

سعة: 11,000 bags/ 8hrs, 20,000 bags/8hrs, 30,000 bags /8hrs, 60,000 bags/8hrs, 80,000 bags/8hrs, 100,000bags /8hrs, 120,000bags/8hrs, 160,000bags/8hrs, 200,000basg/8hrs, 260,000bags/8hrs and higher capacity customizable. (taken 60g noodle for example, the production line capacity varies according to desired noodle cake dimension and weight)

Noodle Cake Shape: Round shape, brick noodle, square noodle shape.

Noodle Cake Weight: 30g to 120g and accept customized.

نوع الحزمة: in plastic bag, bowl, cup, plastic tray.

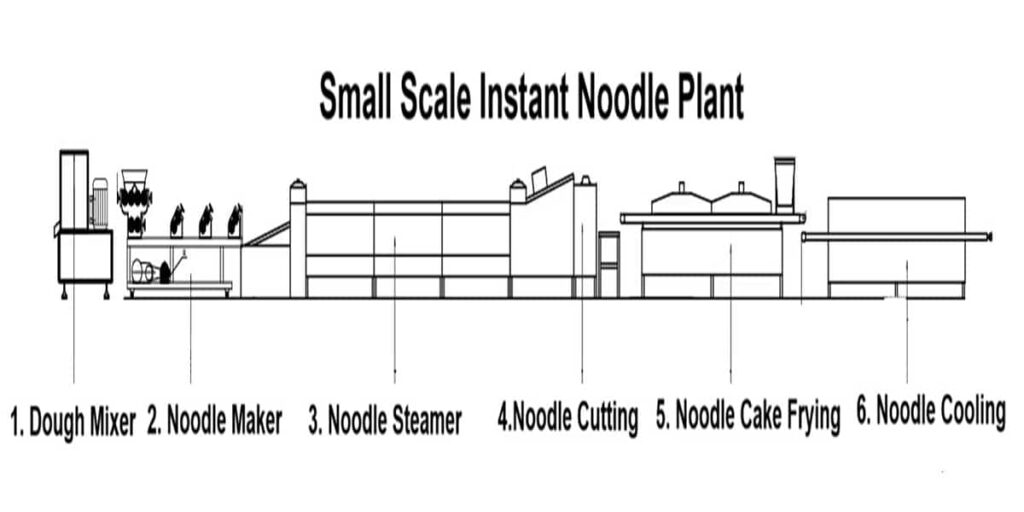

Fried Instant Noodle Production Line Flow Chart

Instant Noodle Machine Features

1. Dough Mixer

Elliptic Blade Double-Shaft Double-Speed Dough Maker

Ensures consistent dough curing with a large amount of water, therefore, the noodles are smooth texture and good elasticity.

2.Instant Ramen Sheeter and Forming

9 Pairs of Chilled Hard Alloy Rollers:

Making precise pressing and shaping of noodles,and ensuring a uniform thickness and texture of noodle strands.

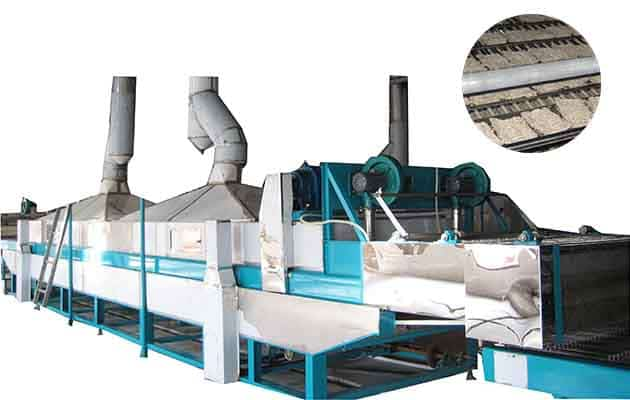

3. Instant Noodle Steaming Tunnel

Using water seal, no leakage. It is independent drive and there is no need the turn off machine when adjusting the length of dough.

4. Ramen Noodle Frying Tunnel

Automatic Frying Temperature Control: Maintaining a consistent oil frying temperature, which makes golden-brown noodles with a perfect crunch.

Instant Noodle Maker Parameter

| سعة (60g Noodle) | قوة | Steam Consumption | البعد (single layer steamer) Length*Width*Height | البعد (multi- layer steamer) Length*Width*Height |

| 30,000pieces/8h | 42KW | 1000-1200KG/H | 50*5*4م | 40*5*4م |

| 60,000pieces/8h | 56KW | 1200-1400KG/H | 55*5*5م | 45*5*4م |

| 80,000pieces/8h | 68KW | 1300-1500KG/H | 65*6*4م | 55*6*4م |

| 120,000pieces/8h | 83KW | 1800-2000KG/H | 75*6*4م | 65*6*4م |

| 160,000pieces/8h | 106KW | 2000-2200KG/H | 85*7*4.5م | 75*7*4.5م |

| 200,000pieces/8h | 114KW | 2400-2600KG/H | 90*8*4.5م | 80*8*4.5م |

| 230,000pieces/8h | 125KW | 2600-2800KG/H | 100*8*4.5م | 90*8*4.5م |

Indomie Making Machine Manufacturer

ميزة

مصنع آلات الغذاء من نقطة واحدة

30 سنوات ص&D التاريخ

أداء الآلات مستقرة

في الوقت المحدد

يضمن

12 شهور ضمان الجودة

خدمة الدعم الفني لحياة كاملة وخدمة قطع الغيار

خدمة

دعم ما بعد البيع في العملية, صيانة.

تدريب مجاني عبر الإنترنت أو خارج الخط في المصنع

تركيب في الموقع في مصنع العميل

المشورة الإجمالية للمخطط التجاري الجديد.

خدمات التوصيل إلى بلد المشتري

Noodle factroy design, recipe providing, and seasoning and packing solution providing.

Instant Noodle Machine Price

We have professional technical engineer team and product develope team to updgrating our production line for higher efficency, إنتاج أقل وأفضل مرضية للمستخدم. بجانب, نحن نتفهم ونستجيب سريعًا لاحتياجات العملاء مع الحل الصحيح لأعمالهم.

You are most welcomed to contact our team now for a instantnoodle production solution and quote.

الآلات ذات الصلة

small scale instant noodle production line, noodle maker, stick noodle production line, macaroni pasta production line.